A 90-degree gluing device for tabs of lithium batteries

A glue sticking device, lithium battery technology, applied in the direction of battery assembly machine, secondary battery manufacturing, battery pack parts, etc., can solve the problems of no good solution, relatively high personnel requirements, high labor cost, etc., to achieve filling Effects of vacancies, labor rate reduction, and productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] A 90-degree gluing device for tabs of a lithium battery according to the present invention will be described in detail below with reference to the accompanying drawings.

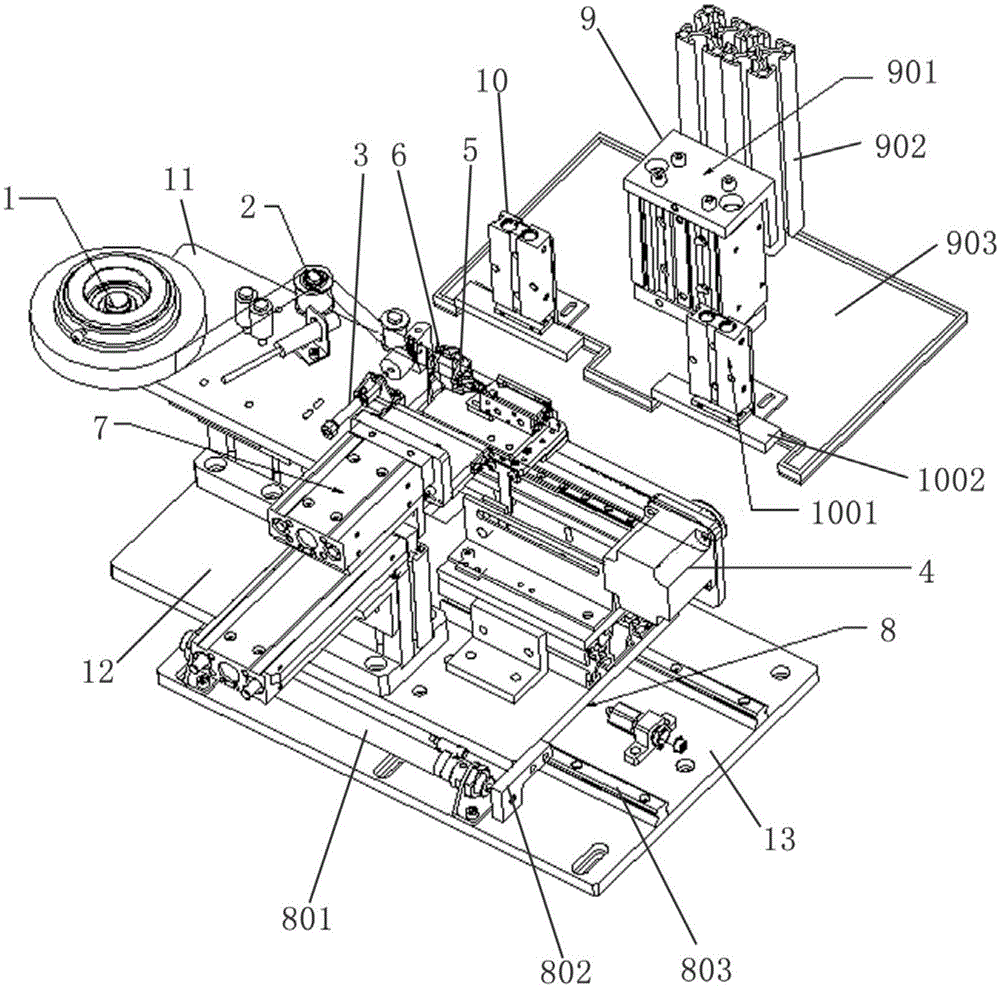

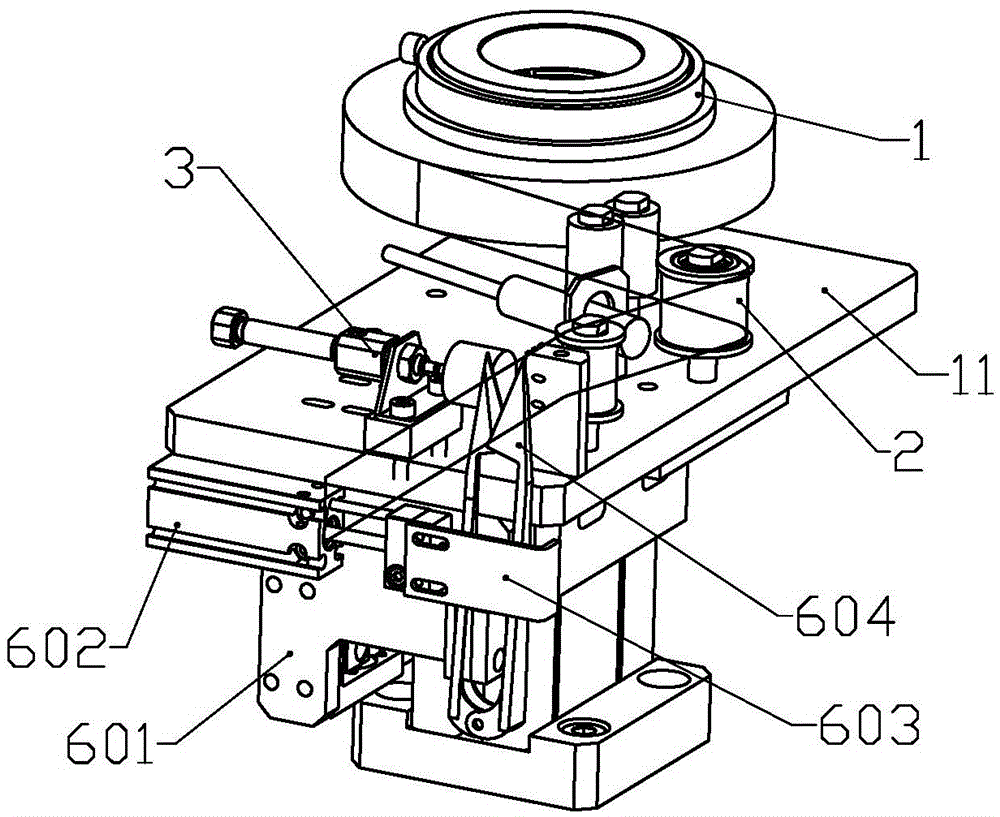

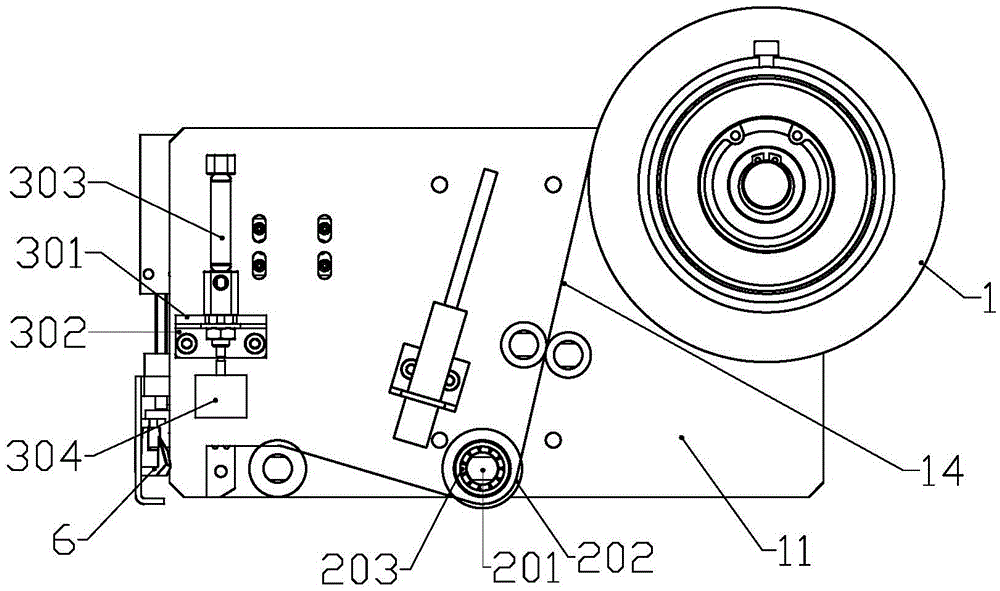

[0037]A 90-degree gluing device for lithium battery tabs according to the present invention has a structure comprising a tape fixing mechanism 1, a tape guiding mechanism 2, a glue pressing mechanism 3, a glue pulling driving mechanism 4, a glue clamping mechanism 5, a cutting mechanism 6, a tape Rolling mechanism 7, position moving mechanism 8, battery pressing mechanism 9 and tape beating mechanism 10; described tape fixing mechanism 1, tape guide mechanism 2, glue pressing mechanism 3 and shearing mechanism 6 are respectively arranged on tape fixing plate 11 Above, the tape fixing mechanism 1, the tape guiding mechanism 2, the glue pressing mechanism 3 and the shearing mechanism 6 are sequentially arranged along the tape fixing plate 11 from left to right; the glue pulling driving mechanism 4, the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com