Anti-corrosion rectangular corrugated expansion joint

A corrugated pipe, corrosion-resistant technology, applied in expansion compensation devices for pipelines, pipe components, pipeline protection, etc., can solve the problems of shortening the service life of compensators, increasing costs, and easy cracking of welds, and achieves improved The effect of using performance, improving service life and simplifying production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

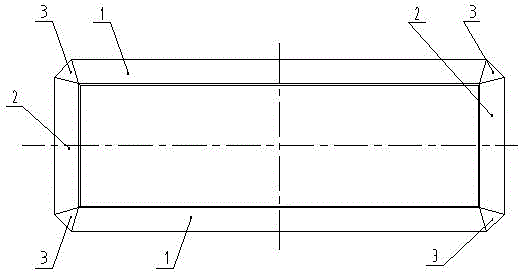

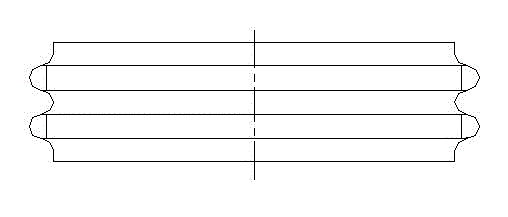

[0017] The corrosion-resistant rectangular bellows compensator shown in the accompanying drawings includes straight-line bellows I1, straight-line bellows II2, and straight-line bellows III3 with the same axial section shape. Tube II2 and linear corrugated tube III3 are cut from the same linear corrugated tube; linear corrugated tube I1 and linear corrugated tube II2 are composed of corrugated tubes and straight edges at both ends; linear corrugated tube I1 and linear corrugated tube Pipe II2 is provided with oblique cuts along the axial direction, two sets of relatively parallel linear bellows I1 and linear bellows II2 form a rectangle, and the straight edges at both ends are sealed together to form a rectangular interface, and the bellows section forms a triangular gap ; The linear bellows III3 is provided with oblique cuts along the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com