Filter element replacing device and method and fresh air fan

A new fan and filter element technology, applied in the field of filter element replacement devices, can solve the problems of unfavorable conventional installation of filter element replacement devices, lack of hidden storage of filter elements, lack of positioning accuracy and smoothness, etc., and achieve the goal of reducing the number of manual replacement and cleaning of filter elements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

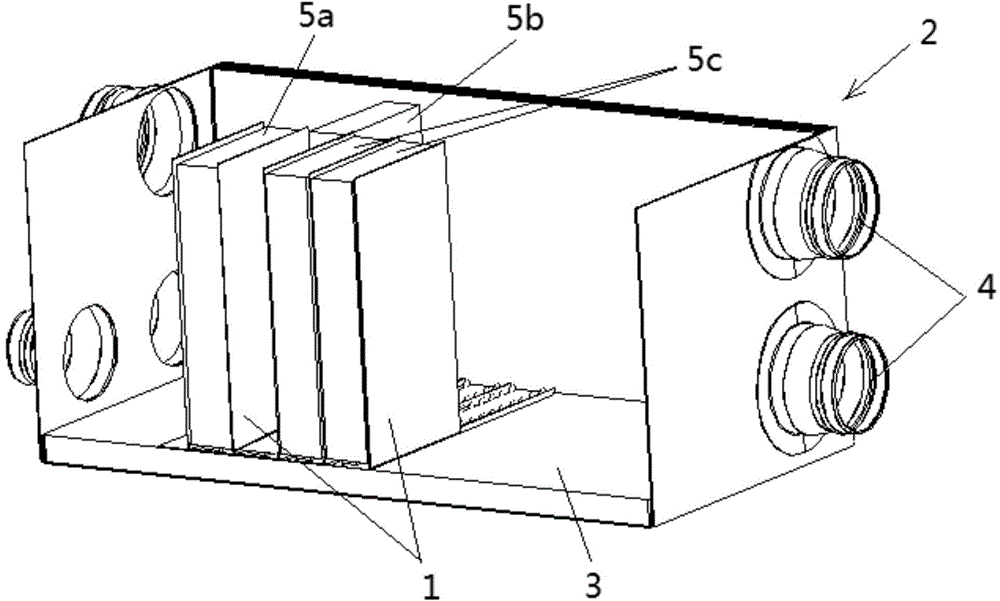

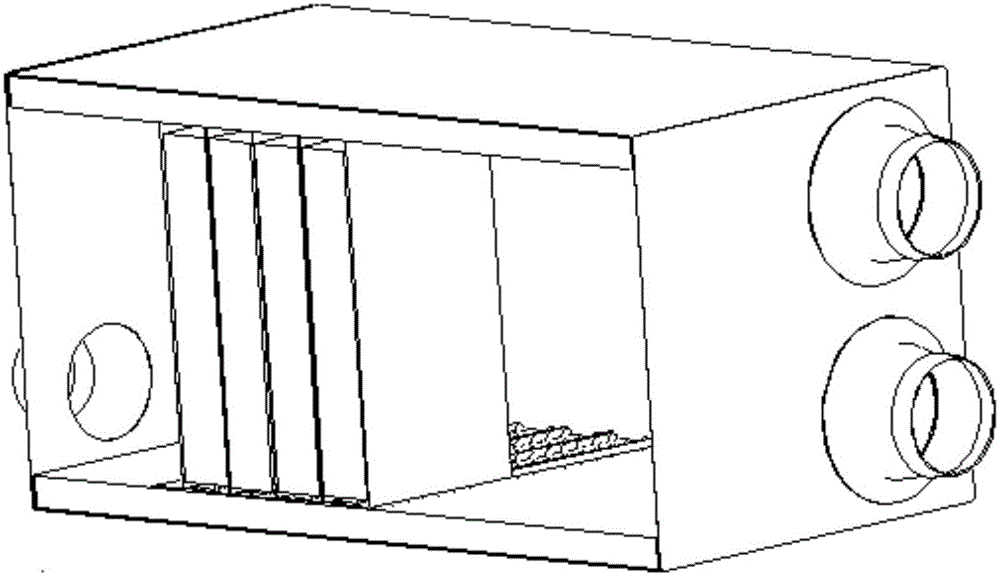

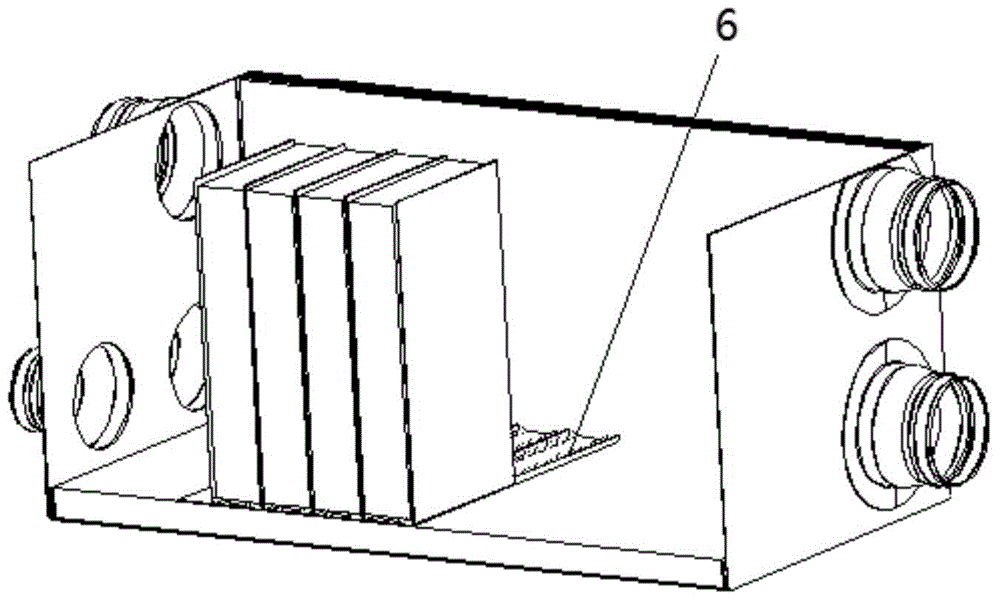

[0039] Such as figure 1 As shown, it is a schematic structural diagram of an embodiment of the filter element replacement device of the present invention. In this embodiment, the filter element replacement device mainly includes two mechanisms, namely a filter element storage mechanism and a power supply mechanism. Wherein, the filter element storage mechanism can accommodate at least two filter elements, providing a storage area for the new filter element before replacement and the old filter element after replacement. From figure 1 As can be seen in the figure, the filter element storage mechanism includes a plurality of partitions 1 whose size is not smaller than the filter element. Here it is required that the size of the separator should not be smaller than the filter element, so that the separator can completel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com