A kind of zipper injection molding machine and zipper injection molding method

A technology for injection molding machines and zippers, which is applied in the direction of coating, etc., can solve problems such as deviations in the control process, unguaranteed quality, uneven chain belts, etc., and achieve the effects of small deformation range, small error, and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below through specific embodiments.

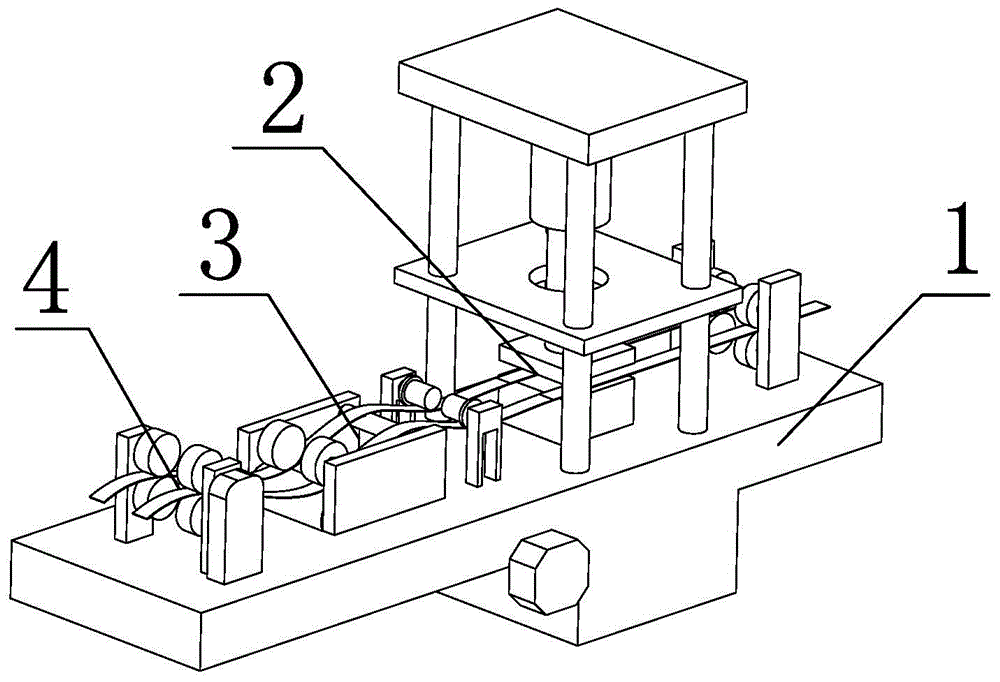

[0025] refer to Figure 1 to Figure 3 As shown, a zipper injection molding machine includes a workbench 1, an injection molding machine 2, a transmission device 3 and a belt loosening device 4;

[0026] The workbench 1 is arranged along the horizontal direction;

