A swing type weeding manipulator between seedlings

An oscillating, manipulator technology, applied in the fields of soil preparation machinery, agricultural machinery and implements, weed elimination equipment, etc., can solve the problems of limited application scope, complicated control, collapse of the cutter head, etc., to achieve simple control and ensure coverage. , the effect of increasing hardware life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In the following, the present invention is further explained in detail in conjunction with the drawings and embodiments.

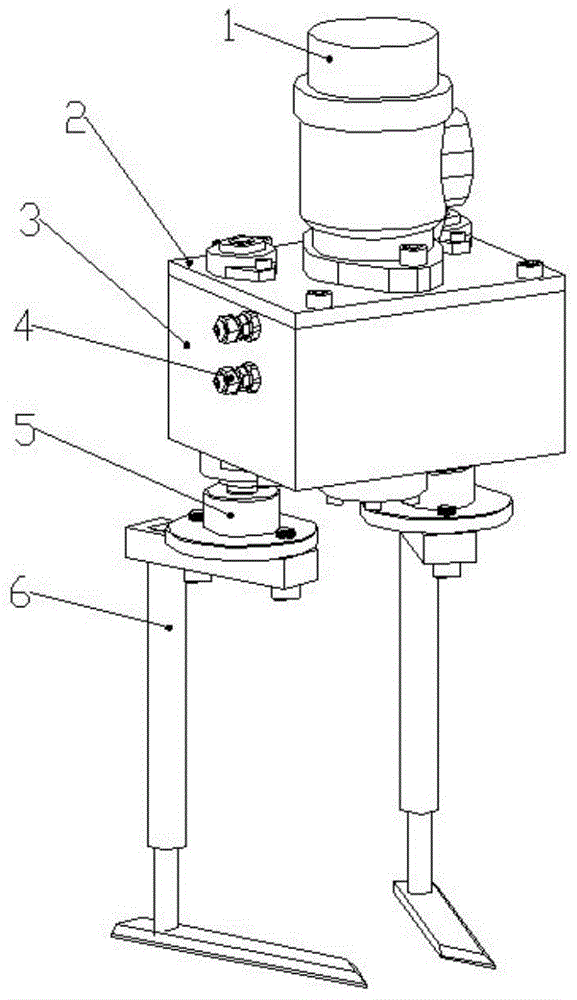

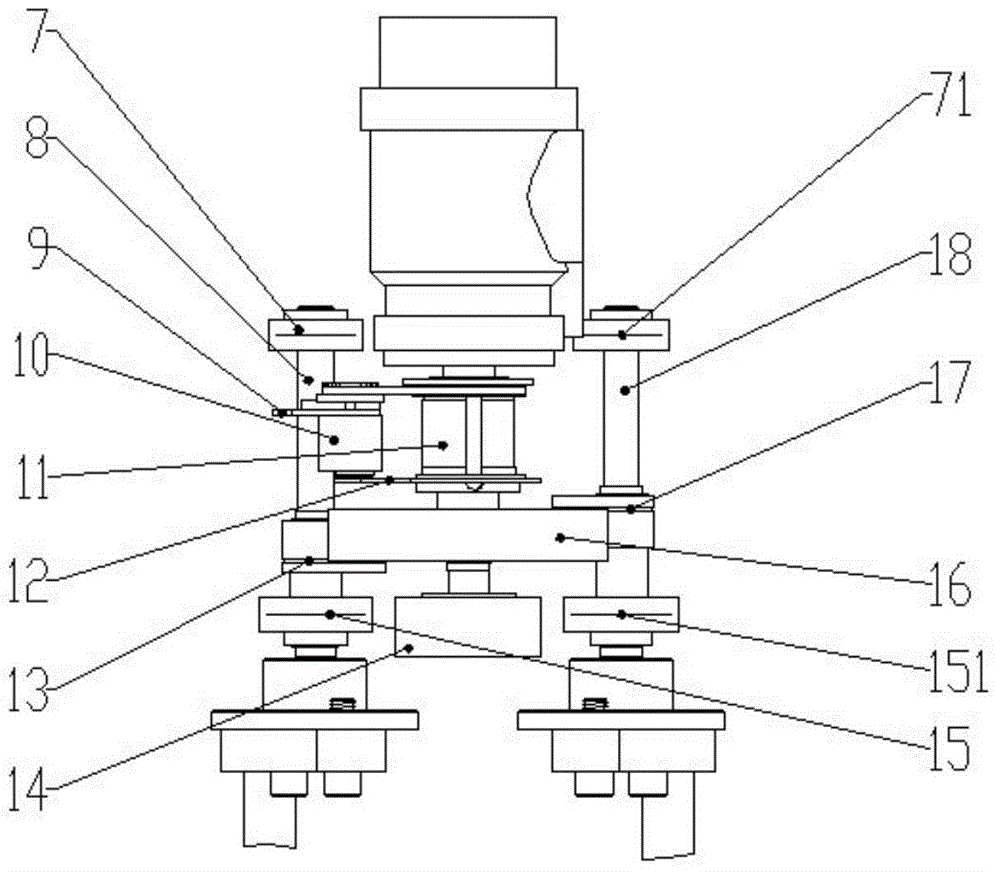

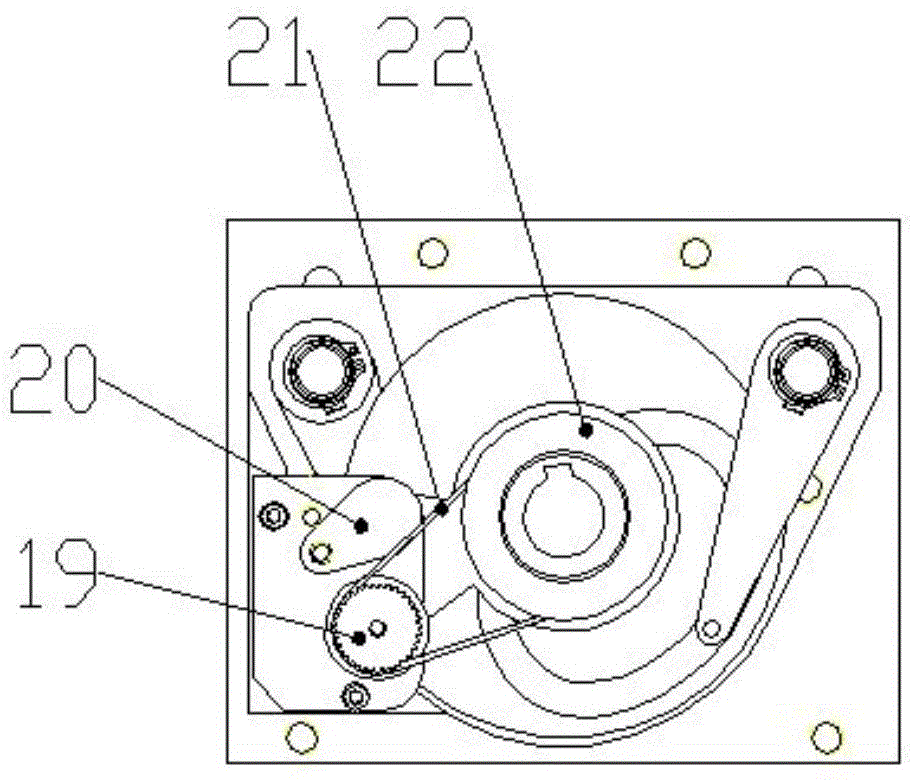

[0058] figure 1 It is a schematic diagram of the external structure of the swing type weeding manipulator between seedlings of the present invention; figure 2 and image 3 They are the front view and the top view of the inner structure of the box of the manipulator respectively.

[0059] Wherein, the swing type inter-seedling weeding manipulator includes a hydraulic motor 1, which can also be replaced by a motor, and the hydraulic motor 1 is installed on the box cover 2 by bolts, and the box cover 2 is installed on the box by screws. On the body 3; the output shaft of the hydraulic motor 1 is connected with the transmission shaft 11 through a flat key, and the torque is transmitted to the transmission shaft 11, which drives the transmission shaft 11 to rotate.

[0060] The transmission shaft 11 is supported on the belt seat bearing 14, and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com