A centrifugal blower air guide impeller assembly

A technology of air guide impeller and blower, applied in the field of machinery, can solve the problems of unfavorable air flow, influence of tightening torque accuracy, influence of air flow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

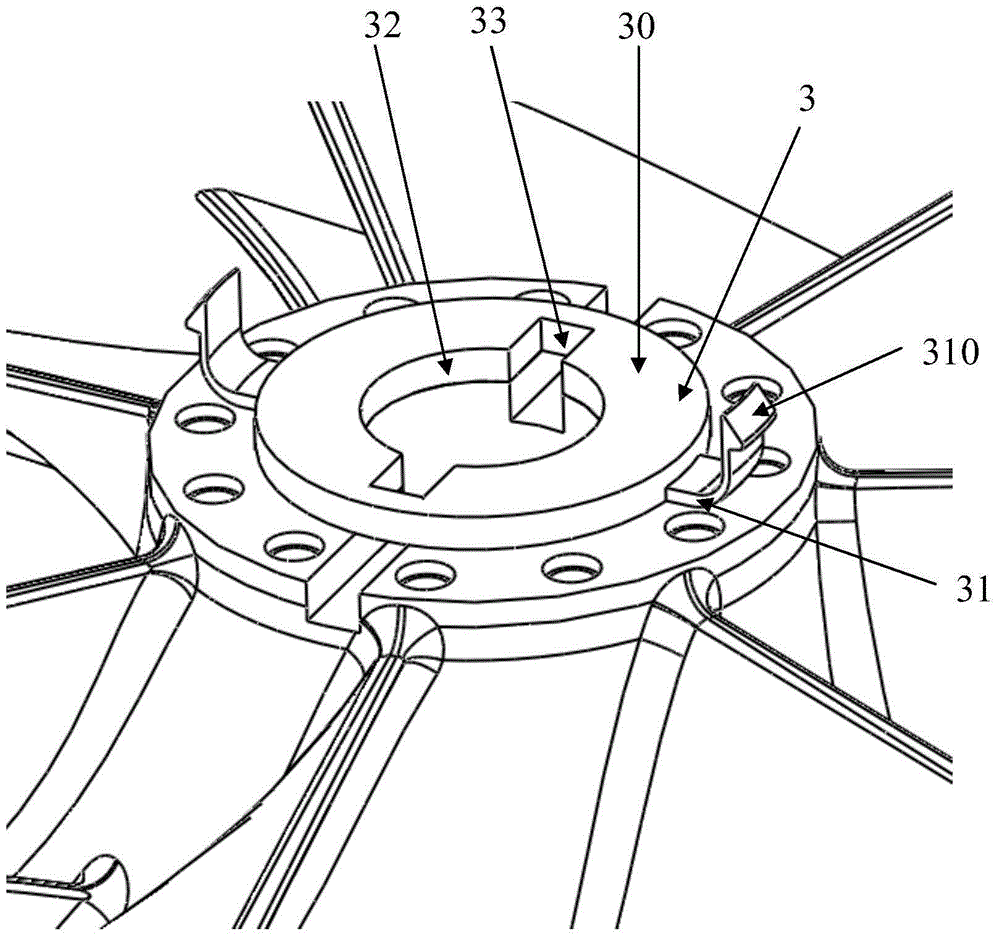

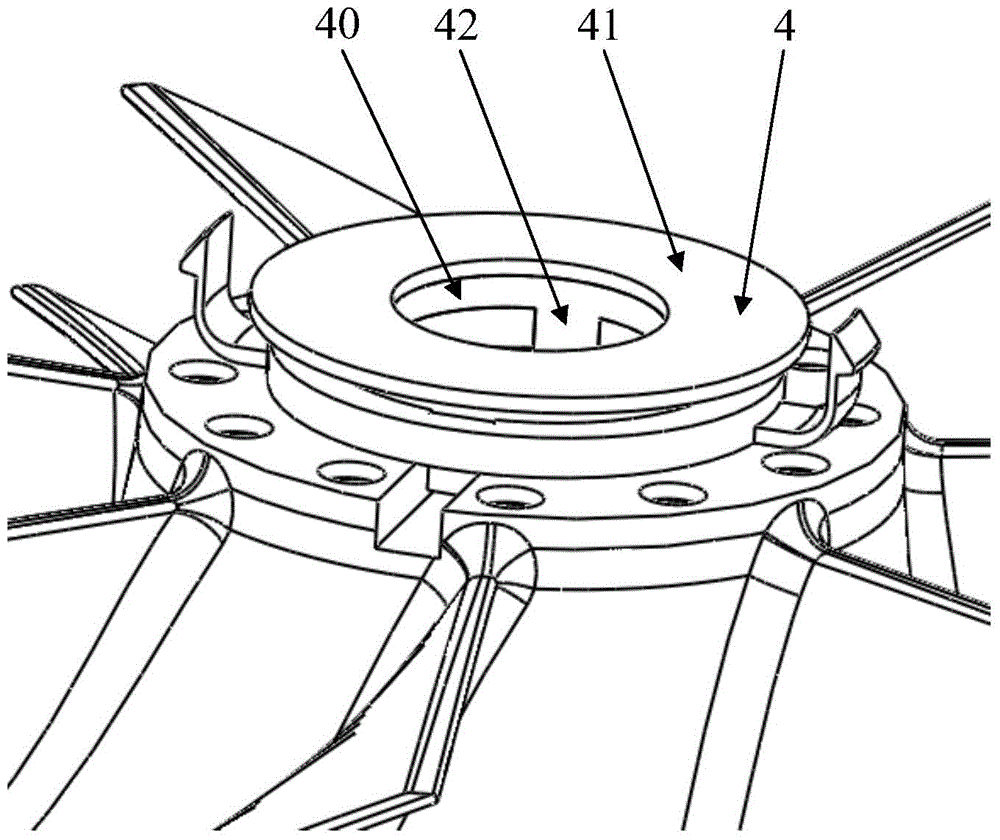

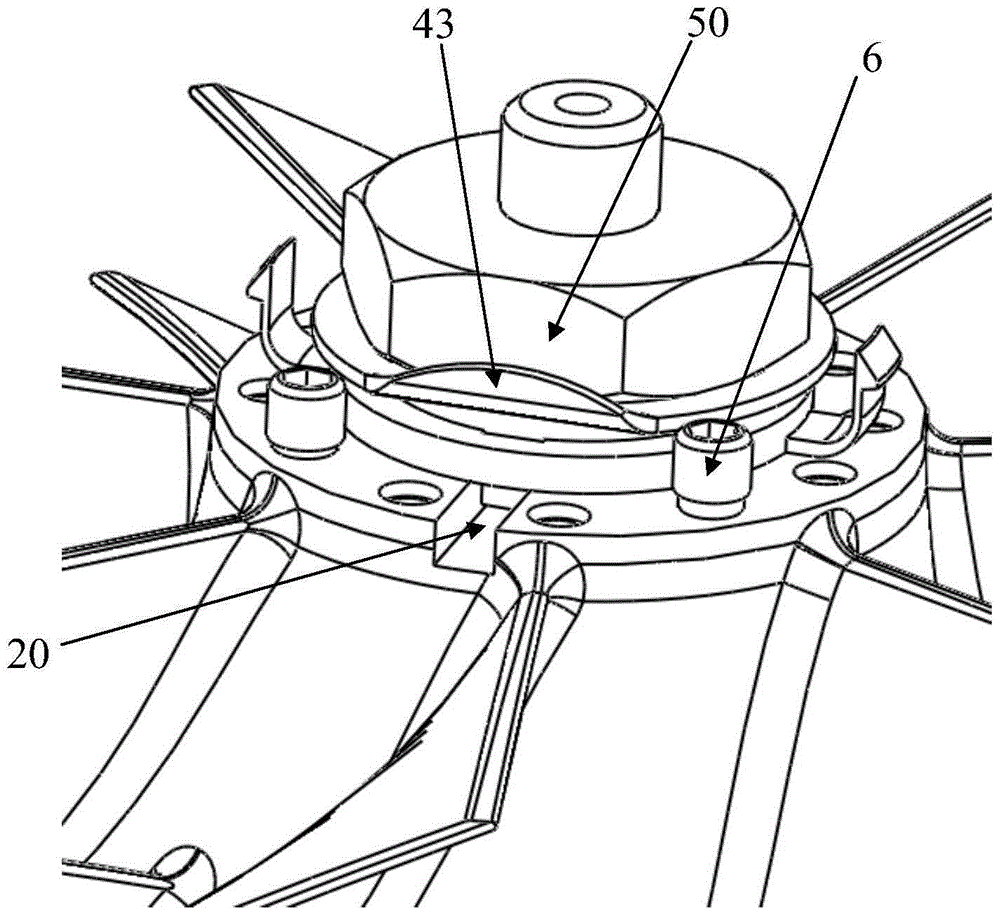

[0023] Please refer to Figure 1 to Figure 7 As shown, the air guide impeller assembly of the centrifugal blower of the present invention includes a rotor 1; an impeller 2 mounted on the rotor 1; a circlip 3 mounted on the upper surface of the impeller 2; Gasket 4; compression bolt 5; weight screw 6 and shroud 7.

[0024] The central shaft hole of the impeller 2 is matched with the rotor 1, wherein the central shaft hole of the impeller 2 is aligned with the rotor shaft, the impeller 2 is installed in the direction of the rotor 1, and then the impeller 2 is installed and fixed on the rotor 1 through the key 8. The upper end surface of the impeller 2 is recessed downward along the diameter direction to form a first notch 20 that divides the upper end surface of the impeller 2 into two parts, and a number of counterweight screw holes extending in the vertical direction are formed at even intervals on the two parts twenty one. The snap spring 3 includes a disc-shaped main body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com