A control method and application of anti-tower defect of asymmetrical side guide plate of coiler

A control method and coiler technology, which are applied in the control field of object operation, can solve problems such as easy generation of tower defects, and achieve the effects of saving manpower and material resources, less investment, and improving coil quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

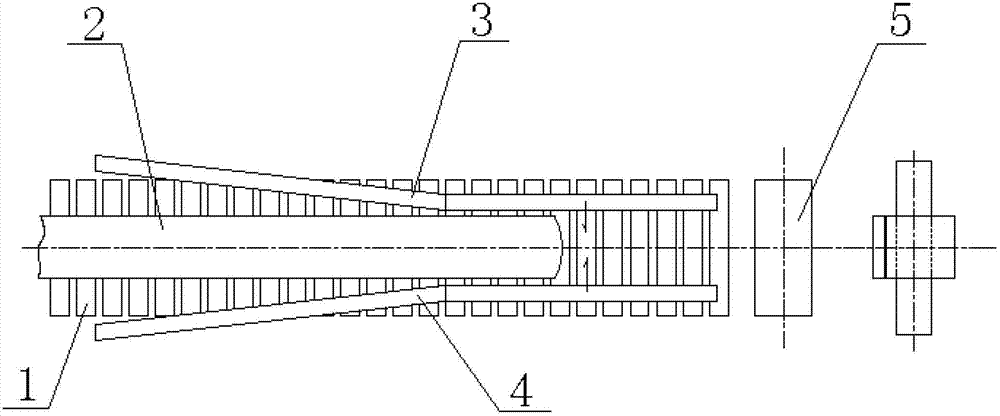

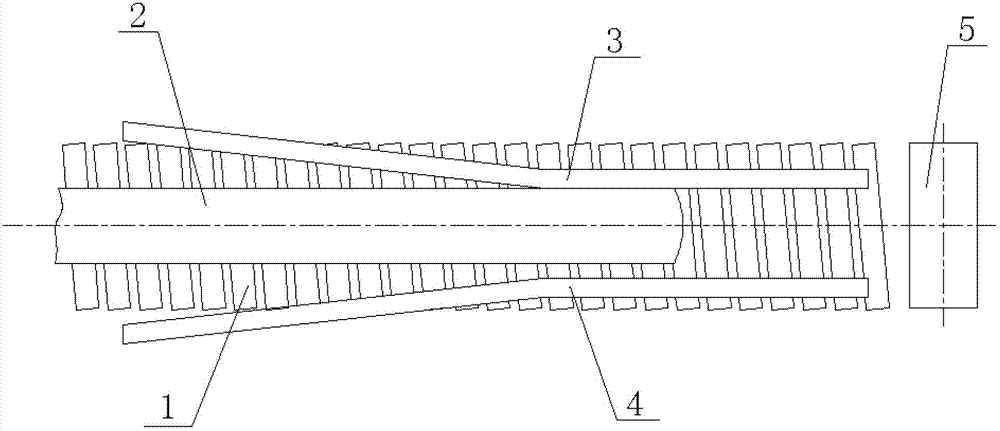

[0046] This embodiment is applied to 2050 hot rolling coiler, as image 3 and Figure 4 As shown, a control method for the anti-tower defect of the asymmetric side guide plate of the coiler:

[0047] 1) The 80-120 conveying rollers of the conveying roller group 1 of the coiler that first contact the strip steel 2 are arranged in a skewed manner, and the 2050 hot rolling coiler in this embodiment is arranged in a skewed manner by selecting 100 conveying rollers;

[0048] 2) The deflection arrangement of the conveying rollers is specifically to form a deflection angle C from the original 90° right angle deflection between the axis A of each conveying roller and the rolling center line B, so that the conveying roller group of the coiler 1. While rotating and pushing the strip steel 2 forward, it forms a directional thrust towards one side, making it run against the side guide plate on this side;

[0049] 3) Adjust the center line of the side guide plate as follows:

[0050] 3....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com