A slope optical fiber Bragg grating multi-point displacement sensor and its application method

A technology of displacement sensor and optical fiber, applied in instruments, optical devices, measuring devices, etc., to achieve strong corrosion resistance, easy operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

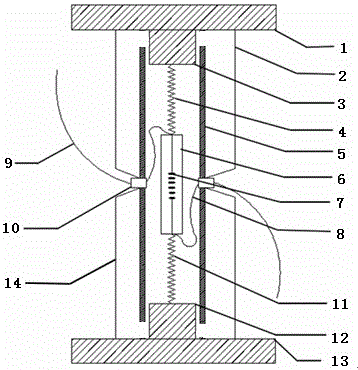

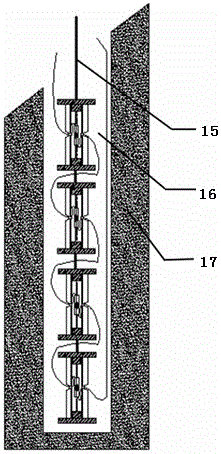

[0049] Embodiment 1: as Figure 1-5 As shown, a slope optical fiber Bragg grating multi-point displacement sensor includes an upper flange 1, an upper elastic protection ring 2, an upper pull rod 3, an upper displacement spring 4, a protective steel pipe 5, an elastic steel sheet 6, and an optical fiber Bragg grating 7. The lower connected optical fiber 8, the upper connected optical fiber 9, the steel pipe optical fiber outlet hole 10, the lower end displacement spring 11, the lower end pull rod 12, the lower end flange 13, and the lower end elastic protection ring sleeve 14; wherein the base of the upper end pull rod 3 is tapped and The upper flange 1 is connected, the other end of the upper pull rod 3 is connected with one end of the upper displacement spring 4, the other end of the upper displacement spring 4 is connected with the elastic steel sheet 6, and the optical fiber Bragg grating 7 is pasted on the elastic steel sheet 6, and the elastic steel The lower end of shee...

Embodiment 2

[0057] Embodiment 2: as Figure 1-5 As shown, a slope optical fiber Bragg grating multi-point displacement sensor includes an upper flange 1, an upper elastic protection ring 2, an upper pull rod 3, an upper displacement spring 4, a protective steel pipe 5, an elastic steel sheet 6, and an optical fiber Bragg grating 7. The lower connected optical fiber 8, the upper connected optical fiber 9, the steel pipe optical fiber outlet hole 10, the lower end displacement spring 11, the lower end pull rod 12, the lower end flange 13, and the lower end elastic protection ring sleeve 14; wherein the base of the upper end pull rod 3 is tapped and The upper flange 1 is connected, the other end of the upper pull rod 3 is connected with one end of the upper displacement spring 4, the other end of the upper displacement spring 4 is connected with the elastic steel sheet 6, and the fiber Bragg grating 7 is pasted on the elastic steel sheet 6, and the elastic steel The lower end of sheet 6 is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com