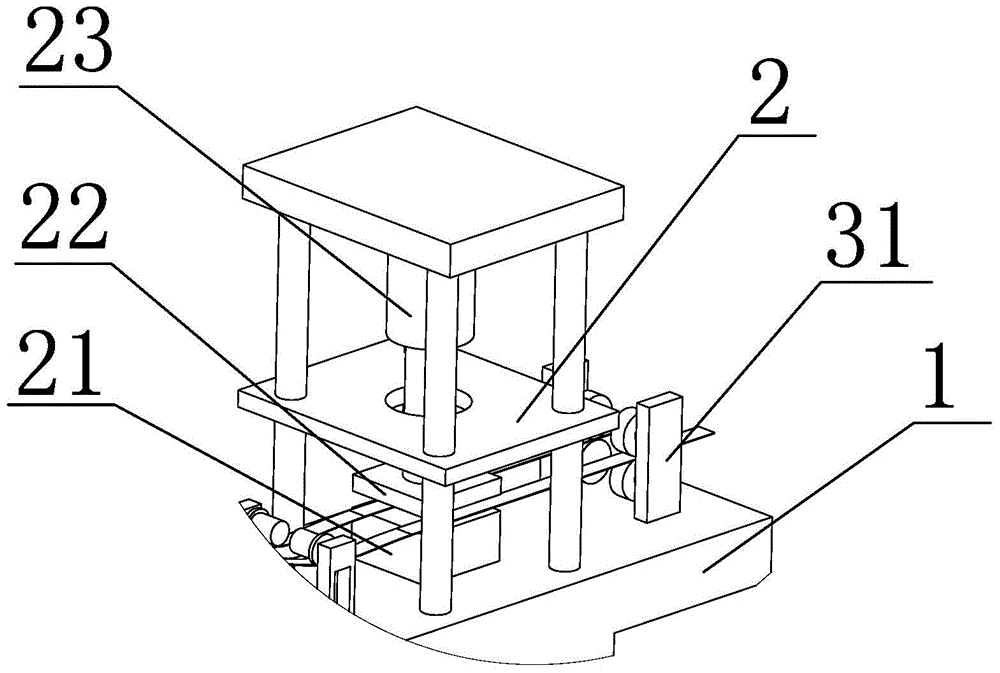

[0027] The injection molding host 2 includes a lower mold 21, an upper mold 22, and a host driving mechanism 23. The lower mold 21 is installed on the workbench 1, the upper mold 22 is correspondingly arranged above the lower mold 21, and the host driving mechanism 23 is connected to and driven by the upper mold 22. It moves up and down;

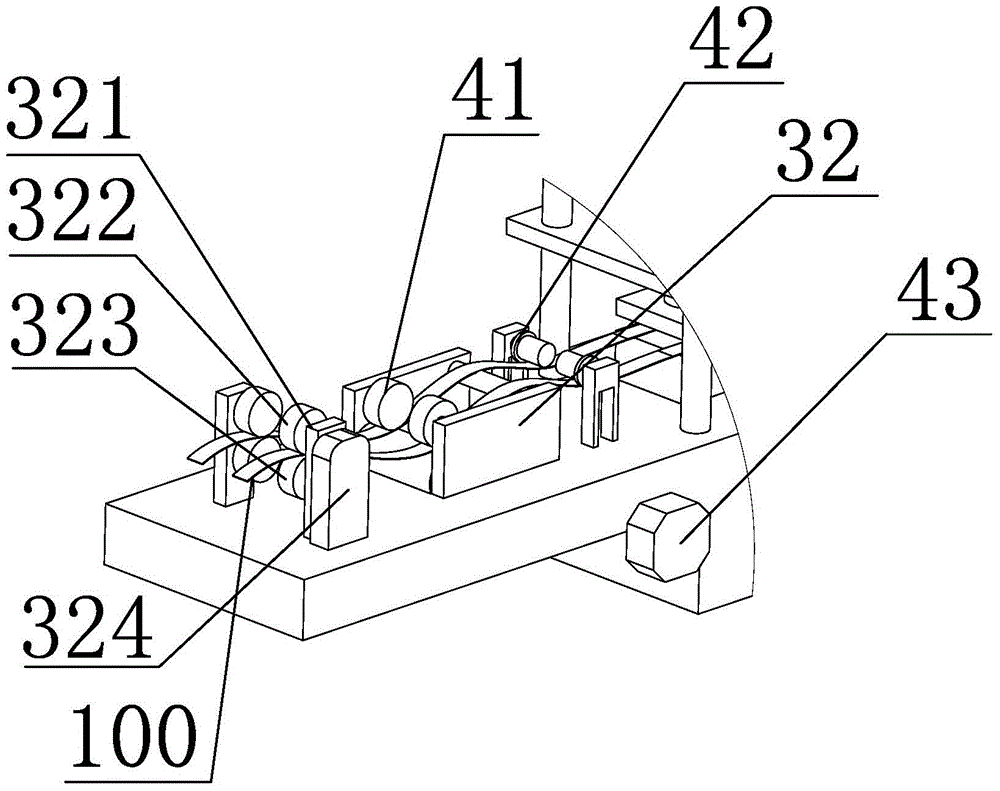

[0028] The conveying device 3 includes a belt feeder 31 and a belt puller 32 arranged on both sides of the injection molding main machine 2. The belt puller 32 includes a mounting seat 321, a driving wheel 322, a driven wheel 323 and a transmission drive mechanism 324. The mounting seat 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com