Projection cutting method for custom-made clothes

A clothing and projection technology, applied in the field of clothing manufacturing, can solve the problems of people who are not suitable for the information society, the professional equipment cannot be widely used, and the remote customization cannot be adapted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be described below in conjunction with the accompanying drawings and embodiments.

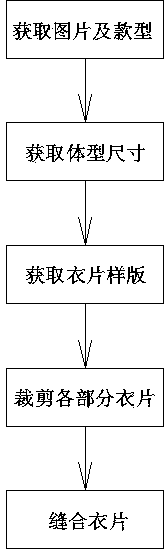

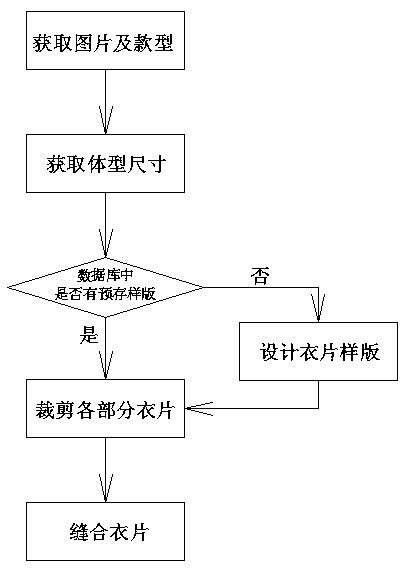

[0024] Such as figure 1 As shown, the present invention is a projection cutting method for customized clothing, which specifically includes the following steps:

[0025] (1) Obtain the body shape picture of the customizer and the style of the customized clothing;

[0026] (2) Perform pixel measurement on the body shape picture to obtain the body shape feature size;

[0027] (3) According to the body shape characteristic size and the customized clothing style, obtain the clothing piece samples of each part of the clothing;

[0028] (4) Sequentially project the garment piece samples of each part onto the fabric of the cutting table and cut out the garment pieces of each part along the projection line;

[0029] (5) Sew the parts of each part into a garment.

[0030] The projection cutting method of customized clothing of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com