Coating device and coating method

A coating device and coating technology, which are applied in sputtering coating, vacuum evaporation coating, ion implantation coating and other directions, can solve the problems of slow heating and cooling process, unsuitable for industrial production and application, affecting coating quality, etc., and achieve low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be further described below according to specific embodiments. The protection scope of the present invention is not limited to the following examples, which are listed for illustrative purposes only and do not limit the present invention in any way.

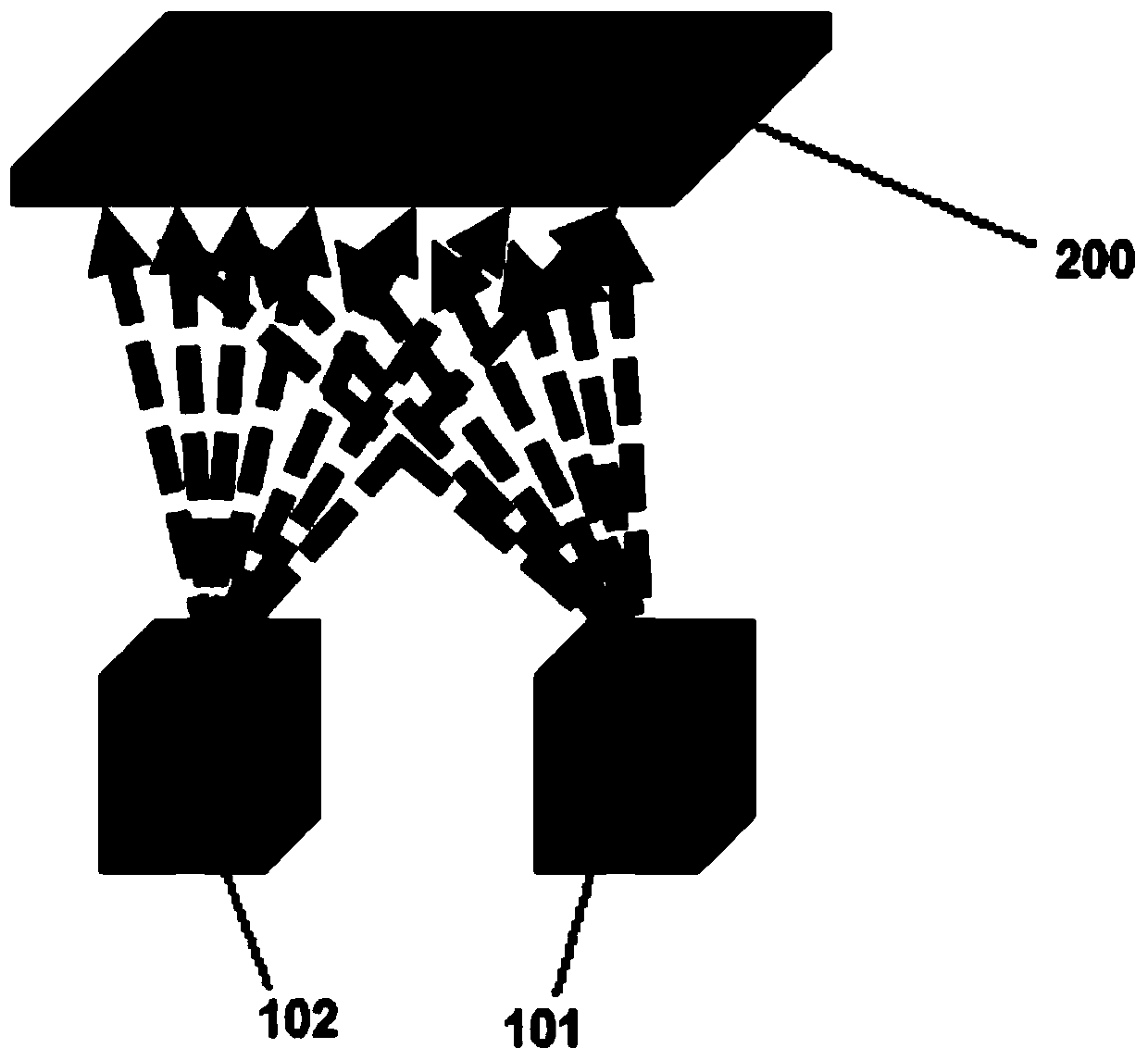

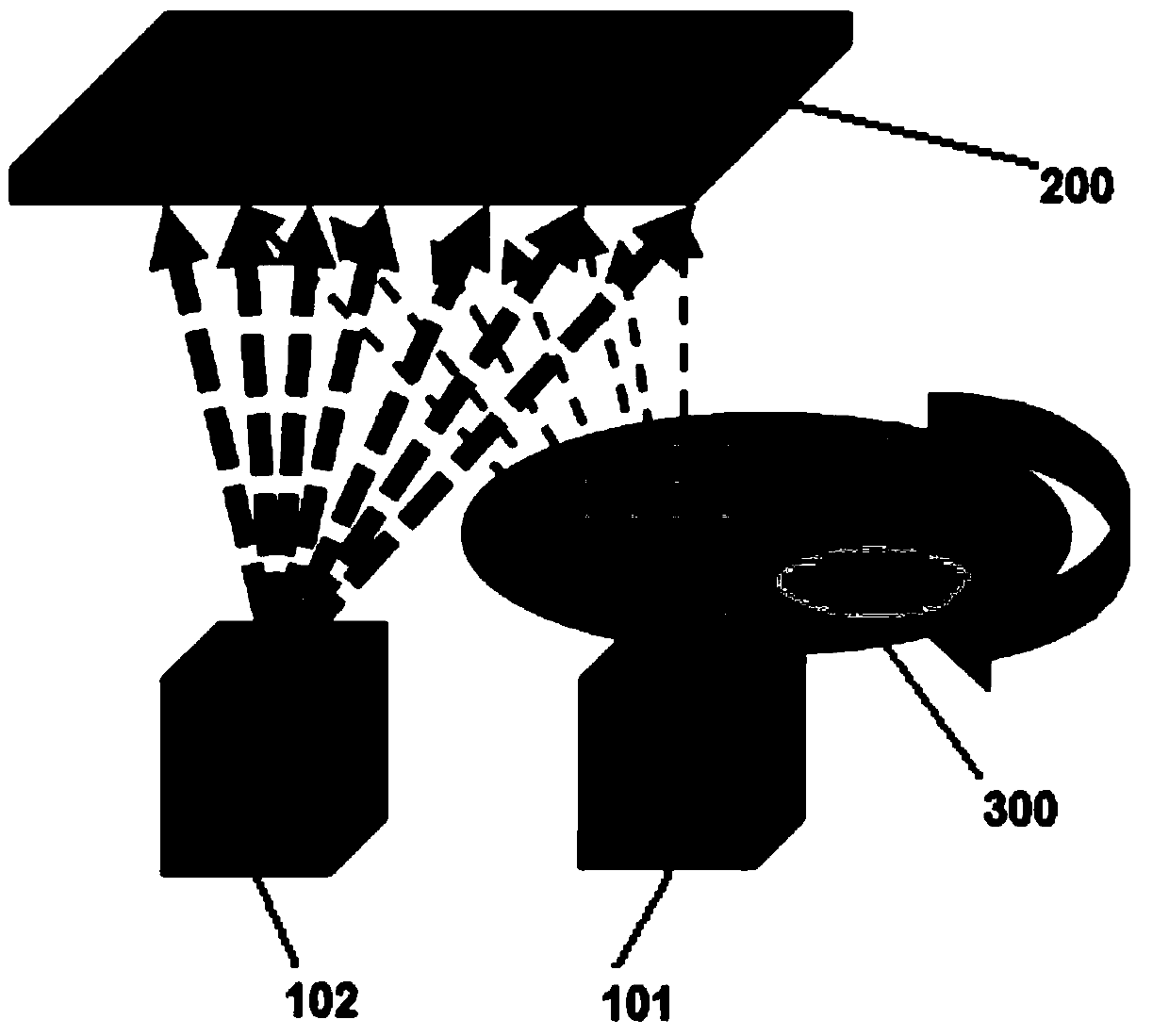

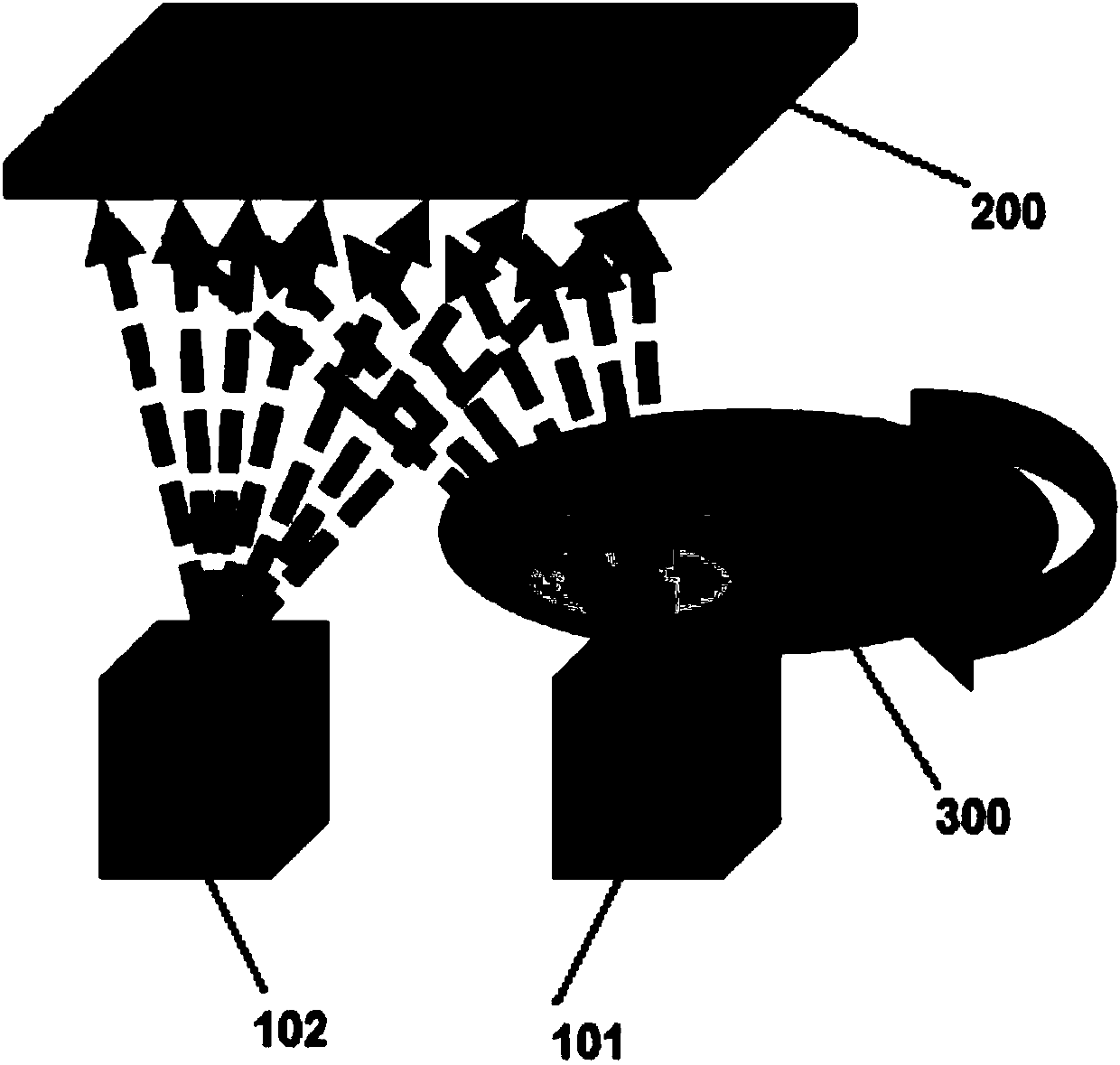

[0033] figure 2 and image 3 An embodiment of the coating device of the present invention is shown, as figure 2 and image 3 As shown, the coating device includes a first evaporation source 101, which is arranged under the substrate to be processed 200; a second evaporation source 102, which is arranged under the substrate 200 to be processed; and a first opening shutter 300, the first opening The hole shutter 300 is disposed between the first evaporation source 101 and the substrate 200 to be processed.

[0034] The film coating device of the present invention is usually installed in a film coating chamber, and maintains a vacuum environment during operation.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com