Adjustable hydraulic clutch release bearing assembly with inner ring rotation

A hydraulic clutch and release bearing technology, applied in clutches, fluid-driven clutches, non-mechanical drive clutches, etc., can solve the problems of short service life of hydraulic clutch release bearing assemblies, easy entry of rolling channels, etc., and improve dust-proof sealing performance. , reducing friction and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings of the description.

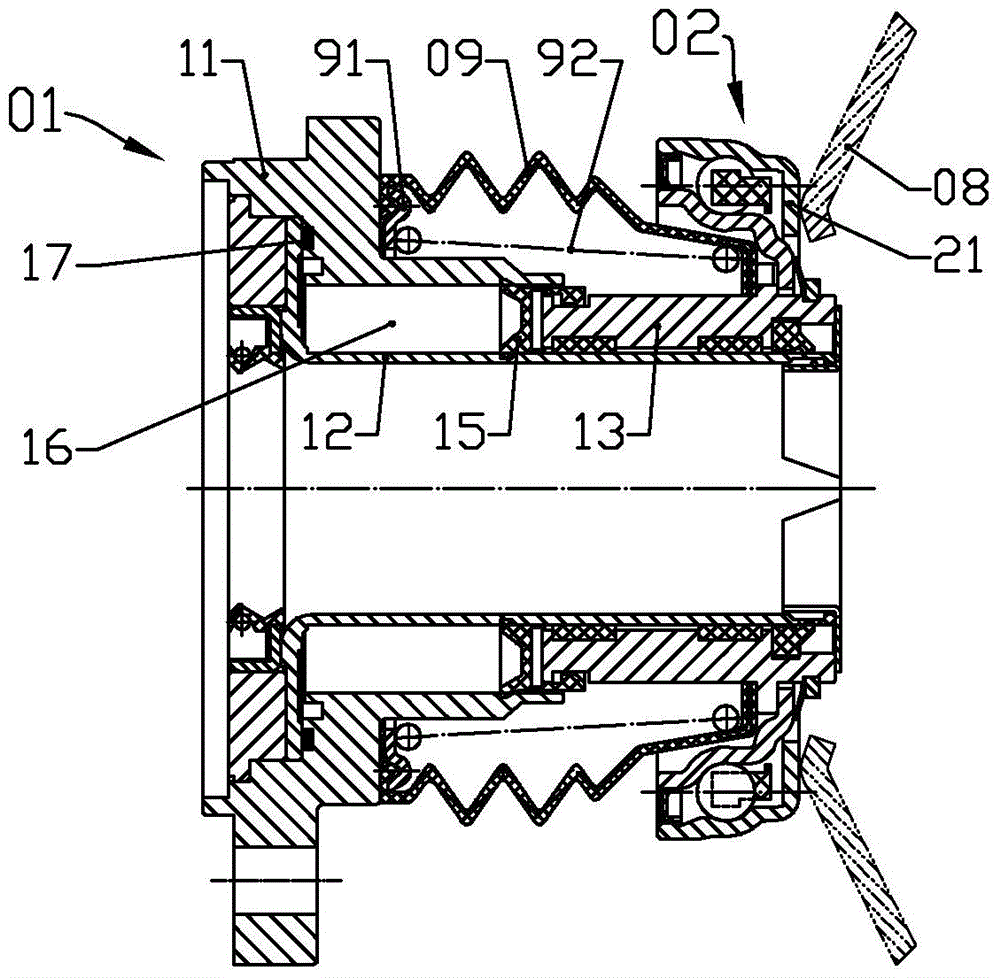

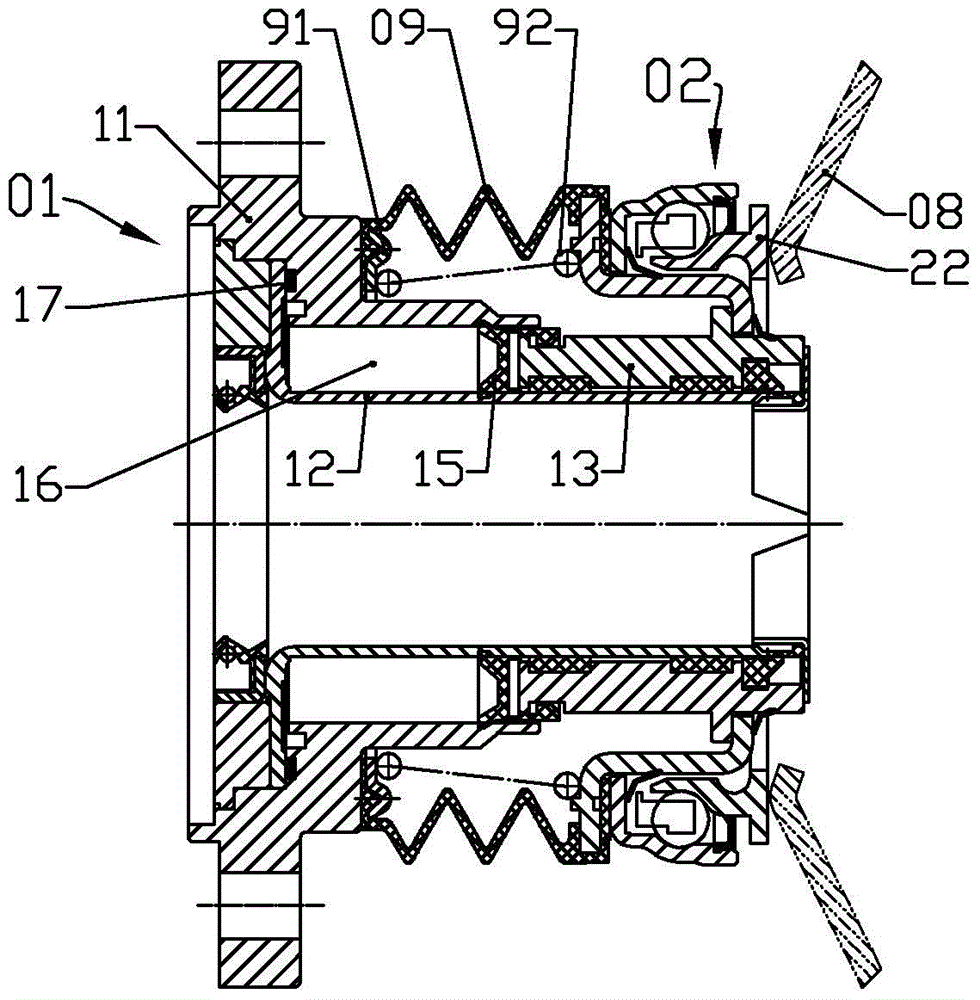

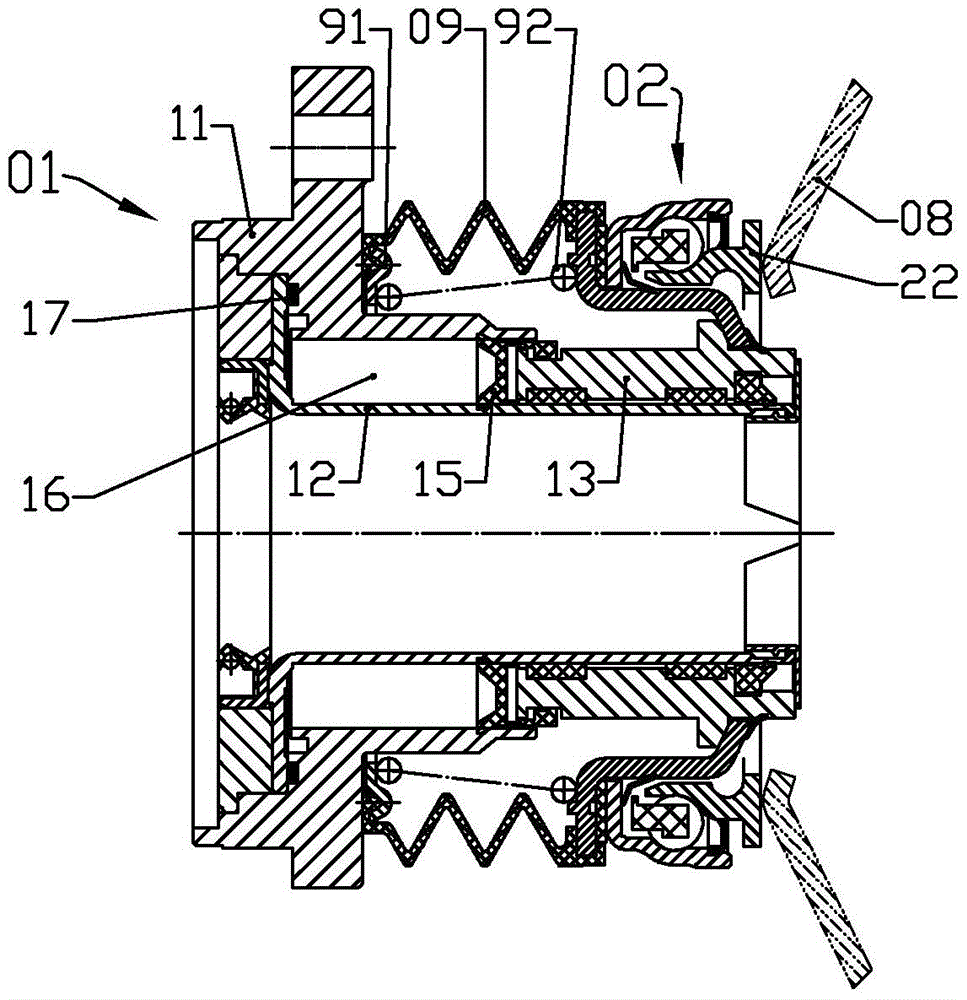

[0038] Figure 2-4 Shown is three structures of the adjustable center hydraulic clutch release bearing assembly with inner ring rotation of the present invention: it includes hydraulic cylinder 01 and release bearing 02, hydraulic cylinder 01 includes outer cylinder wall 11, inner cylinder wall 12. The plunger 13, the plunger 13 is located between the outer cylinder wall 11 and the inner cylinder wall 12 and can move through the cooperation of the seal 15 with the outer cylinder wall 11 and the inner cylinder wall 12. , A hydraulic chamber 16 is formed between the plungers 13, and the left ends of the outer cylinder wall 11 and the inner cylinder wall 12 are sealed by a seal 17. When the hydraulic oil enters the hydraulic chamber, the plunger can be pushed to move to the right, and then the plunger belt The release bearing approaches the clutch pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com