Commutator motor

A technology for commutators and motors, applied in the direction of DC commutators, collectors, rotating collectors, etc., can solve the problems of reduced stability, service life, large tolerances, etc., and achieve stable guidance, low cost, and reliable support Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

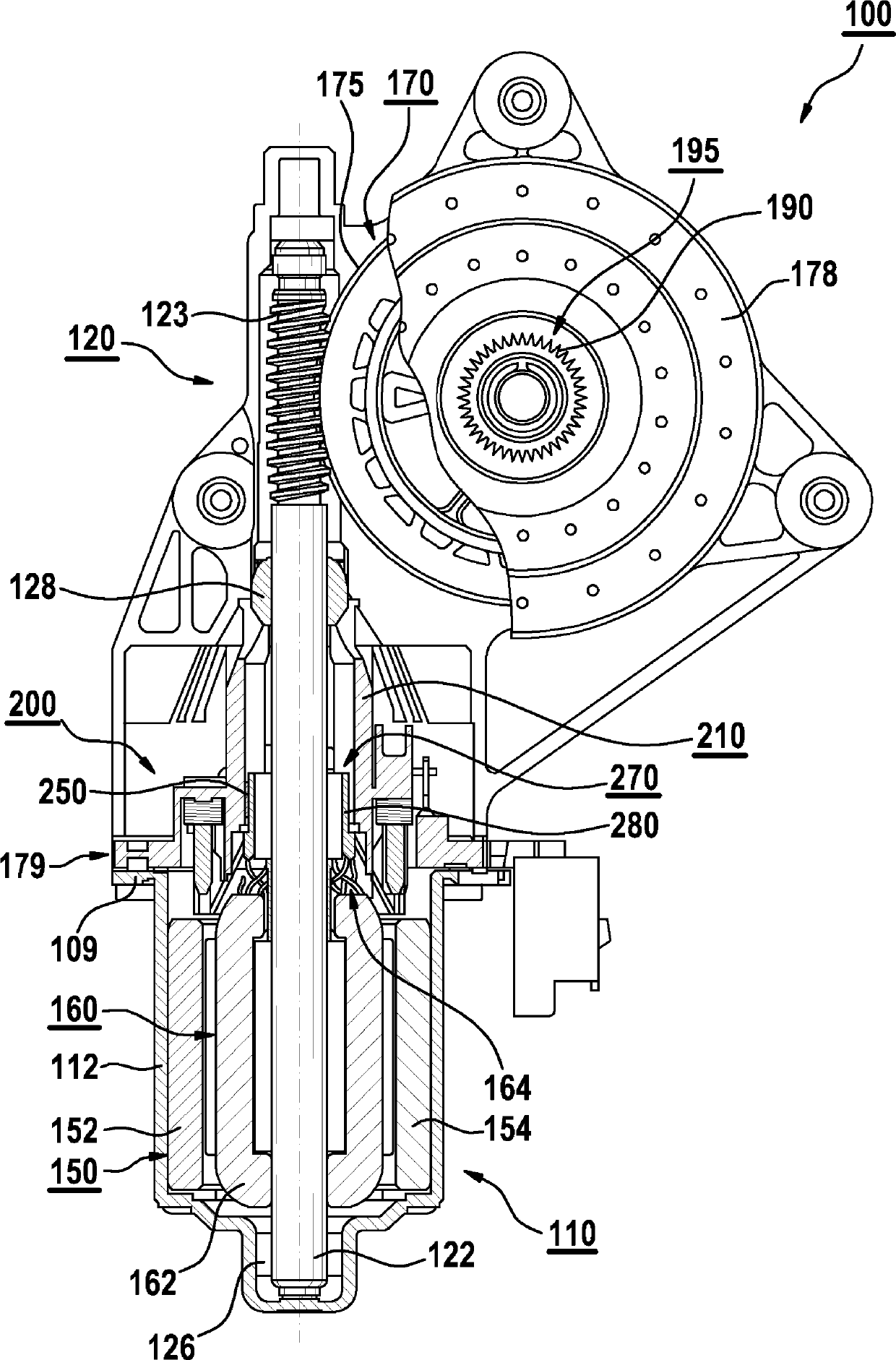

[0029] figure 1 An exemplary drive device 100 is shown, which as shown has a drive motor 110 and a switching mechanism 120 coupled to the drive motor. The drive device 100 is preferably used as a drive device for electric window regulators in a motor vehicle. However, it should be pointed out that the drive device 100 is not restricted to use for a window regulator, but can be used for a plurality of different actuating drives. For example, the device 100 can alternatively be used in an actuating drive for a seat adjuster.

[0030] The drive motor 100 can be controlled or adjusted in such a way that both reversible operation and presetting are possible with respect to the desired rotational speed. By way of example, the drive motor 110 is equipped with a motor housing 112 which has a fastening flange 109 . Switching mechanism 120 is for example equipped with a gear housing 178 which has a fastening section 179 . The fastening flange 109 of the motor housing 108 is fastened...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com