Color spinning cotton sliver proofing device

A technology of cotton sliver and color spinning, which is applied in the field of proofing equipment for color spinning sliver, which can solve the problems of poor quality of finished sliver, waste of manual work time, and inability to remove dust from various sliver blanks, so as to improve quality , Improve convenience and reduce operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

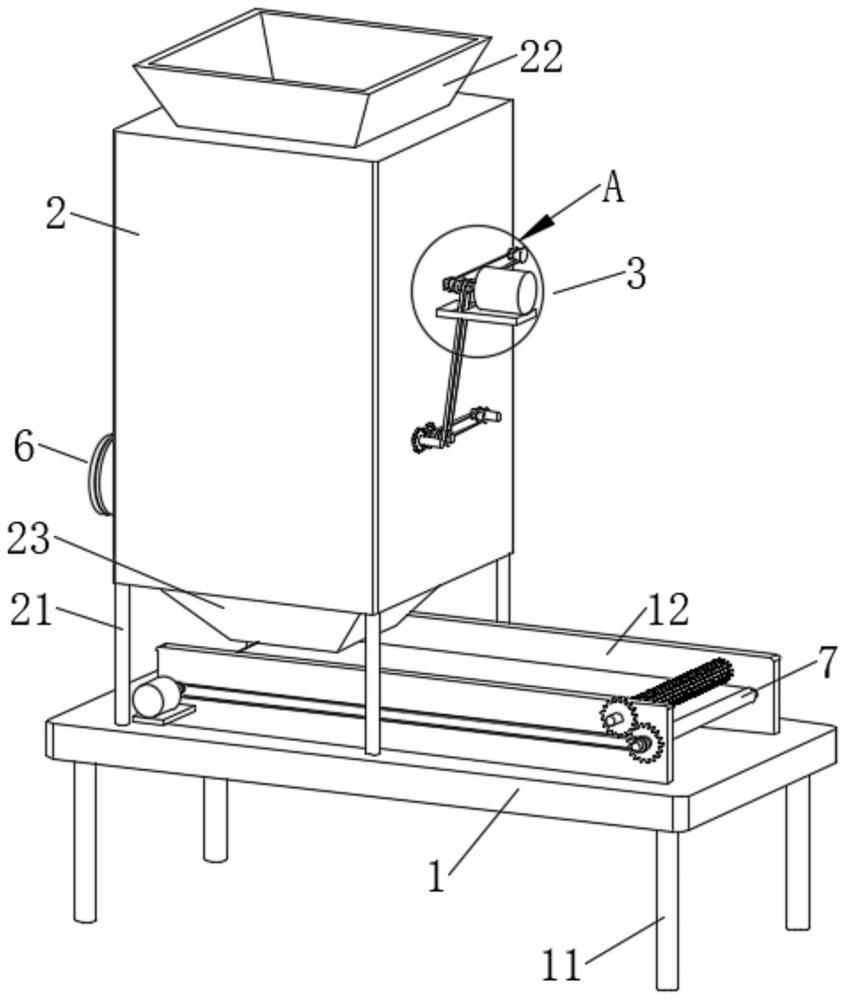

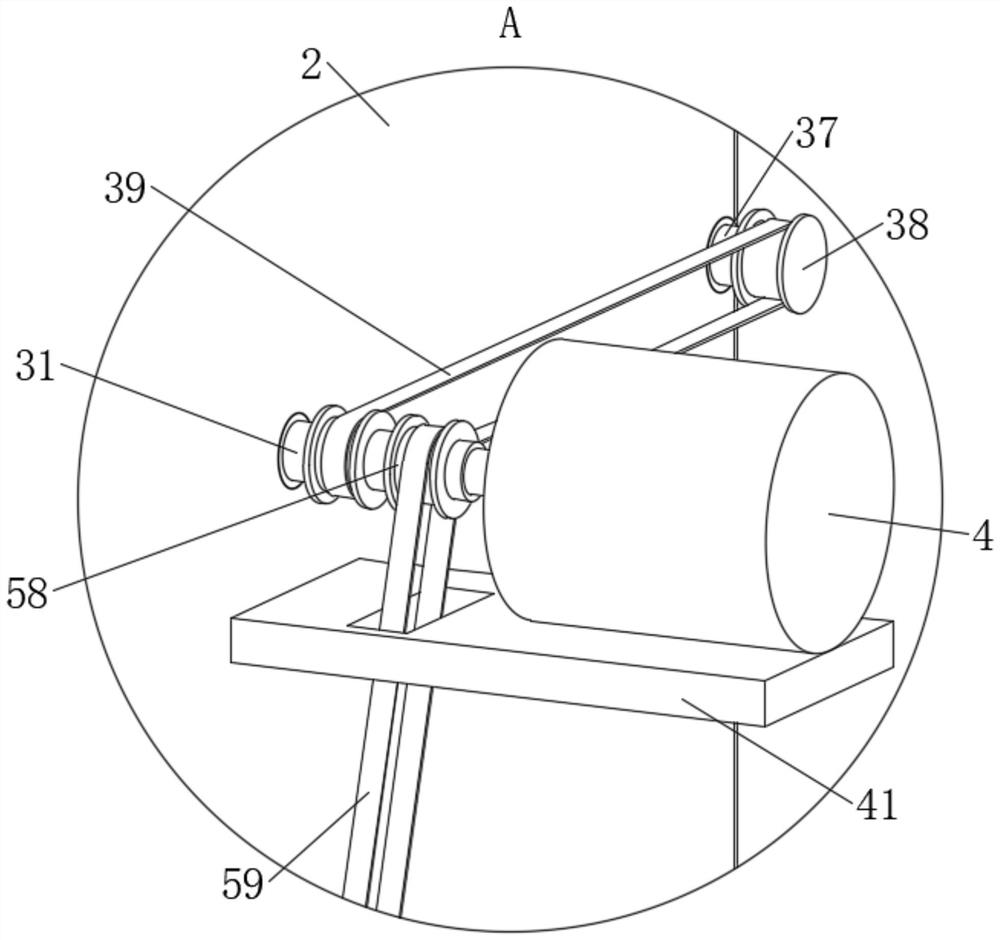

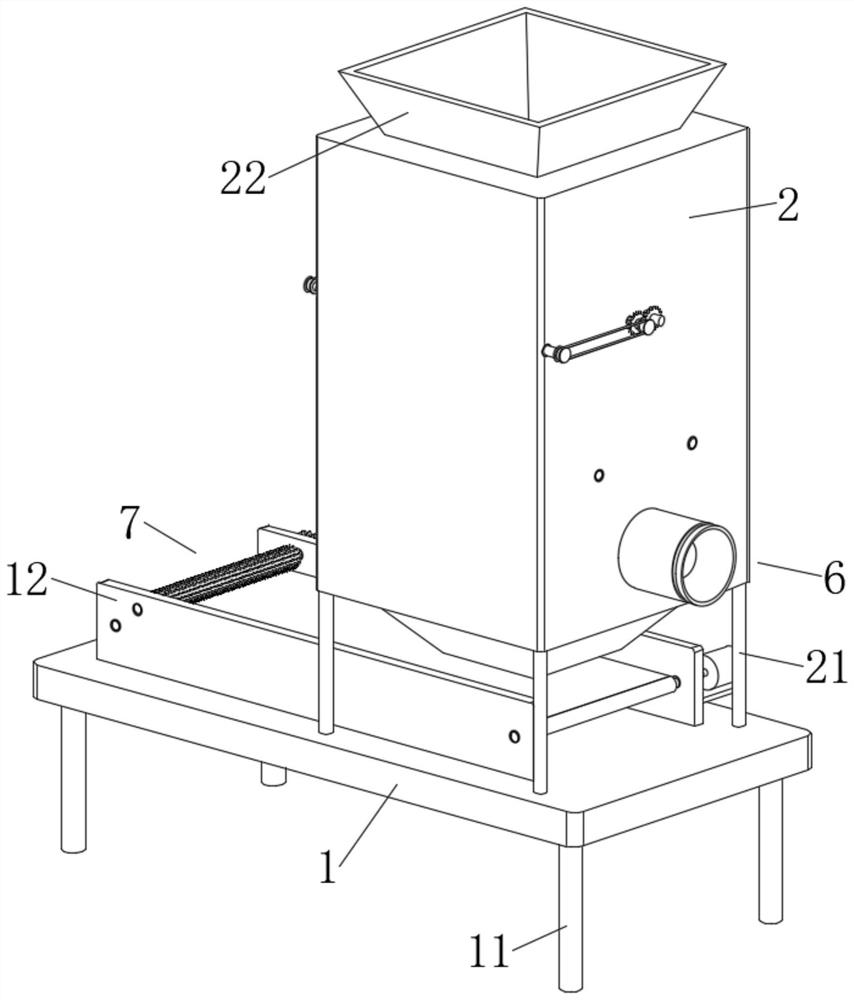

[0032] Example: such as Figure 1-9 As shown, the present invention provides a kind of proofing equipment for color spinning cotton slivers, comprising a preparation table 1, the upper surface of the preparation table 1 is symmetrically fixed with a side plate 12, and the side of the preparation table 1 close to the side plate 12 is fixed with a preparation box 2. A feed hopper 22 is fixedly installed on the side of the preparation box 2 far away from the preparation table 1. Through the feed hopper 22, the sliver stock can be conveniently added to the inside of the preparation box 2, and the preparation box 2 is far away from the feed hopper 22. A discharge hopper 23 is fixedly installed on one side, and the discharge hopper 23 can realize the discharging of the sliver stock conveniently. The inner wall of the preparation box 2 is symmetrically provided with a circular groove 24, and the inside of the preparation box 2 is respectively provided with a mixing mechanism 3 and a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com