Toughened glass fender for cars

A technology of tempered glass and mudguard, which is applied to vehicle parts, superstructure, subassembly of superstructure, etc., can solve problems such as increased cost and shortened service life of rubber mudguards, and achieves convenient disassembly and maintenance, and strong applicability. , the effect of low scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

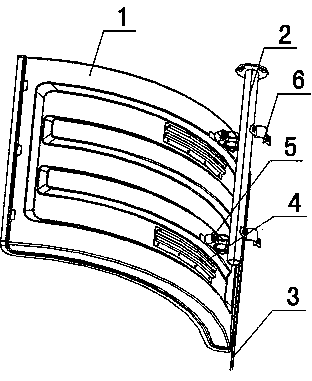

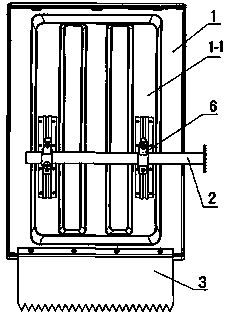

[0009] Depend on figure 1 , figure 2 Known, a kind of tempered glass fender for vehicle is made up of fender 1, fender support rod 2, fender cover 3, fender guide rail 4, fender cover fixing seat 5 and fixing seat pressing piece 6, The mudguard is a tempered glass with a radian, and two grooves 1-1 are arranged on the arc surface, and the mudguard guide rail 4 is fixed in the groove 1-1 through the mudguard fixing seat 5 and the fixing seat pressing piece 6. 1, it is characterized in that: the fender cover support bar 2 on the fender cover fixing seat 5 is embedded into the fender cover guide rail 4 from the open end of the fender cover guide rail 4, and the fender cover 3 is fixed on the fender cover guide rail 4 by bolts. The lower end of mudguard cover 1. The fender cover support bar 2 is connected with two fender cover holders 5, and the fender cover holders 5 can move along the fender cover guide rail 4 for adjusting the relative position between the fender cover 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com