PCB manufacturing method and PCB

A manufacturing method and printed circuit board technology are applied in the direction of electrical connection formation of printed components, electrical connection of printed components, printed circuit components, etc., which can solve problems such as the inability to meet the requirements of wiring density, and achieve increased wiring space, The effect of enhanced routing capability and increased pad spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

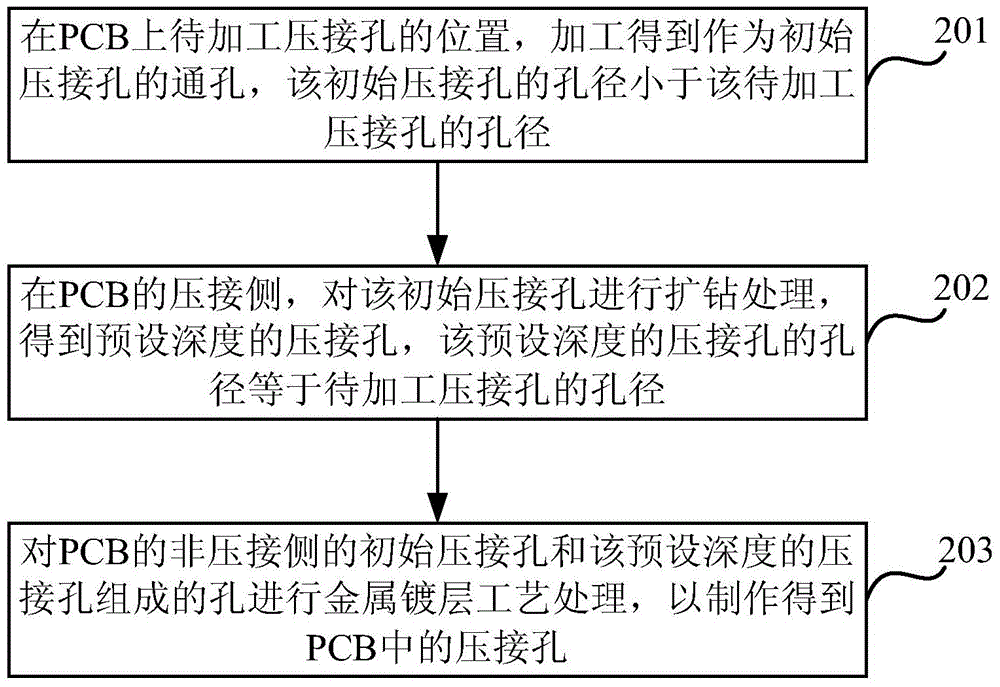

[0028] Aiming at the problems existing in the prior art, the embodiment of the present invention provides a PCB manufacturing method, which is used to make crimping holes in the PCB, such as figure 2 As shown, the method includes the following steps:

[0029] Step 201 , at the position of the crimping hole to be processed on the PCB, a through hole as an initial crimping hole is processed, and the diameter of the initial crimping hole is smaller than that of the crimping hole to be processed.

