Method for extracting residual protein in edible vegetable oil

A technology for edible vegetable oil and edible oil, applied in the biological field, can solve problems such as unreported, and achieve the effects of wide applicability, low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

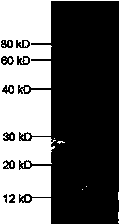

Image

Examples

Embodiment 1

[0034] (1) Add 36-44ml edible oil and 9-11ml extract to the centrifuge tube and mix well; the extract consists of 0.2% SDS, pH 7.5, 0.1 M Tris-HCl, 0.5 M NaCl, 10 mM DTT;

[0035] (2) Centrifuge the mixture of edible oil and extract obtained in step (1) with a centrifugal force of 8000-12000g for 4-6 min; (3) Take the mixture of edible oil and extract obtained in step (2) after centrifugation Add 2.5-3.5 ml 50% TCA to the lower aqueous phase, mix well, and place in ice bath for 15-25 min;

[0036] (4) Centrifuge the mixture of the lower aqueous phase and TCA obtained in step (3) with a centrifugal force of 8000-12000g for 8-12 min;

[0037] (5) Discard the supernatant of the mixture of the lower aqueous phase and TCA after centrifugation in step (4), add 1.5-2.5 ml of 80% cold acetone to wash the precipitate, and recover the precipitate;

[0038] (6) Centrifuge the precipitate washed with cold acetone obtained in step (5) with a centrifugal force of 10000-14000g for 4-6 min, ...

Embodiment 2

[0041] (1) Add 38-42ml edible oil and 9.5-10.5ml extract to the centrifuge tube and mix well; the extract consists of 0.2% SDS, pH 7.5, 0.1 M Tris-HCl, 0.5 M NaCl, 10 mM DTT;

[0042] (2) Centrifuge the mixture of edible oil and extract obtained in step (1) with a centrifugal force of 9000-11000g for 4.5-5.5min;

[0043] (3) Take the lower aqueous phase of the mixture of edible oil and extract after centrifugation in step (2), add 2.75-3.25 ml 50% TCA, mix well, and place in ice bath for 17.5-22.5 min;

[0044] (4) Centrifuge the mixture of the lower aqueous phase and TCA obtained in step (3) with a centrifugal force of 9000-11000g for 9-11 min;

[0045] (5) Discard the supernatant of the mixture of the lower aqueous phase and TCA after centrifugation in step (4), add 1.75-2.25 ml of 80% cold acetone to wash the precipitate, and recover the precipitate;

[0046] (6) Centrifuge the precipitate washed with cold acetone obtained in step (5) with a centrifugal force of 11000-1300...

Embodiment 3

[0049] (1) Add 36ml of a certain brand of pressed peanut oil and 9ml of extract to the centrifuge tube and mix well; the extract consists of 0.2% SDS, pH 7.5, 0.1 M Tris-HCl, 0.5 M NaCl, 10 mM DTT;

[0050] (2) Centrifuge the mixture of edible oil and extract obtained in step (1) with a centrifugal force of 8000g for 4 minutes;

[0051] (3) Take the lower aqueous phase of the mixture of edible oil and extract after centrifugation in step (2), add 2.5 ml 50% TCA, mix well, and place in ice bath for 15 minutes;

[0052] (4) Centrifuge the mixture of lower aqueous phase and TCA obtained in step (3) with a centrifugal force of 8000g for 8 min;

[0053] (5) Discard the supernatant of the mixture of the lower aqueous phase and TCA after centrifugation in step (4), add 1.5 ml of 80% cold acetone to wash the precipitate, and recover the precipitate;

[0054] (6) Centrifuge the precipitate washed with cold acetone obtained in step (5) with a centrifugal force of 10,000g for 4 minutes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com