Detachable self-locking type zipper puller

A zipper puller and self-locking technology, which is applied in the field of zipper pullers, can solve the problems of small caps, difficulties, jamming, etc., and achieve the effect of firm assembly, high production continuity, and not easy to twist

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

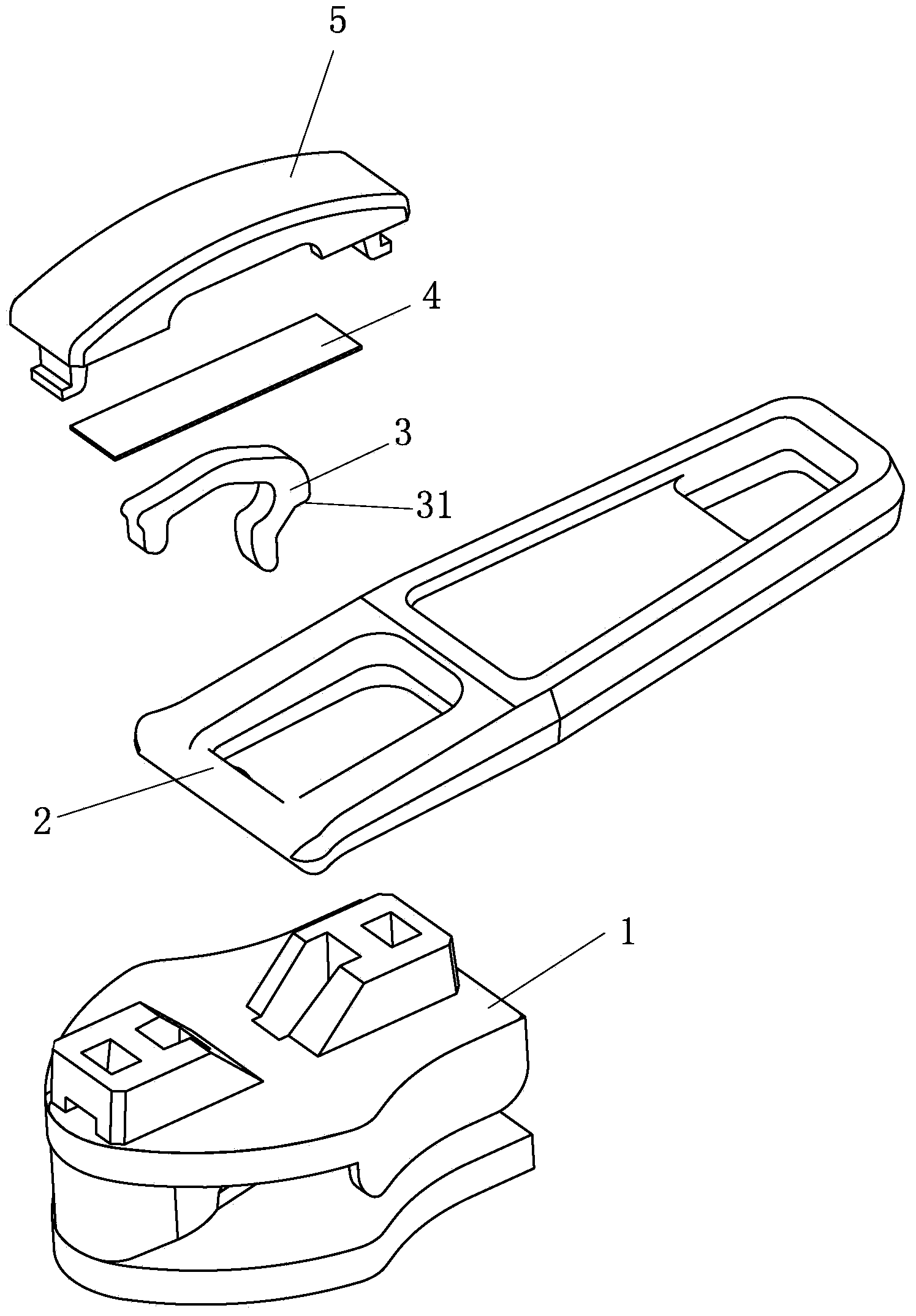

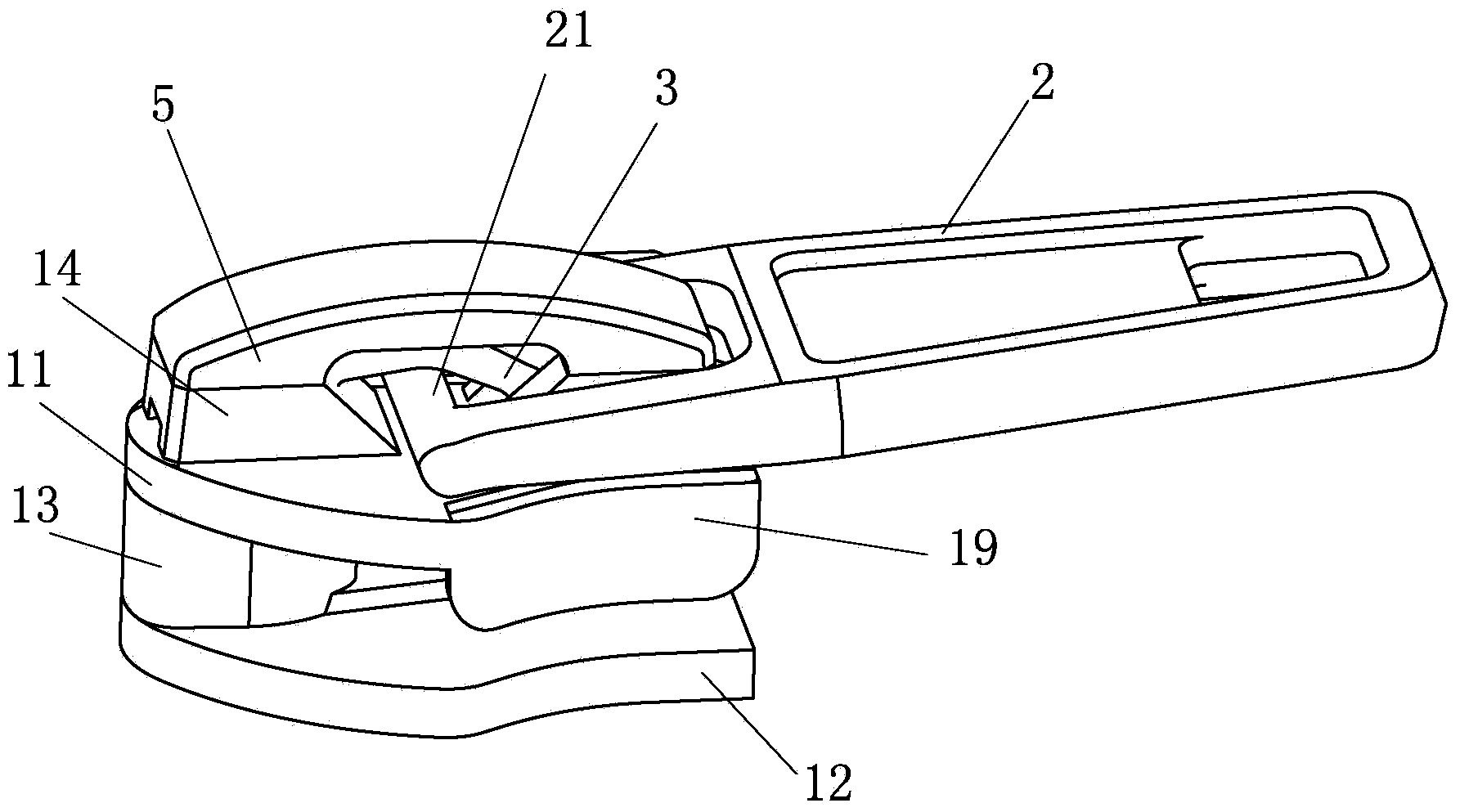

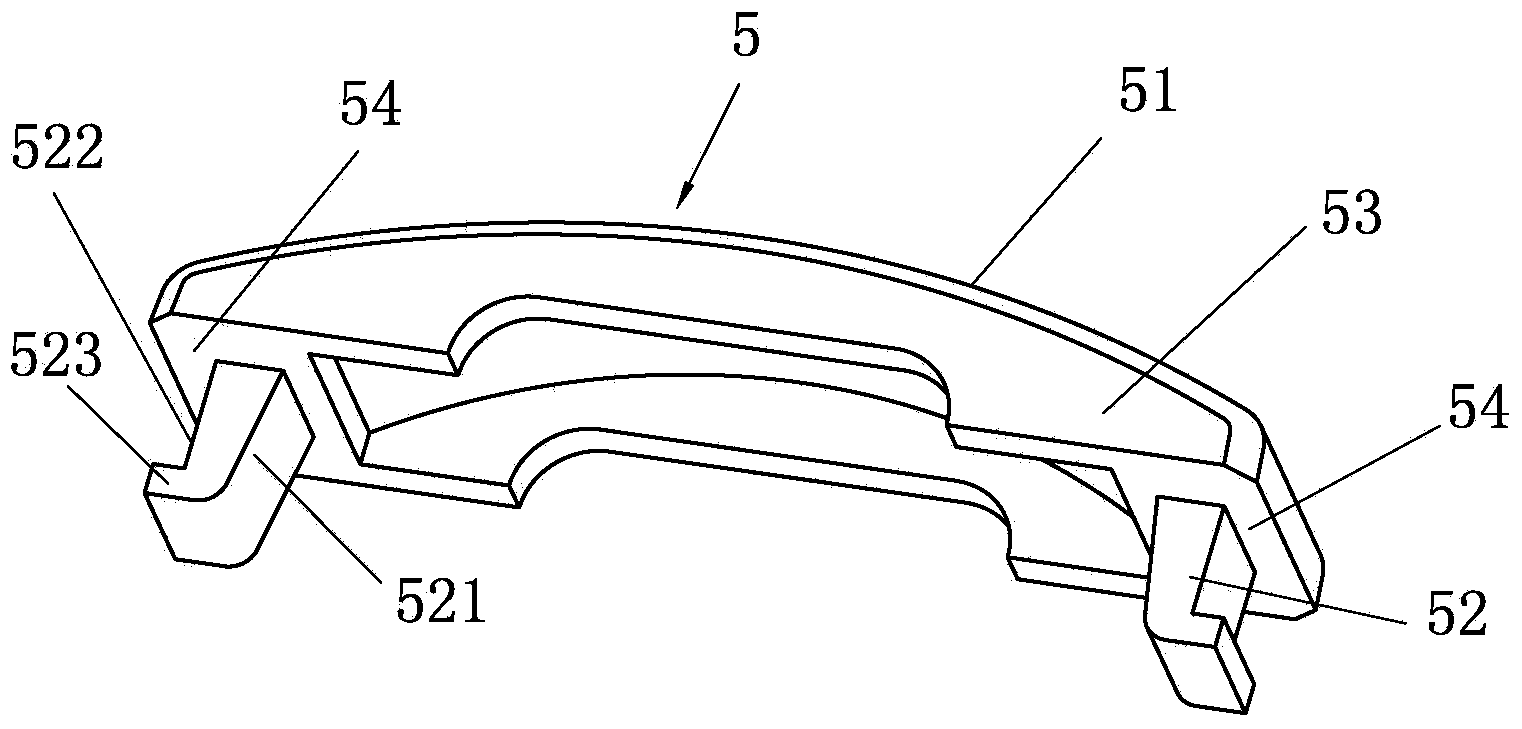

[0025] Such as Figure 1 to Figure 4 As shown, a detachable self-locking zipper head includes a slider body 1, a self-locking device, a pull tab 2 and a cap 5, and the slider body 1, the pull tab 2 and the cap 5 can utilize thermoplastic resin (such as Polyamide, polypropylene) or thermoplastic resin with wear-resistant reinforcing agent is made by injection molding. Of course, these three parts can also be made of metal material through die casting. Wherein, the slider body 1 has an upper plate 11 and a lower plate 12 supported and connected by a guide post 13. The upper plate 11 and the lower plate 12 have a large end and a small end, and the width of the large end is greater than that of the small end. In the following description , the big end of the slider body 1 is defined as the front end, and the small end is defined as the rear end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com