Sand substance wriggling and moving collector

A collector and material technology, which is applied in the field of instruments for measuring wind and sand flow, can solve the problems of large measurement results, no consideration of friction coefficient between sand material and observation surface, and inconsistent moving speed of sand particles, so as to improve accuracy and structure Simple, simple and practical production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

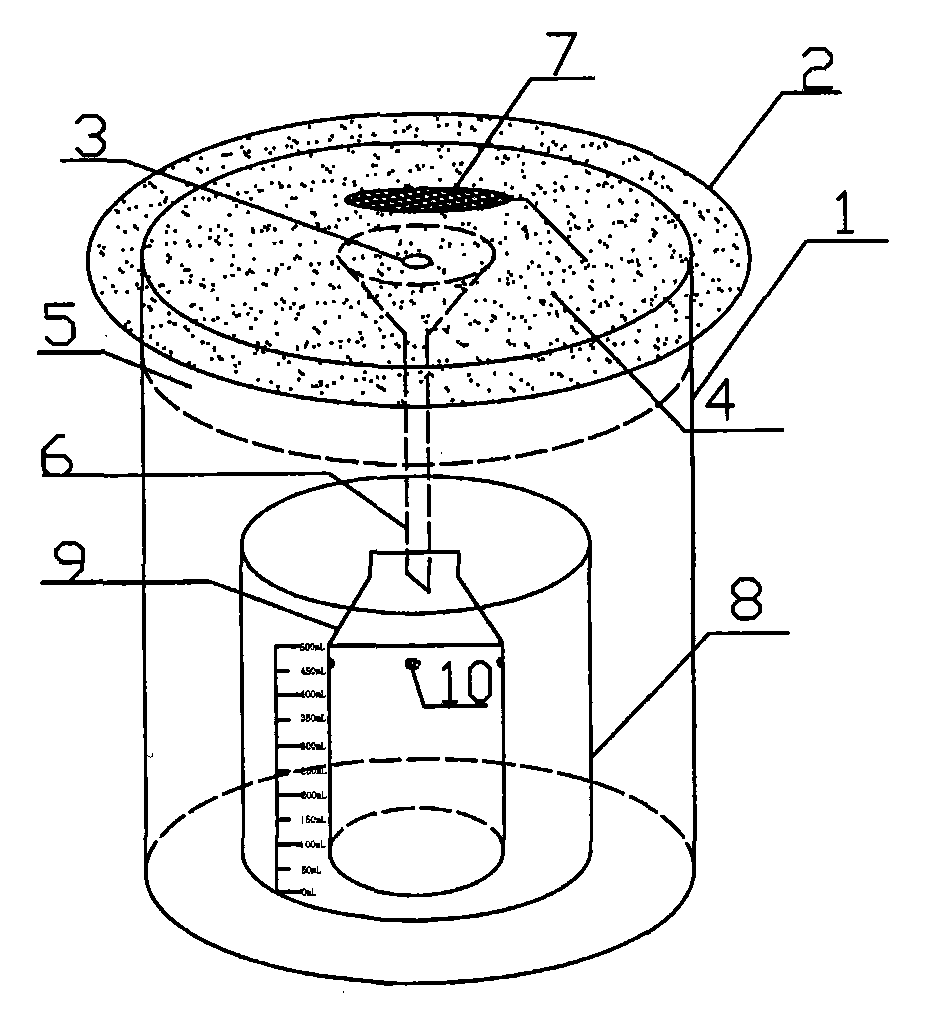

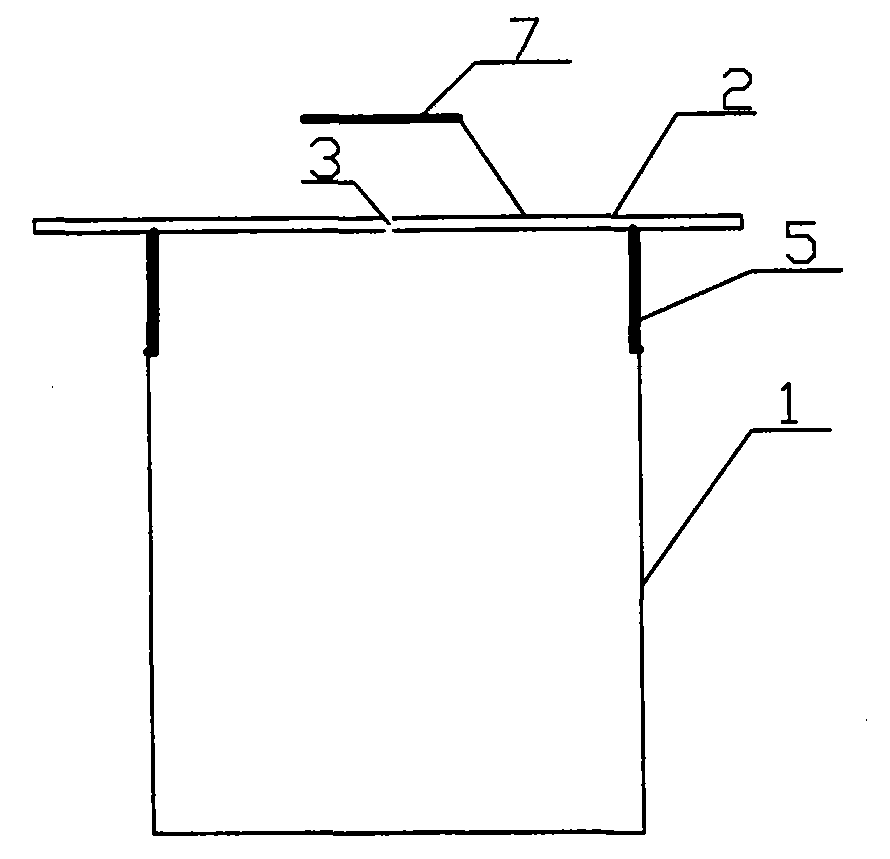

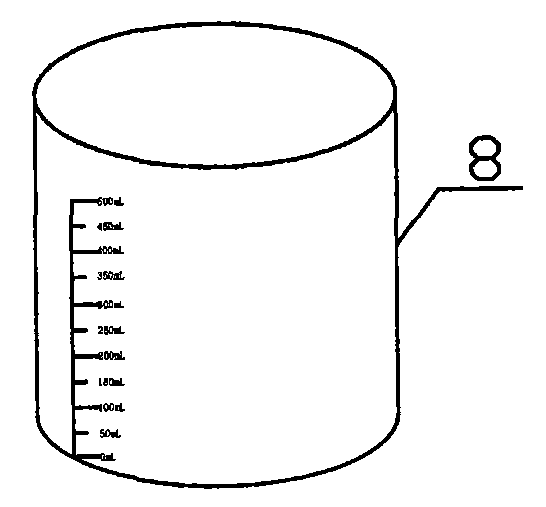

[0018] Such as figure 1 , figure 2 As shown, the sand material creeping collector is cylindrical, and the cylinder body 1 has a diameter of 200mm and a height of 250mm. Such as figure 1 , image 3 As shown, there is a sand inlet hole 3 in the center of the top cover surface, and the diameter of the sand inlet hole 3 is 6mm. The surface of the top cover 2 is covered with a layer of sand material 4 whose particle size is consistent with the research area. The diameter of the top cover 2 is 240mm, and a circle of inner edges 5 is fixedly welded under the top cover 2 . The inner edge 5 is 20 mm high and inserted into the cylinder body 1, and the sand-gathering funnel 6 is fixedly welded on the bottom of the top cover 2, and the sand-gathering funnel 6 communicates with the sand inlet hole 3. There is a dense mesh 7 at a height of about 20 mm above the top cover 2. The dense mesh 7 is welded on the top cover 2 by thin lead wires and is directly above the sand inlet hole 3. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com