A kind of stainless steel strip composite pipe and its preparation method

A technology of stainless steel and composite pipes, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of outer glass steel pipe damage, gaps that cannot be strengthened, and inconvenient installation, etc., to achieve convenient construction, reduce material loss, and install convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Below in conjunction with accompanying drawing, the present invention will be further described:

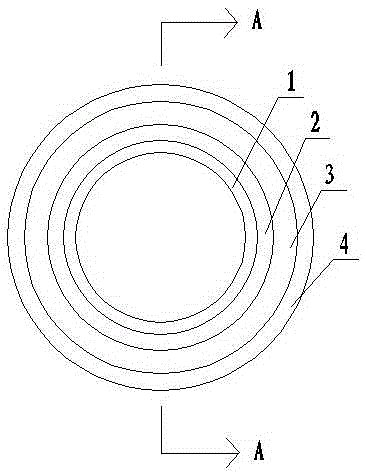

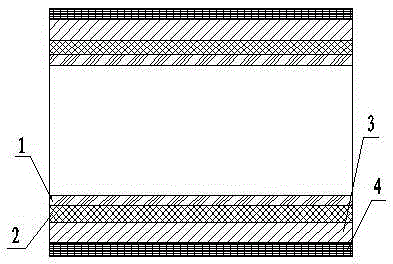

[0036] Such as figure 1 , figure 2 As shown, a stainless steel strip composite pipe, the stainless steel strip composite pipe is composed of different glass fiber materials, and its composite pipe has a four-layer structure, from inside to outside: the first layer is stainless steel Wound inner cylinder 1, the second layer is the inner lining layer 2 wound with glass fiber surface mat, the third layer is the structure layer 3 wound with glass fiber yarn, glass fiber cloth and knitted mat, the fourth layer is the glass fiber surface mat The winding protective layer 4 is bonded by an adhesive between each layer.

[0037] The thickness of the inner cylinder 1 is 0.2mm-1mm, the thickness of the lining layer 2 is 1-2mm, the thickness of the structural layer 3 is wound according to different pressure levels, generally 6mm-20mm, and the thickness of the protective layer 4 is ...

Embodiment 2

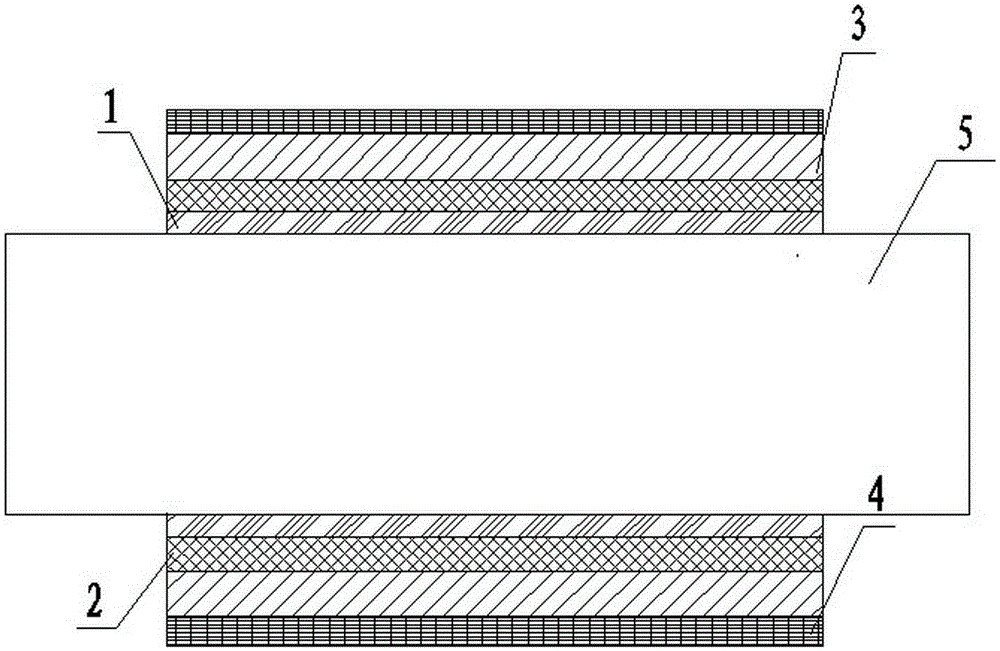

[0039] Such as image 3 As shown, a stainless steel strip composite pipe, the stainless steel strip composite pipe is composed of different glass fiber materials, and its composite pipe has a four-layer structure, from inside to outside: the first layer is stainless steel Wound inner cylinder 1, the second layer is the inner lining layer 2 wound with glass fiber surface mat, the third layer is the structure layer 3 wound with glass fiber yarn, glass fiber cloth and knitted mat, the fourth layer is the glass fiber surface mat Wrapped protective layer4.

[0040] The preparation method of the above-mentioned stainless steel strip composite pipe comprises the following steps:

[0041] (1) A stainless steel strip is wound on the mandrel 5 to form the inner cylinder 1;

[0042] (2) Coating an adhesive on the surface of the wound inner cylinder 1;

[0043] (3) Wrap the glass fiber surface mat on the surface of the inner cylinder 1 coated with the adhesive to form the inner lining ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com