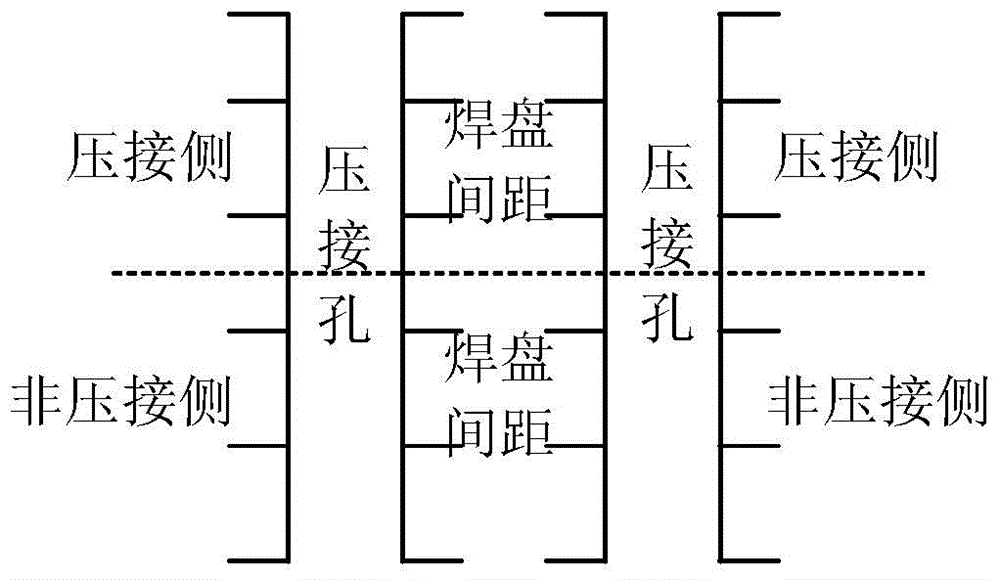

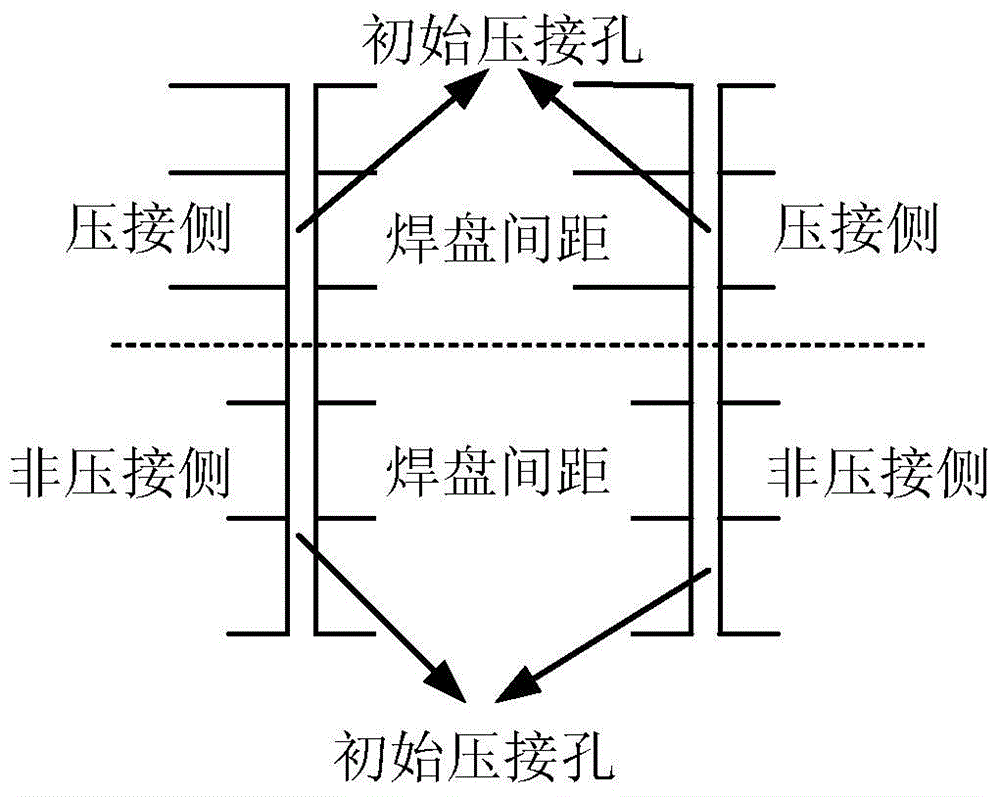

[0030] Wherein, the crimping hole to be processed is the crimping hole that needs to be processed in the prior art. The crimping hole of PCB is divided into crimping side and non-crimping side, such as Figure 3A-Figure 3D As shown, it is a schematic diagram of the processed through hole as the initial crimping hole. The diameter of the initial crimping hole on the crimping side is consistent with the diameter of the initial crimping hole on the non-crimping side, and the initial crim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com