Pipeline support structure

A technology of pipeline supports and pillars, applied in the direction of pipeline supports, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of oil pipeline breakage, short service life, trouble, etc., to reduce pipeline wear, ensure normal transportation, reduce cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments provided by the present invention are described in further detail in conjunction with the accompanying drawings:

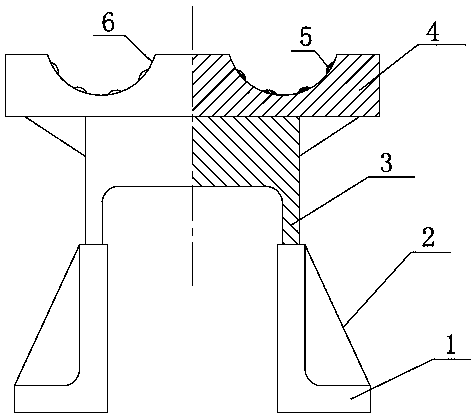

[0012] Such as figure 1 As shown, a pipeline support structure includes a base 1 and a pillar 3, a support arm 4 is arranged on the upper surface of the pillar 3, and a pipe groove 6 is respectively arranged on both sides of the support arm 4, and the cross-sectional shape of the pipe groove 6 is Semi-circular, elastic protrusions 5 are evenly distributed on the surface of the pipe groove 6, and a reinforcing rib 2 is added obliquely between the two sides of the base 1 and the support arm 4.

[0013] When in use, the base 1 is fixedly installed on a plane, and the supported pipe is placed in the pipe groove 6 of the bracket structure for support.

[0014] The pipeline bracket of the present invention can support the two-way pipeline at the same time. In addition, the arrangement of the elastic protrusion reduces the stress between the pipeline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com