Full-automatic blast hole setting-out method for tunnel smooth surface blasting

A smooth blasting, fully automatic technology, applied in the field of blasting, can solve the problems affecting the tunnel process cycle, difficult to control tunnel over-under-digging, and workers' random drilling, so as to reduce the amount of over-excavation and reduce the tunnel operation cycle. Time, the effect of controlling the quality of smooth blasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

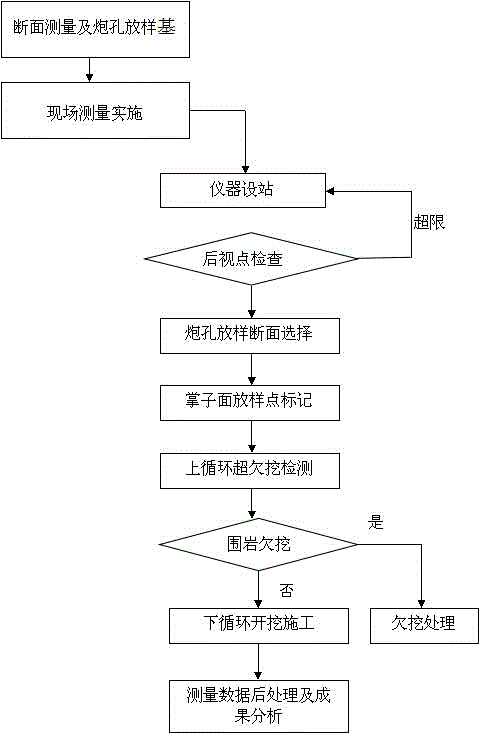

[0017] This embodiment is a fully automatic blasting hole stakeout method for tunnel smooth blasting, which is characterized in that the method includes the following steps:

[0018] Step 1: Selection of equipment and supporting software;

[0019] The selected instruments and equipment mainly include: the selection of a total station capable of full-automatic laser-free prism-free measurement system, supporting cross-section setting out and blasting hole setting out software, reflective sheets, tripods, and single prism groups;

[0020] Step 2: Data entry;

[0021] First, create a new job for this tunnel in the software, and then enter the tunnel section and tunnel line data, namely horizontal curves and vertical curves. When entering section data, you can use the direct import method of CAD drawings. When entering, you must pay attention to the selection of baselines and The relationship between the baseline and the tunnel line is finally selected according to the blast hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com