Device for measuring micro-impulse by adopting linear frequency modulation double-beam laser heterodyne method and torsion method and measuring method of device

A technology of linear frequency modulation and laser heterodyning, which is applied to measuring devices, force/torque/power measuring instruments, instruments, etc., and can solve problems such as low measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

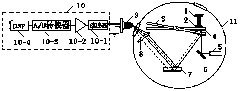

[0054] Specific implementation mode one: see figure 1 Describe this embodiment, the device for measuring micro-impulse using chirped double-beam laser heterodyne method and torsion method described in this embodiment, it includes pulse laser 1, working medium target 2, standard beam 3, and No. 2 plane mirror 4 , chirp laser 5, No. 1 plane mirror 6, plane standard mirror 7, converging lens 8, photodetector 9, signal processing system 10 and vacuum chamber 11;

[0055] The pulse laser 1, working medium target 2, standard beam 3, No. 2 plane mirror 4, chirp laser 5, No. 1 plane mirror 6, plane standard mirror 7 and converging lens 8 are all placed in a vacuum chamber,

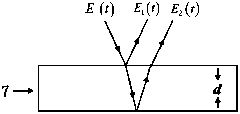

[0056] A working fluid target 2 is fixed on the plane at one end of the beam of the standard beam 3, and a No. 2 plane reflector 4 is pasted on the opposite position of the other side plane of the standard beam 3 opposite to the working fluid target 2; 3 In the horizontal state, the optical axis of the laser ligh...

specific Embodiment approach 2

[0060] Embodiment 2: The difference between this embodiment and the device for measuring micro-impulse using chirped double-beam laser heterodyne method and torsion method described in Embodiment 1 is that the signal processing system 10 includes a filter 10-1 , preamplifier 10-2, A / D converter 10-3 and DSP10-4, the signal output end of described filter 10-1 is connected with the amplified signal input end of preamplifier 10-2, preamplifier The amplified signal output end of 10-2 is connected with the analog signal input end of A / D converter 10-3, and the digital signal output end of A / D converter 10-3 is connected with the data signal input end of DSP10-4.

specific Embodiment approach 3

[0061] Specific embodiment three: This embodiment is based on the device for measuring micro-impulse by using chirped double-beam laser heterodyne method and torsion method described in specific embodiment one or two to realize the measurement method of micro-impulse. The specific process of this method is as follows:

[0062] Firstly, the pulsed laser 1, the chirp laser 5, the photodetector 9 and the signal processing system 10 are put into operation, and the swing angle θ′ of the standard beam 3 is obtained by measuring,

[0063] Second, according to

[0064] I ′ = 2 Jω D · θ ′ = 4 πJ DT ′ · θ ′ (Formula 1),

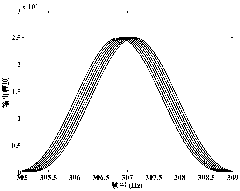

[0065] Calculate and obtain the micro-pulse I' generated by the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com