wind power plant

A technology of wind power generation device and generator, which is applied in the direction of wind power generation, wind engine, wind engine control, etc., can solve the problems of increasing structural space and complexity, and achieve the effect of simple and efficient rotary structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

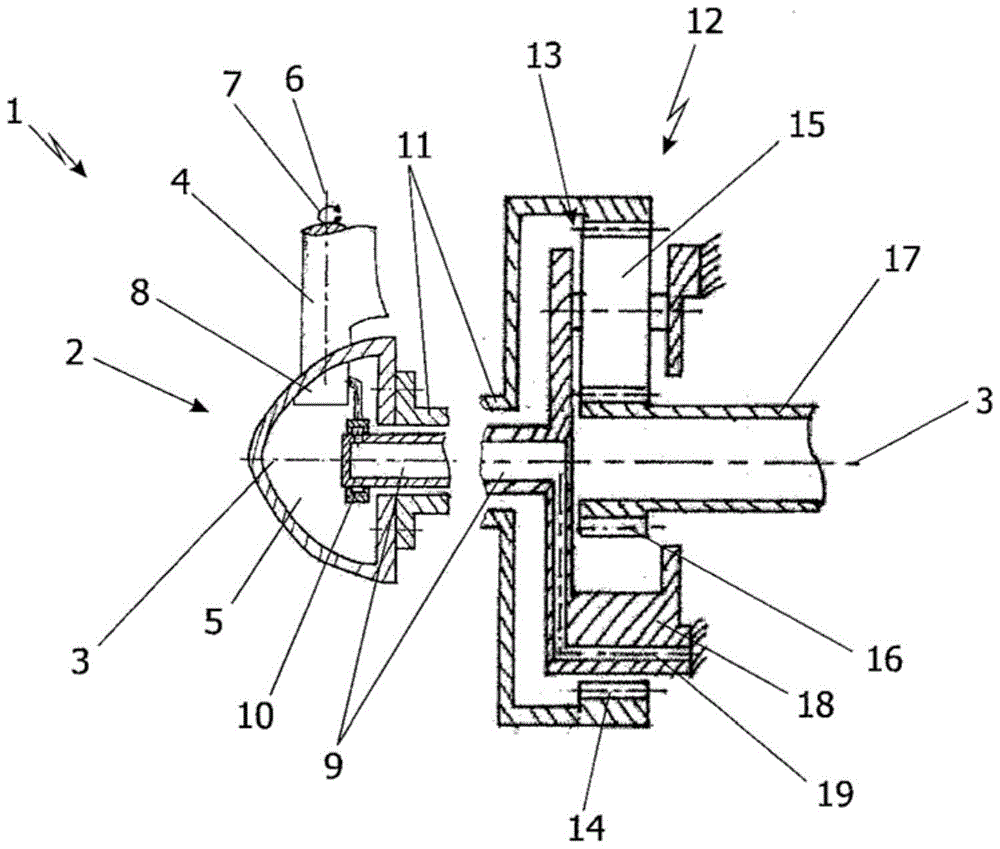

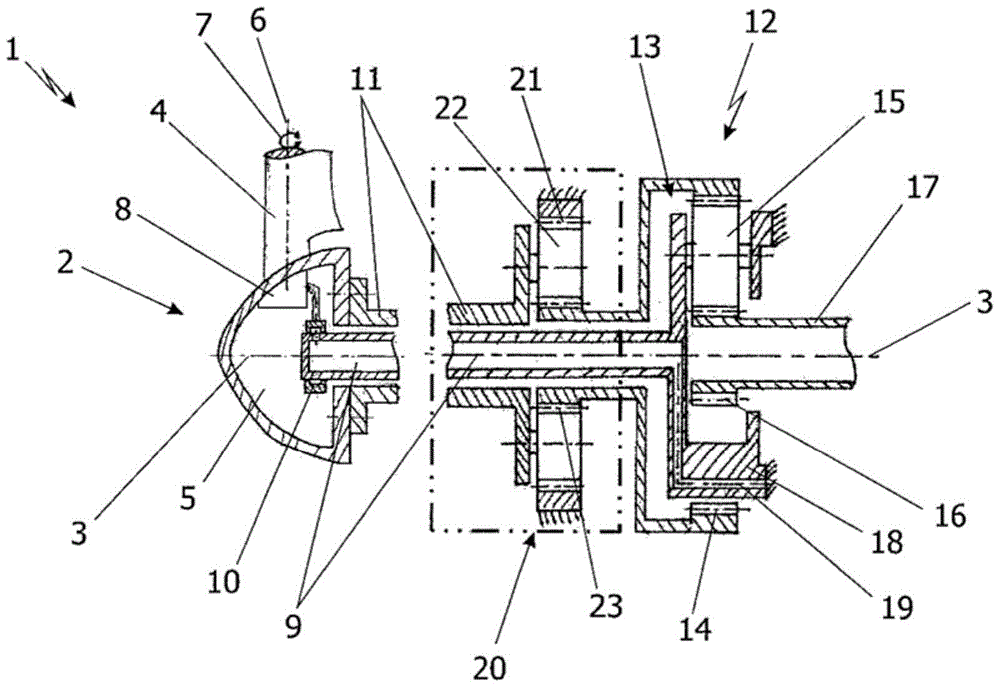

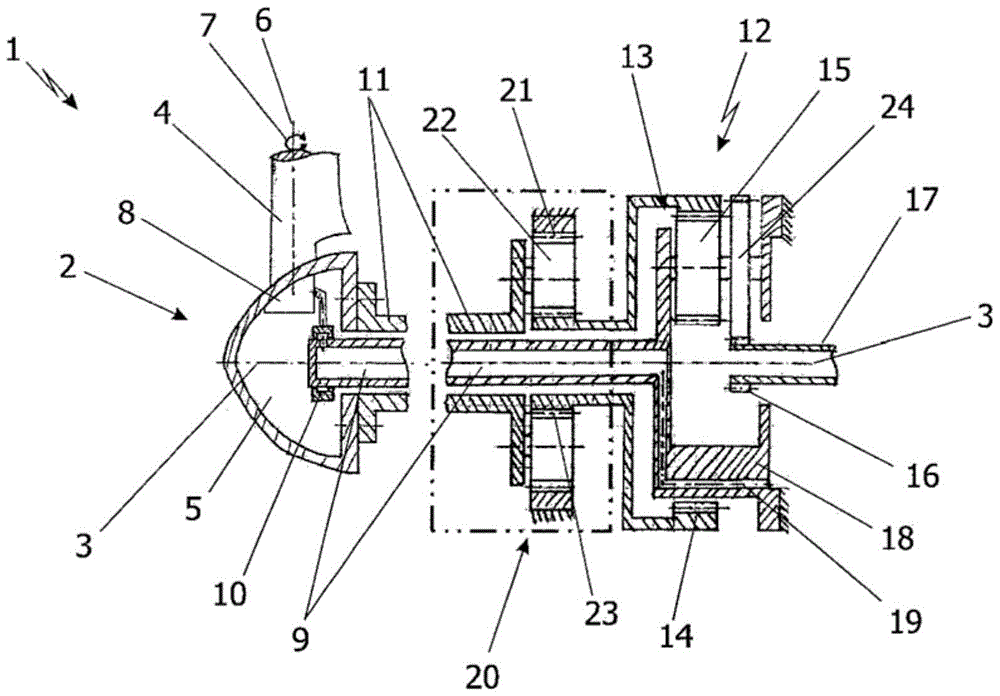

[0014] exist figure 1 Parts of the wind power plant 1 that are relevant to the invention can be seen in the view of . This part essentially consists of the rotor 2 rotating about the rotor axis 3 . The rotor 2 is formed from a plurality of rotor blades 4 , only one of which is schematically shown in this section. The rotor blades 4 converge into a central rotor hub 5 . The rotor blade 4 is adjustable about its own longitudinal axis 6 , which is generally, but not necessarily, perpendicular to the axis of rotation 3 , as is shown schematically by the arrow designated 7 . The adjustment of the rotor blades 4 is known from the prior art. This adjustment is typically effected from the inside of the rotor hub 5 via an adjustment device 8 , which is again only shown as a box. However, the configuration of the adjusting device 8 is known from the prior art.

[0015] In order to operate the adjusting device 8 , adjusting energy must be delivered into the region of the rotor hub 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com