Internal and external supporting rod type cable-arch structure

A cable arch and rod type technology, which is applied in the field of inner and outer brace type cable arch structures, can solve the problems of chemical instability of the protective layer, PE chemical instability, structural safety hazards, etc., so as to improve the collapse resistance and prevent continuous collapse , The effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

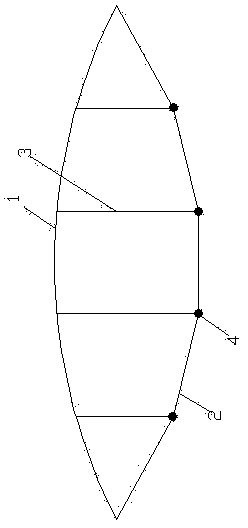

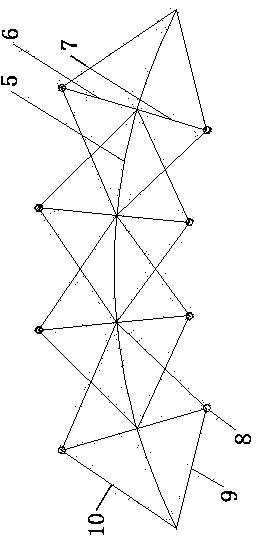

[0020] refer to image 3 , an inner and outer strut type cable-arch structure, comprising an upper string 5, the upper string 5 can also be an arch or a truss, on the upper string 5 along its length direction, several groups of string cables are arranged, and each group of string cables is connected to the upper string There are struts between the beams 5 , and the string cables and struts are in the same plane as the upper run beam 5 ; Each group of chord stay cables includes an upper stay cable 10 and a lower pull cable 9 arranged in a V shape on both sides of the upper string beam 5. The opening of the upper stay cable 10 is set downward, and the opening of the lower pull cable 9 is set upward. Both the front and rear free ends of the upper stay cable 10 and the lower stay cable 9 are respectively hinged with the upper run beam 5, and the hinge points on the same side coincide. Between the inflection point of the last stay cable 10 and the upper chord beam 5, there is an u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com