High aspect ratio stacked MLCC design

A high aspect ratio, multi-layer ceramic technology, applied in the field of improved external lead design, high integration density electronic components, can solve the problems of easy dumping, increased aspect ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

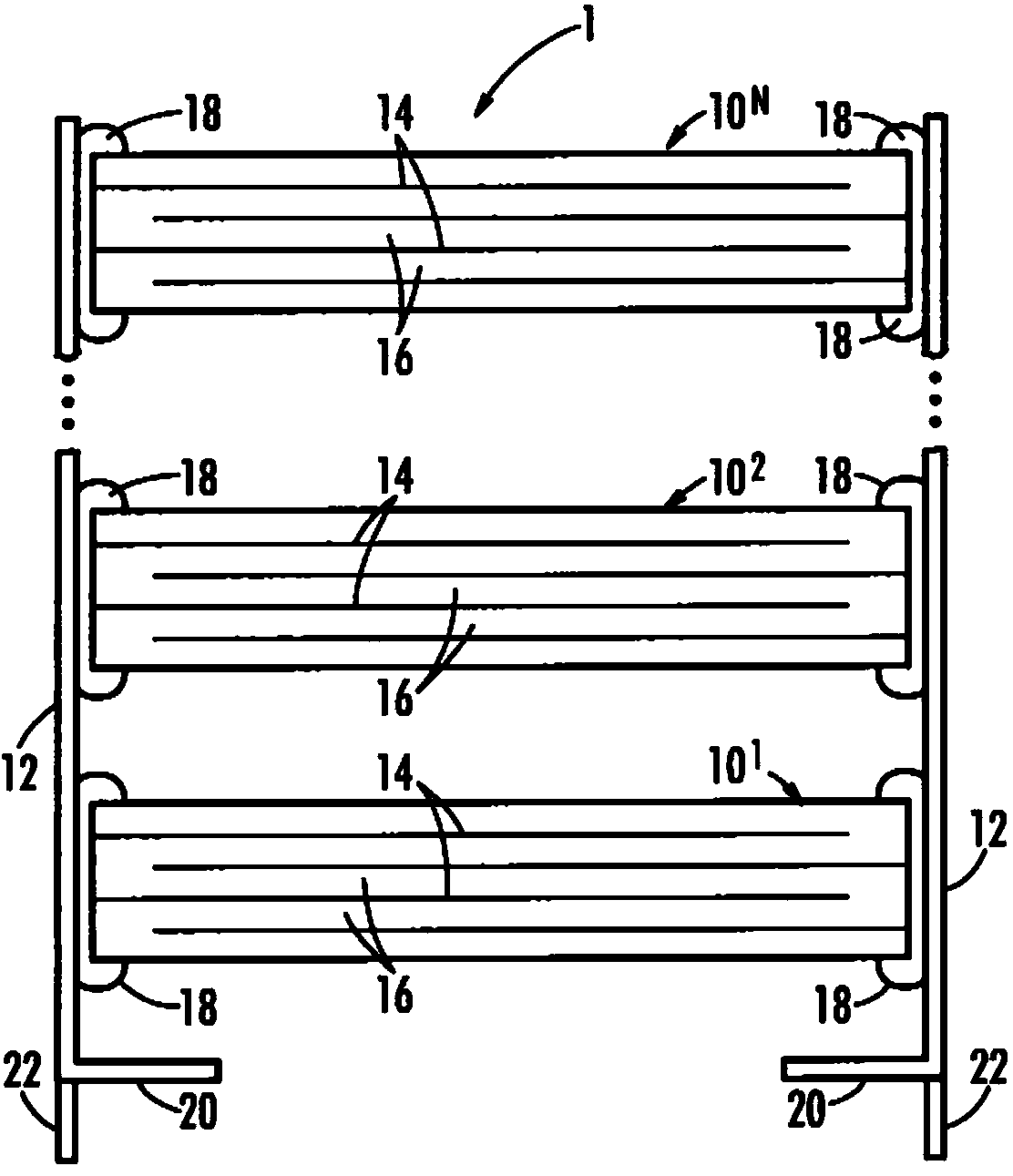

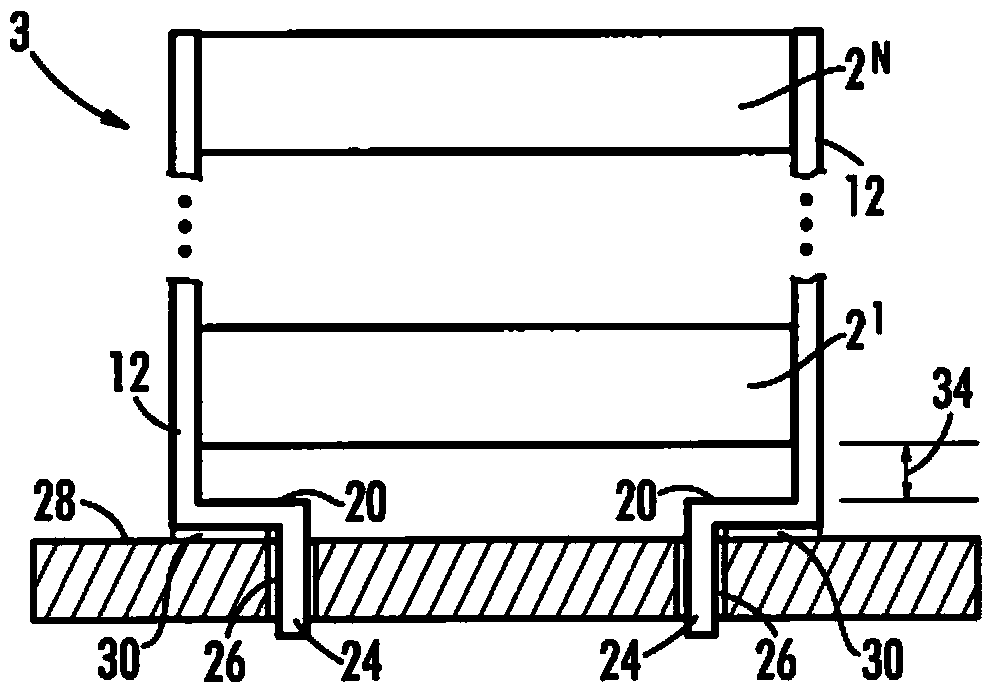

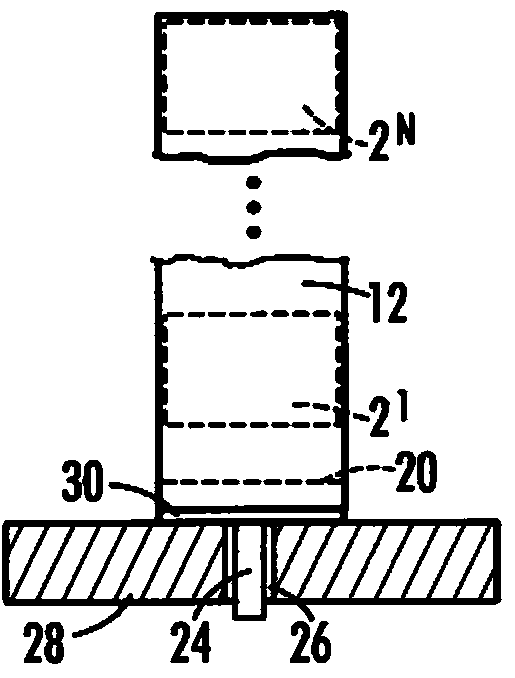

[0040] The present invention is directed to an improved lead structure for stacked electronic components, in particular to stacked MLCCs. More specifically, the present invention is directed to lead structures that include positioning pins that allow for aspect ratios such as Figure 25 The height (H) to shortest width (W) ratio shown is very large while minimizing the possibility of the stacked components shifting or toppling during handling.

[0041] The present invention provides a capacitor stack, most preferably an MLCC capacitor stack, that allows the designer to take advantage of the vertical space on the board to increase the density of capacitors in a given area of the board, thereby enhancing functionality such as capacitance density. This is accomplished by incorporating into the leadframe stabilizing feet designed for surface mount applications, where the stabilizing feet extend into the void and preferably through the substrate or board, while the leadframe pins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com