High-voltage grounding wire clamp

A grounding clip, high-voltage technology, applied in the direction of connection, conductive connection, electrical component connection, etc., can solve the problems of difficult to hit the grounding clip, the grounding wire is swaying, and the sight is not good, so as to improve the safety. , good insulation performance, accurate operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

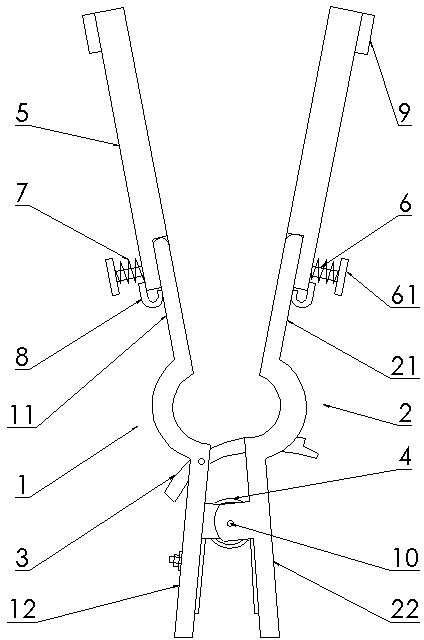

[0022] High voltage grounding clamps such as figure 1 As shown, it includes a left splint 1 and a right splint 2 hinged by a pin shaft 10, and a spring 4 is arranged at the pin shaft 10 to keep the left and right splints in a clamped state. The left splint 1 is divided into two parts by the pin shaft, which are respectively a slightly longer left clamp leaf 11 and a slightly shorter left clamp handle 12 , and the corresponding right clamp plate 2 is divided into a right clamp leaf 21 and a right clamp handle 22 . On the left clamping leaf 11 and the right clamping leaf 21, the positions equidistant from the pin shaft are provided with interlocking arc-shaped slots, and the trigger lever 3 is arranged between the left clamping leaf 11 and the right clamping leaf 21. There is a grounding wire device (the position where the bolt is set in the figure) and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com