Mating connection structure for shell

A technology of connecting structure and shell, applied in the direction of cabinet/cabinet/drawer parts, etc., can solve the problems of affecting the utilization rate of the internal space of the shell, occupying the internal space of the shell, deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

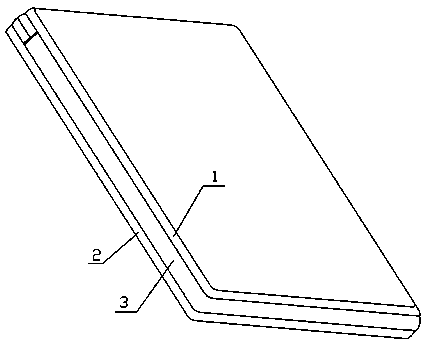

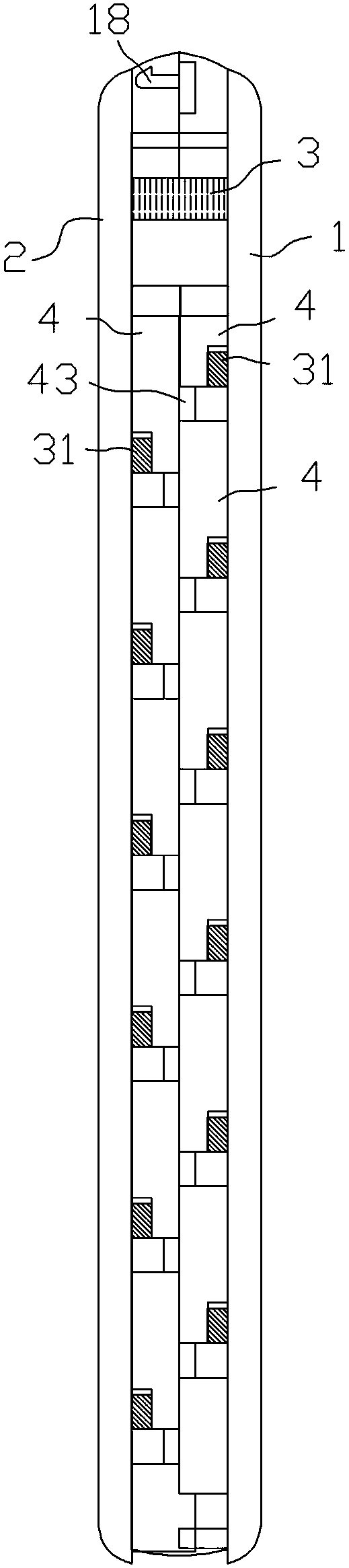

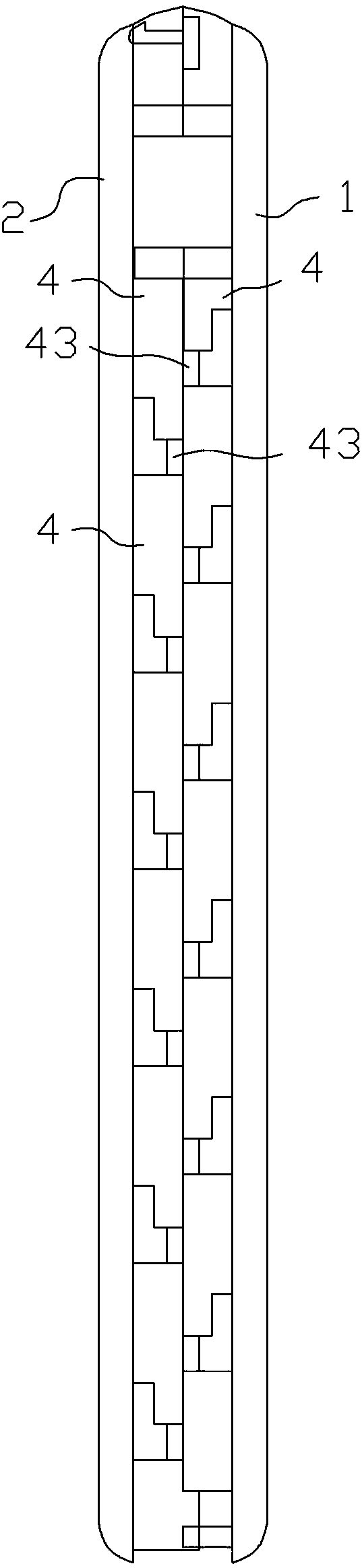

[0018] A shell fitting connection structure, such as figure 2 - Figure 6 and Figure 8 As shown, it includes a front shell 1 and a rear shell 2 that are combined into a shell, and a connecting frame 3 that connects the front and rear shells; the left and right sides of the front shell 1 and the rear shell 2 are respectively provided with multiple A connecting tooth 4 extending oppositely from the side of the sheet shell, a limit bayonet 42 is provided at the root of the connecting tooth; the connecting frame 3 is sleeved outside the connecting teeth of the front and rear sheet shells at the same time, including the inner connecting piece positioned at the inner side of the connecting tooth 31 and the outer connecting piece 32 on the outside of the connecting teeth, the inner and outer connecting pieces are provided with limiting blocks 33 at the gaps between the connecting teeth of the front shell to connect the front sides of the inner and outer connecting pieces, and conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com