Full-face tunnel boring machine

A technology of full-section roadheader and roadheader, which is applied to shaft equipment, mining equipment, earth-moving drilling, etc., can solve the problems of inability to tunnel construction, heavy weight, and difficult transportation, and achieves reduced transportation difficulty, light weight, and small volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

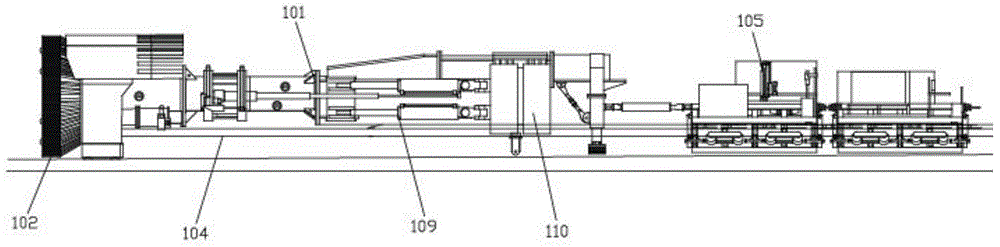

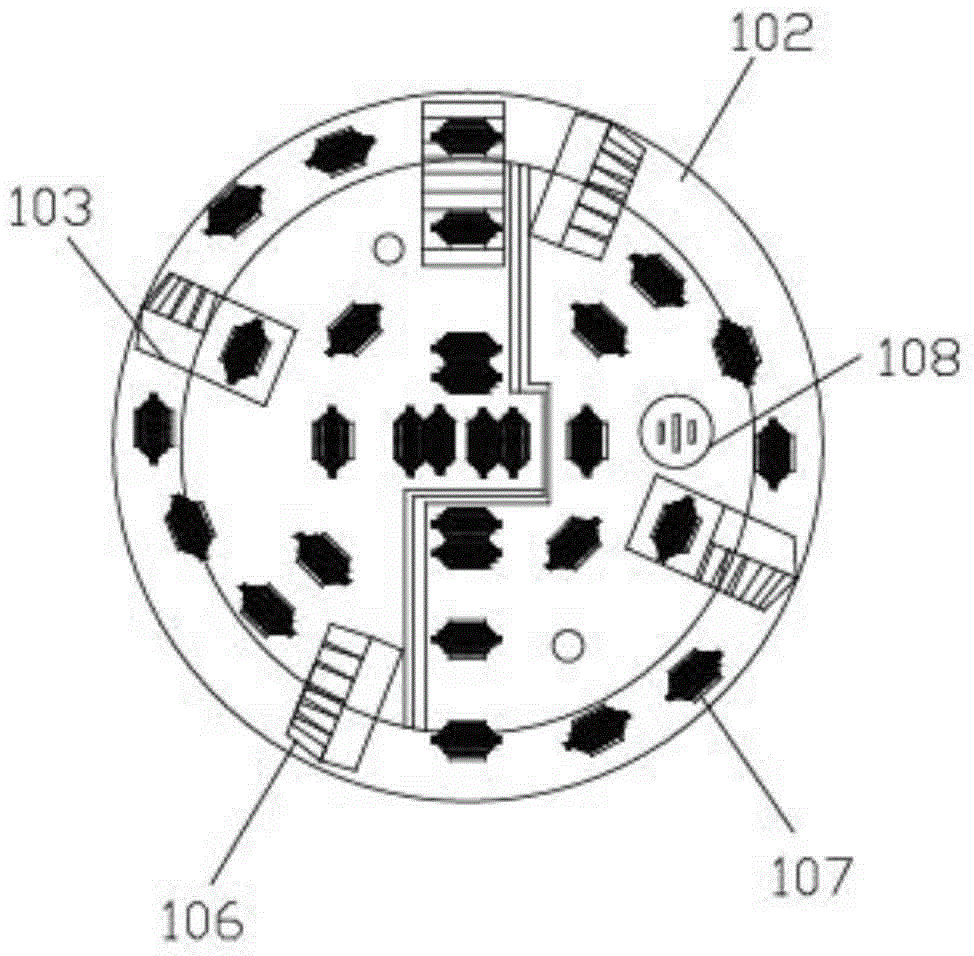

[0015] Please refer to figure 1 , a full-face roadheader provided by an embodiment of the present invention includes a roadheader body 101, the head of the roadheader body 101 is provided with a cutterhead 102, and the cutterhead 102 is detachably connected to the roadheader body 101 , the roadheader main body 101 is formed by detachable connection of a plurality of main body modules.

[0016] In this embodiment, since the main body 101 of the roadheader is detachably connected by a plurality of main body modules, the main body 101 of the roadheader can be disassembled into a plurality of main body modules for transportation separately. It is light, so it reduces the difficulty of transportation, which is beneficial to meet the hoisting requirements of the vertical shaft, so that the full-face roadheader provided by the embodiment of the present invention can be used in the roadway with the vertical shaft structure.

[0017] In this embodiment, when in use, the main modules o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com