Test device and test method for crack evolution and seepage characteristic of gas-containing shale

A fracture evolution and characteristic testing technology, applied in the direction of measuring device, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problem of not being able to represent the overall deformation of the sample, gas leakage, and inability to reflect the flow rate of gas-bearing shale Changes and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

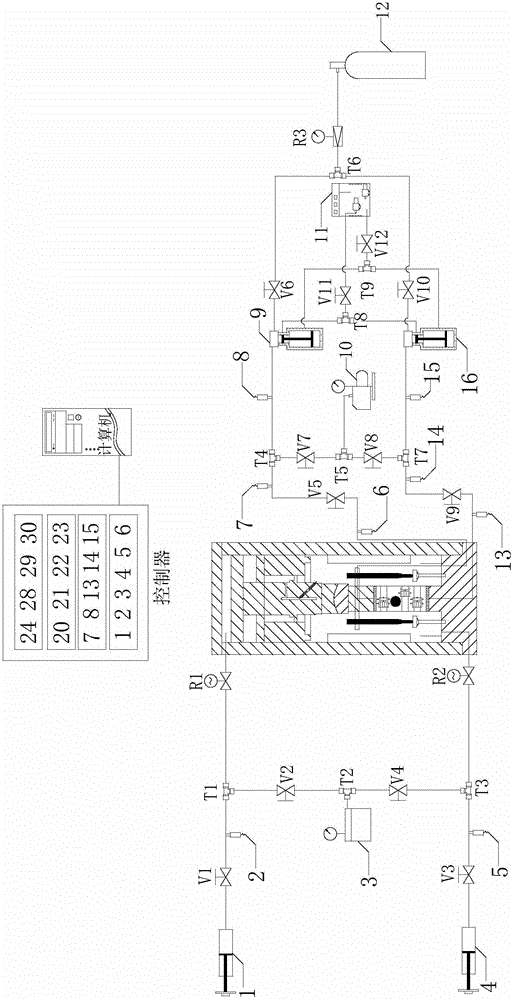

[0090] Such as figure 1 As shown, the gas-bearing shale fracture evolution and seepage characteristics testing device of the present invention includes a triaxial pressure chamber, a bias loading system, a hydrostatic pressure loading system, an upper fluid system, a lower fluid system, a vacuum system, a constant temperature system and a data control system. Acquisition System;

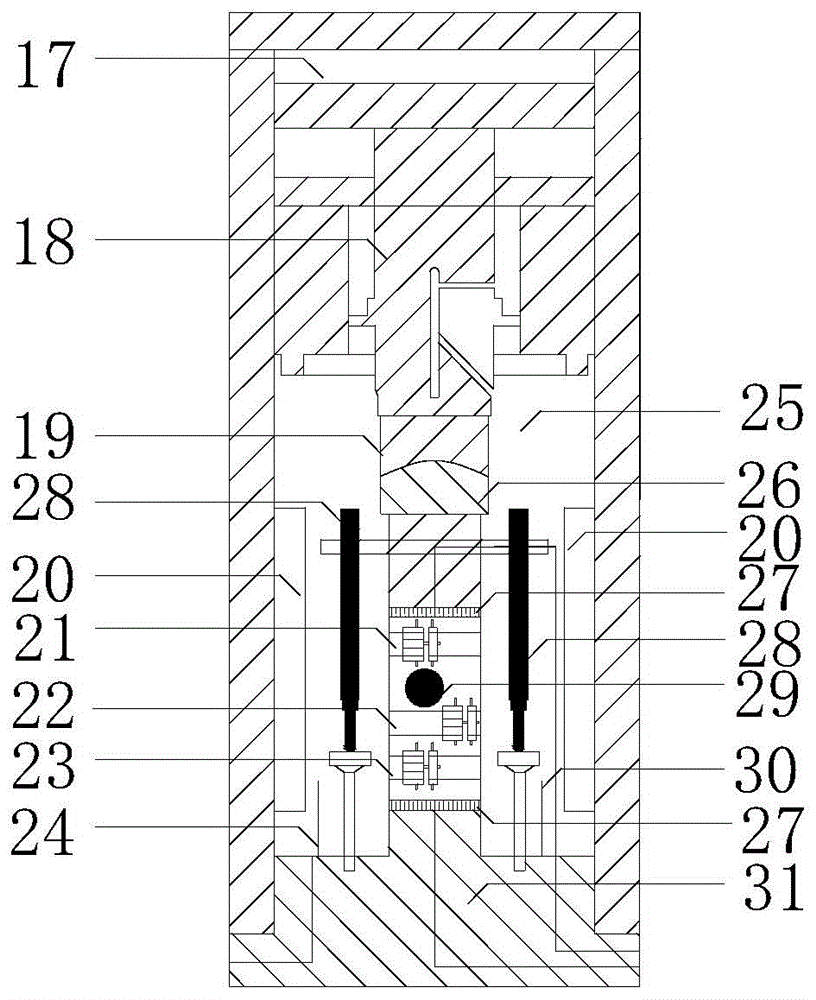

[0091] Such as figure 2 As shown, the triaxial pressure chamber includes an axial pressure chamber 17, a confining pressure chamber 25, a self-balancing piston 18, a ball head 19, an axial displacement sensor 28, an upper circumferential displacement sensor 21, a middle circumferential displacement sensor 22, and a lower circumferential displacement sensor. A displacement sensor 23, a porous gasket 27, an upper pressure head 26, a lower pressure platform 31 and a sample heating device. The axial pressure chamber 17 is set above the confining pressure chamber 25, and is connected by a self-balancin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com