Electrical heater capable of realizing heat conduction and infrared radiation at the same time

A technology of infrared radiation and electric heater, applied in the direction of ohmic resistance heating parts, heating element shape, etc., can solve the problems of easy burnout of resistance wire and low efficiency of heater.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

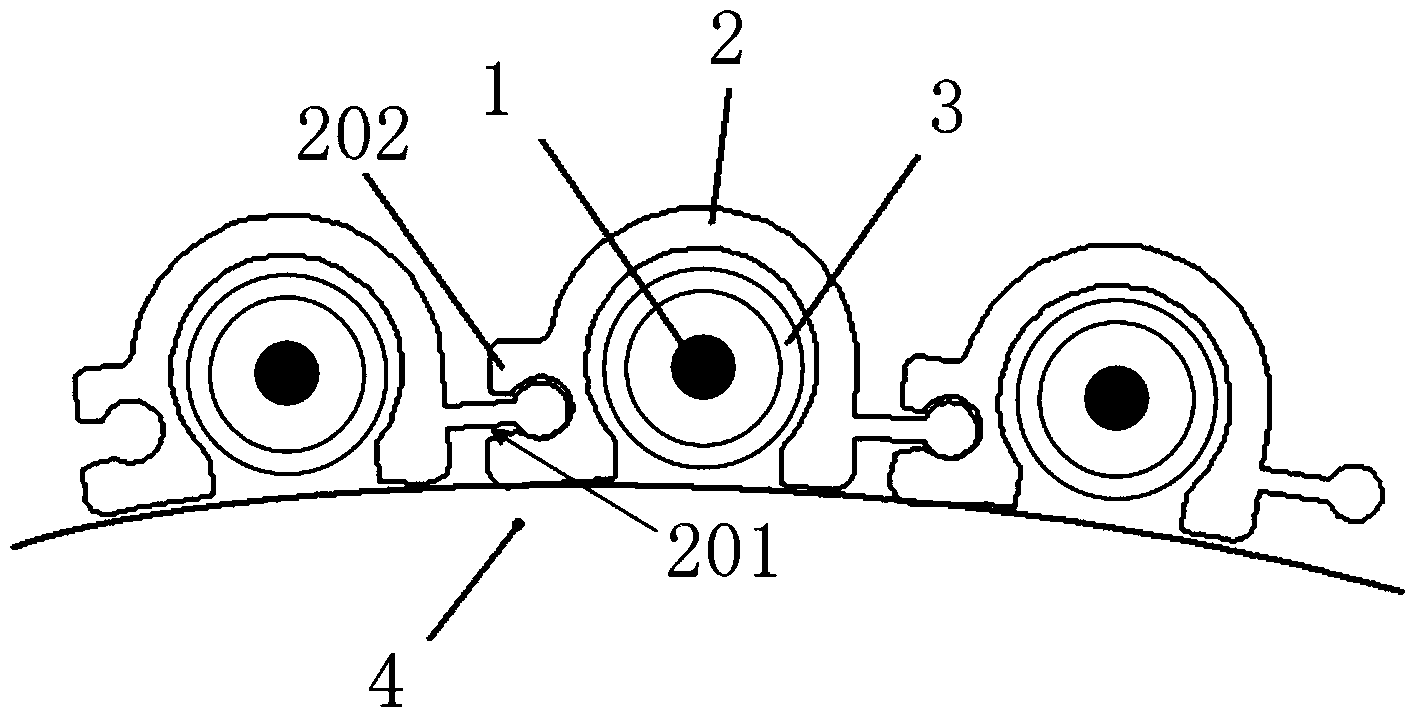

[0025] Such as figure 1 as shown in figure 1 is the first embodiment of the present invention, such as figure 1 As shown, the electric heater includes a resistance wire 1 for providing a heat source. The resistance wire 1 is fixed in the quartz tube 3 . When the resistance wire 1 is energized, 95% of the generated near-infrared light and visible light are converted into far-infrared rays by the quartz tube 3 . The quartz tube 3 is fixed by the heat-conducting metal 2 , and the quartz tube 3 is closely attached to the surface of the heated object 4 . At the same time, the heat-conducting metal 2 is also in close contact with the surface of the object 4 to be heated. The advantage of this design is that the heat transferred other than the far-infrared radiation can realize heat conduction through the close contact between the heat-conducting metal 2 and the object to be heated 4 . Compared with the prior art, the heat transfer efficiency is further increased.

[0026] Anot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com