Transmission double station punching machine

A dual-station, punching machine technology, applied in the field of machinery, can solve the problems of poor rigidity of the worktable, high cost, complex structure, etc., and achieve the effect of improving production efficiency, low center of gravity, and realizing stroke enlargement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be further described in detail below.

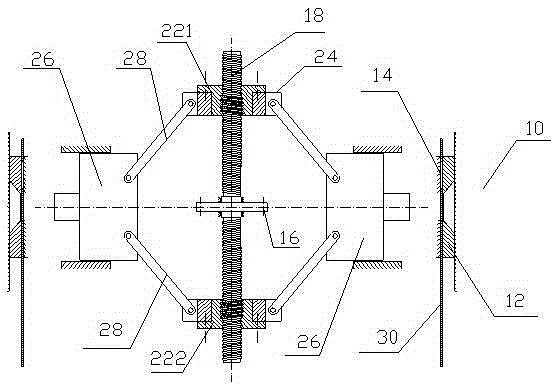

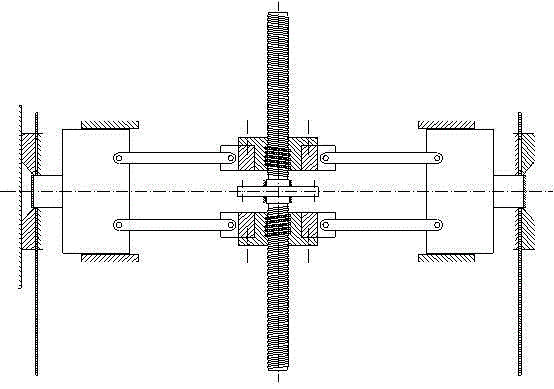

[0014] Such as figure 1 and figure 2 As shown, a transmission-type double-station punching machine of the present invention includes a horizontal symmetrical layout machine tool (not shown) and two punching stations 10, and the punching station 10 in this embodiment is for punching sheet-shaped materials. Structure, the stamping station 10 is provided with a mold 12, and a guide groove 14 for guiding the workpiece to be processed is provided between the two punch sliders 26 and the mold 12. Of course, the present invention can also be applied to stamping materials of other structures, and these are all improvements that can be easily imagined by those skilled in the art based on the content of the present invention. The machine tool is provided with a power input element 16 and a driving device (not shown) for driving the power input element 16 to rotate. The driving device ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com