Integral suction filtration and distribution device for manufacturing initiating explosives

A technology for priming explosives and vacuuming devices, applied in explosives, explosives processing equipment, offensive equipment, etc., can solve the problems of complex overall structure, high production cost, and heavy workload, and achieve improved production efficiency, low cost, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

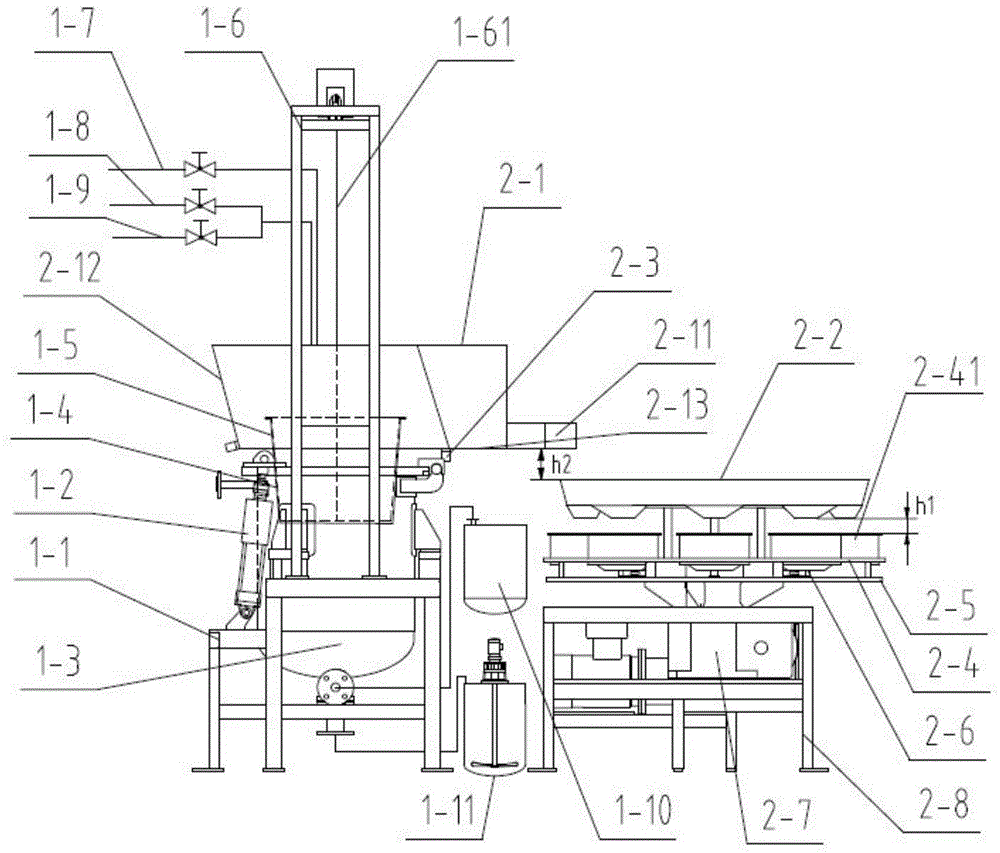

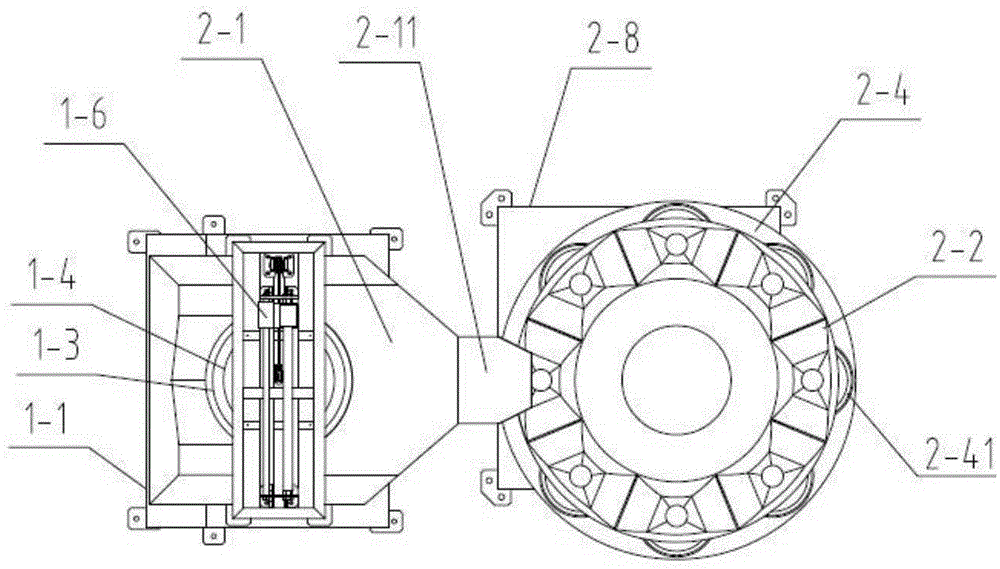

[0037] An integrated device for suction, filtration and separation discs made of primary explosives, see figure 1 as well as figure 2 , including suction filter components, sub-disc components and controllers.

[0038] The suction filter components include a suction filter base 1-1, a jacking cylinder 1-2, a suction filter tank body 1-3, a suction filter funnel 1-4, a filter cloth 1-5, a lifting device 1-6, and a raw material delivery device , a filtrate recovery device and a vacuum pumping device, the raw material conveying device includes a material conveying pipe 1-7, an alcohol conveying pipe 1-8 and a water conveying pipe 1-9, and the material conveying pipe 1-7, the alcohol conveying pipe 1-8 And the water delivery pipes 1-9 are equipped with valves, which can realize the entry of the primary explosive synthetic feed liquid into the suction filter funnel and its single or mixed washing. The water delivery pipes 1-9 can transport deionized water or pure water according to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com