Bamboo carding machine

The technology of a bamboo silk carding machine and a carding roller is applied in the directions of mechanical equipment, mechanical processing of plant materials, etc., which can solve the problems of irregular arrangement of bamboo silk, reduce the strength and toughness of reconstituted bamboo, and achieve the effect of simple operation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

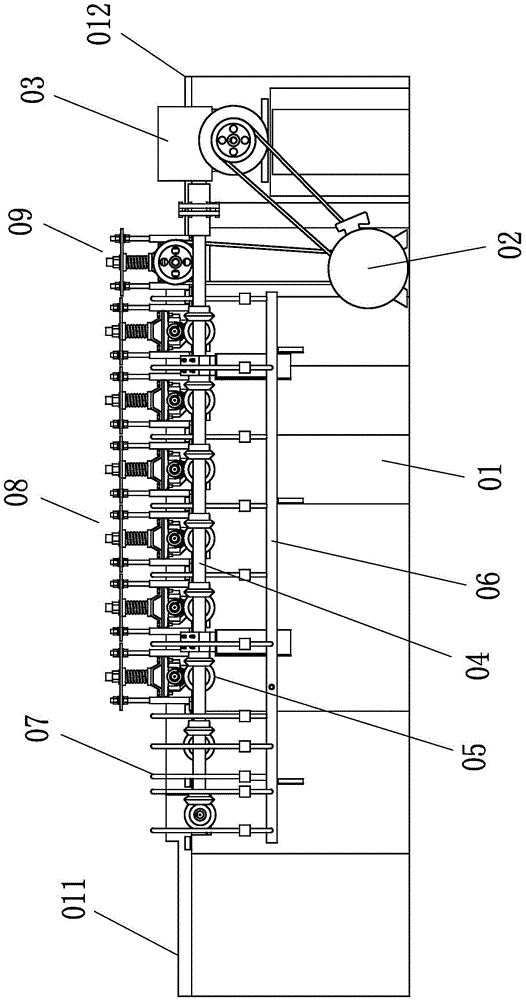

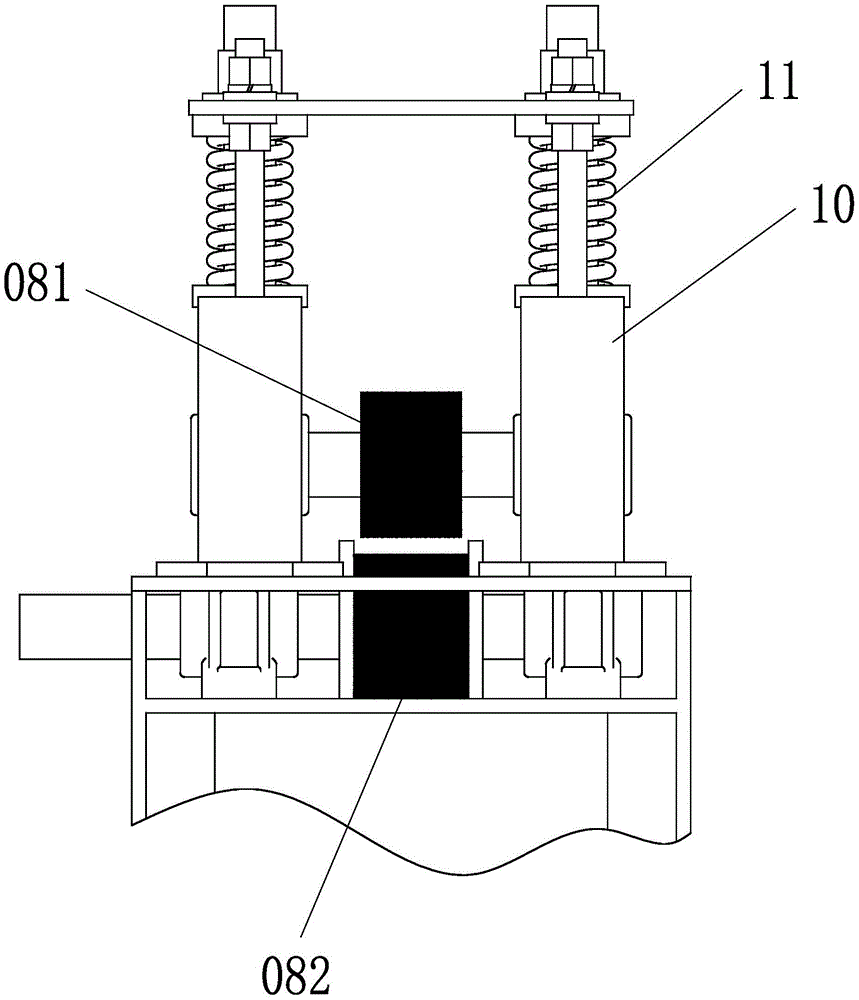

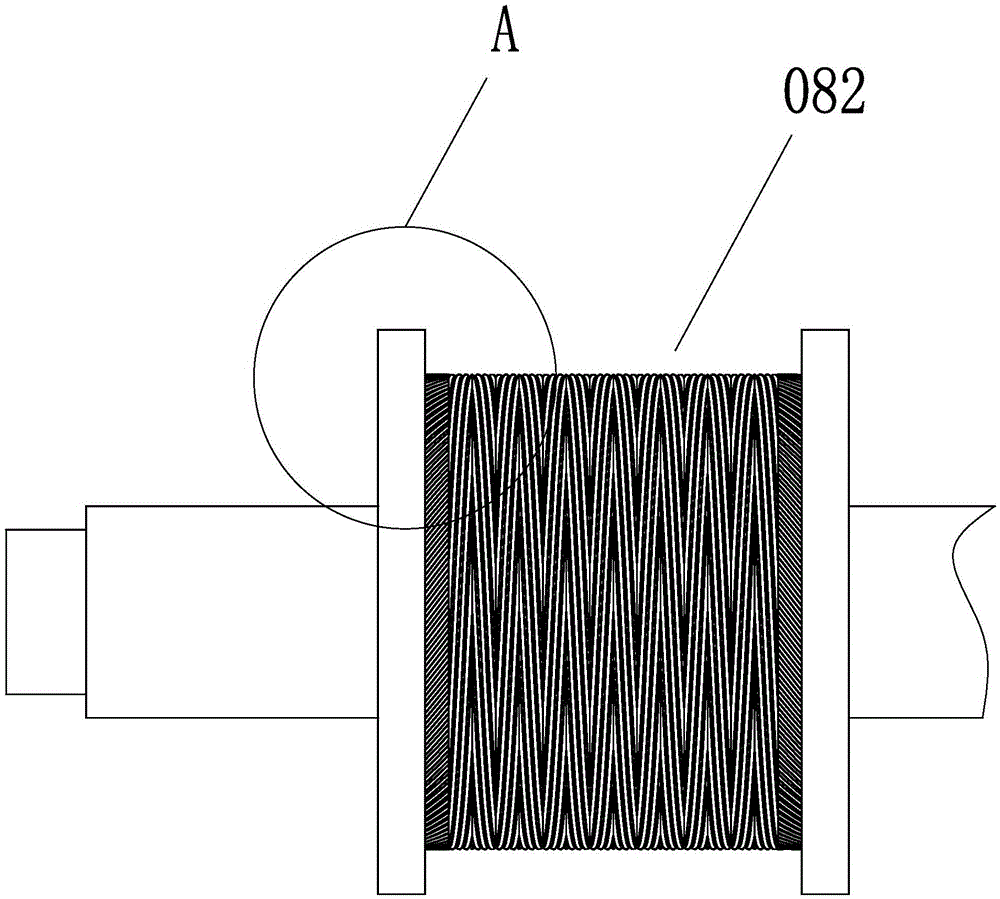

[0028] Embodiment 1: as figure 1 , 2 , 3, 4, and 5, a kind of bamboo silk carding machine, including frame 01 and motor 02, one end of the horizontal direction of the frame is the input end 011, the other end is the output end 012, the input end and the output end of the frame A steam delivery pipe 06 is horizontally arranged between them, and several steam spraying pipes 07 arranged at intervals for heating the bamboo filaments are connected to the steam delivery pipe. A conveying mechanism 08 and a carding mechanism 09 are arranged sequentially between the input end and the output end of the frame. An output shaft and a motor 02 for driving the output shaft to rotate are installed on the frame 01. Both the conveying mechanism 08 and the carding mechanism 09 pass through the inclined The gear 05 is connected with the output shaft, and the transmission ratio of the helical gear increases sequentially along the feeding direction. The carding mechanism comprises a carding roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com