Compound aluminum-base lubricating grease composition and preparation method

A lubricating grease composition and composite aluminum technology, applied in lubricating composition, petroleum industry, etc., can solve the problems of easy drying of bentonite grease, slow change of consistency temperature, large oil separation of composite aluminum-based grease at high temperature, etc., to achieve Good high temperature performance, stable product quality, solve the problem of high temperature oil separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

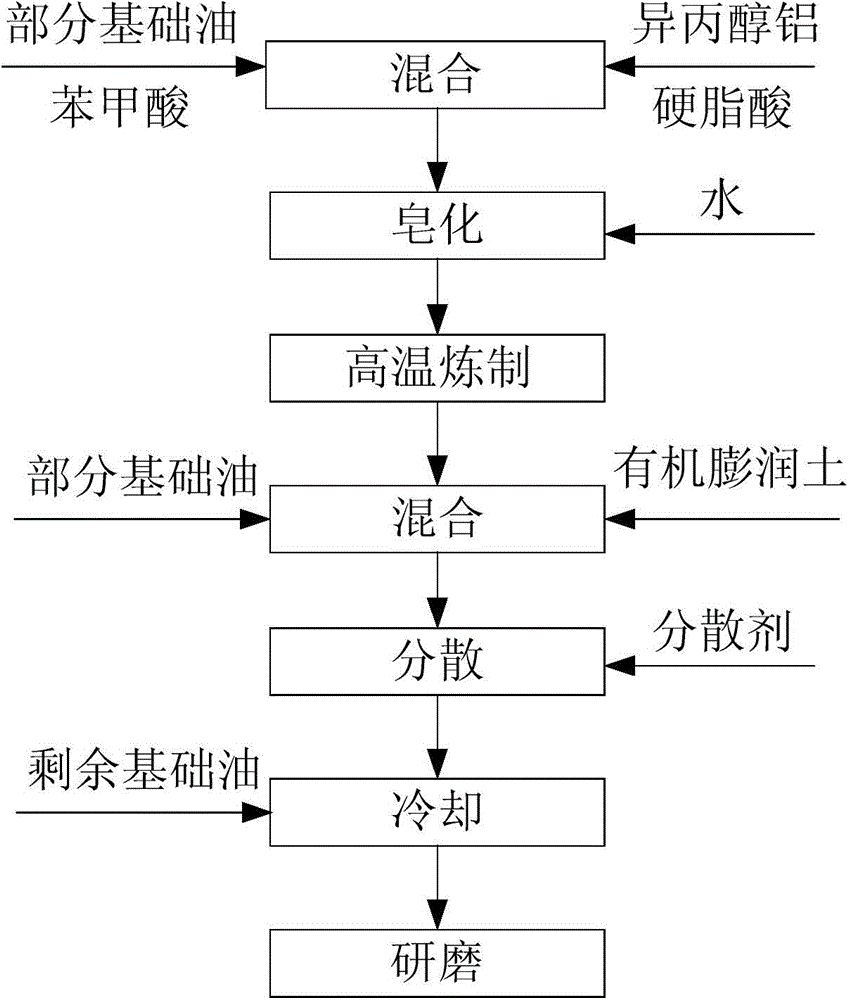

Method used

Image

Examples

Embodiment 1

[0035] Add 8Kg of refined mineral oil, 0.36Kg of stearic acid, 0.27Kg of aluminum isopropoxide, and 0.16Kg of benzoic acid into the reaction kettle, stir and heat to 90-120°C, and keep it for 60 minutes, then add 0.1Kg of water, and continue to stir the reaction 90min, heat up to 195-215°C, refine at this high temperature for 30min, add 5Kg of refined mineral oil, add 2Kg of organic bentonite when the temperature drops to about 150°C, add 2Kg of acetone after 30min, add the remaining 4Kg of refined mineral after dispersing for 40min Oil and sulfurized isobutylene 0.1-1Kg, benzotriazole fatty acid amine salt 0.2-2Kg and diphenylamine 0.1-0.6Kg, after mixing and stirring evenly, grinding and degassing to obtain the finished composite aluminum-based grease A.

Embodiment 2

[0037] Add 8Kg of mixed oil of mineral oil and synthetic oil, 0.36Kg of stearic acid, 0.27Kg of aluminum isopropoxide, and 0.16Kg of benzoic acid into the reaction kettle, stir and heat to 90-120°C, keep warm for 60min, then add 0.1 Kg water, continue to stir and react for 90 minutes, heat up to 195-215°C, refine at this high temperature for 30 minutes, add 5Kg of refined mineral oil, add 1Kg of organic bentonite when the temperature drops to about 150°C, add 1Kg of acetone after 30 minutes, and disperse for 40 minutes Then add the remaining 2Kg of refined mineral oil, 0.1-1Kg of sulfurized isobutylene, 0.2-2Kg of benzotriazole fatty acid amine salt and 0.1-0.6Kg of phenothiazine, mix and stir evenly, grind and degas to obtain the finished composite aluminum-based grease B.

Embodiment 3

[0039] Add 8Kg of refined mineral oil, 0.36Kg of stearic acid, 0.27Kg of aluminum isopropoxide, and 0.16Kg of benzoic acid into the reaction kettle, stir and heat to 90-120°C, keep warm for 60 minutes, add 0.1Kg of water, and continue stirring React for 90 minutes, heat up to 195-215°C, refine at this high temperature for 30 minutes, add 5Kg of refined mineral oil, add 2Kg of organic bentonite when the temperature drops to about 150°C, add 1.8Kg of propylene carbonate after 30 minutes, disperse for 40 minutes, then add The remaining 4Kg of refined mineral oil, 0.1-1Kg of phenyl-α-naphthylamine, 0.2-2Kg of benzotriazole fatty acid amine salt and 0.1-0.6Kg of phenothiazine are mixed and stirred evenly, then ground and degassed to obtain the finished composite aluminum-based lubricant Fat C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com