Gas filter device and gas purifying method utilizing same

A filter device and gas filter technology, applied in chemical instruments and methods, separation methods, dispersed particle filtration, etc., can solve the problems of low space utilization rate of gas filter installation site and difficulty in manufacturing filter elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

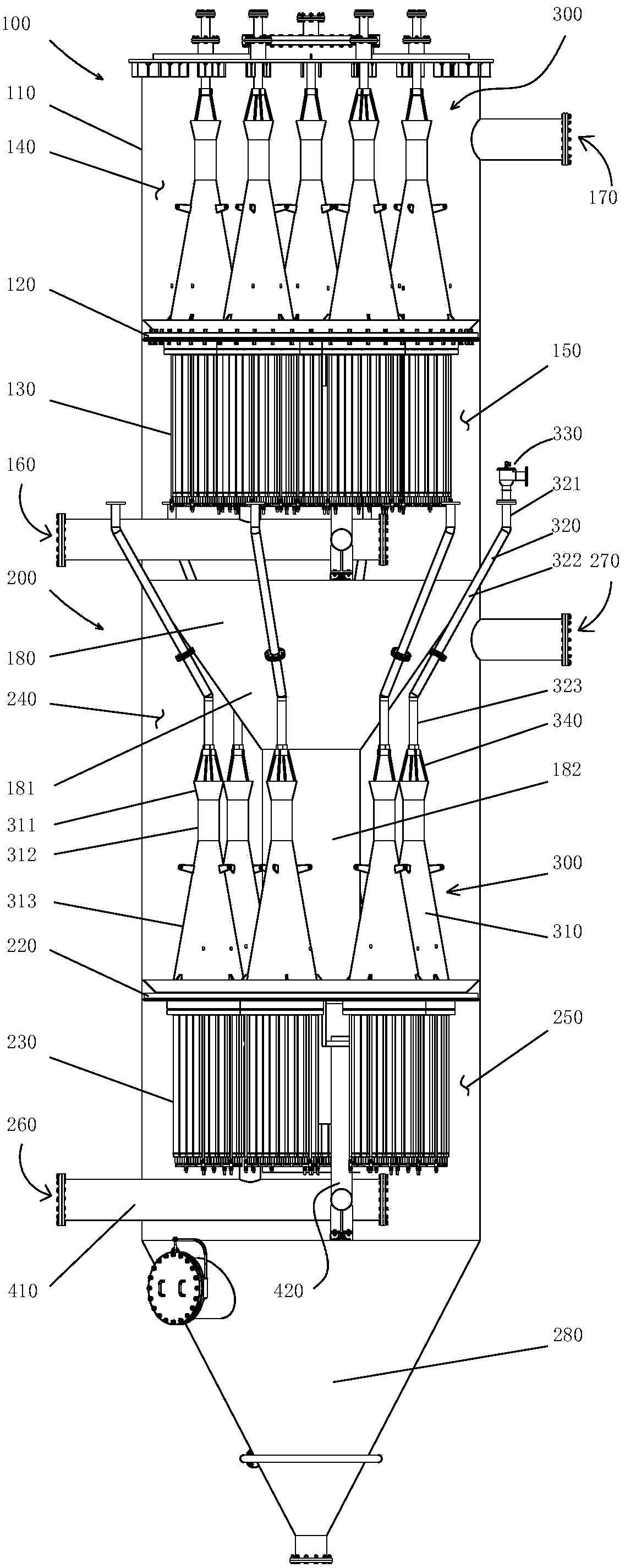

[0012] Such as figure 1As shown, the first gas filter 100 includes a first outer cylinder 110, a first orifice plate 120 installed in the first outer cylinder 110, and a first filter element 130 installed on the first orifice plate 120, the first The outer cylinder body 110 is located above the first orifice plate 120 to form a first clean air chamber 140, and the inside of the first outer cylinder body 110 is located below the first orifice plate 120 to form a first raw gas chamber 150. The first outer cylinder body 110 is provided with There is a first air inlet 160 connected to the first raw air chamber 150 and a first exhaust port 170 connected to the first clean air chamber 140, and the lower part of the first outer cylinder 110 converges to form a first product. Ash discharge part 180; the second gas filter 200 is provided below the first gas filter 100, and the second gas filter 200 includes a second outer cylinder 210 and a second hole installed in the second outer cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com