Automobile rubber hose explosion testing machine

A blasting test and automobile rubber hose technology, which is applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of high price, complex structure of testing machine, inconvenient operation, etc., and achieve low cost, beautiful appearance and good structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, the present invention is described in further detail:

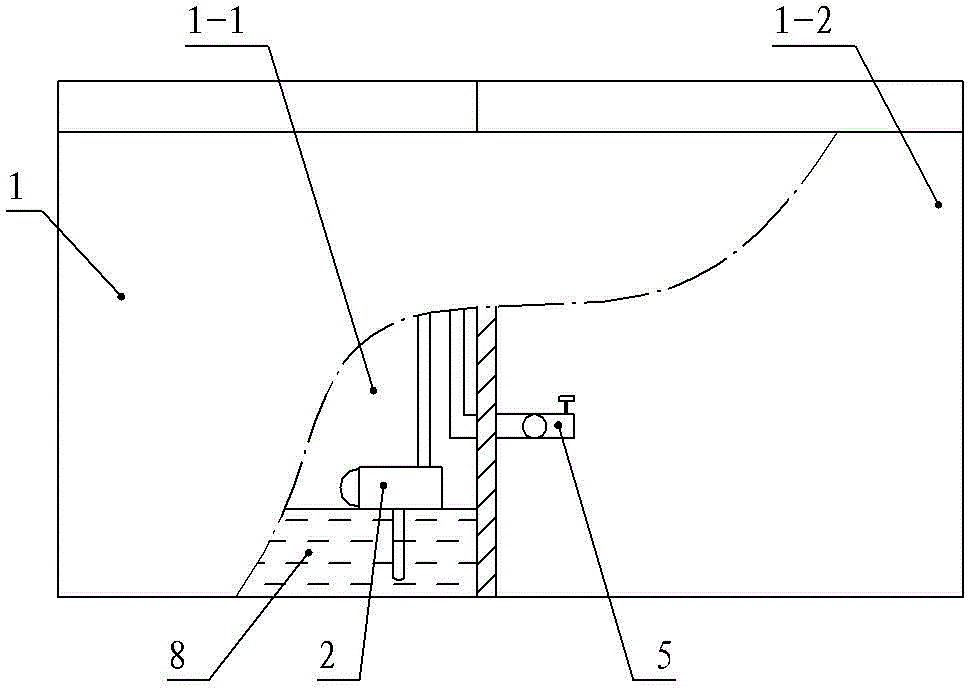

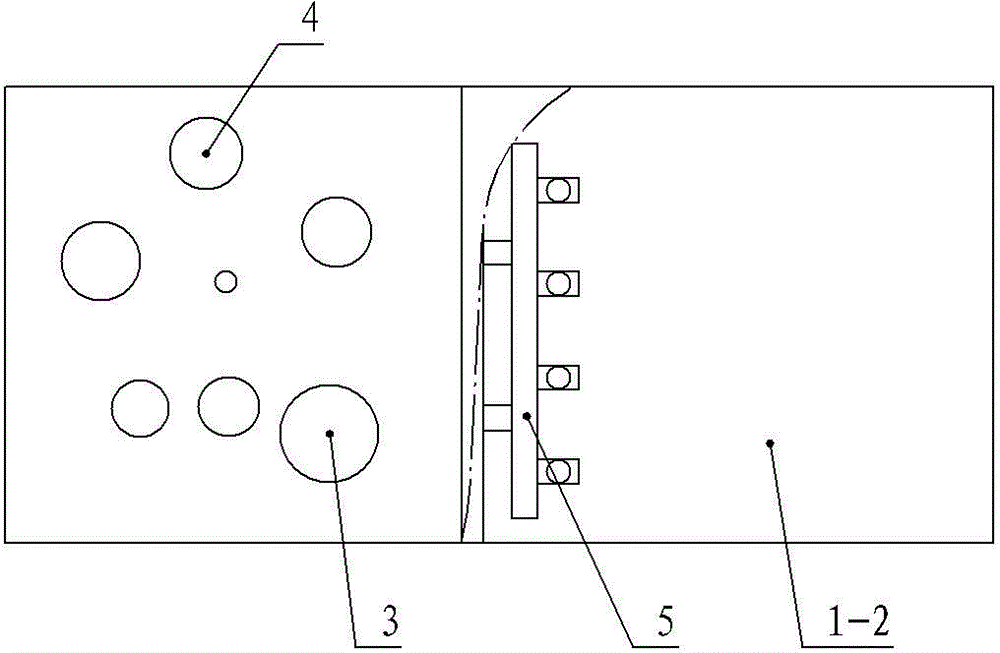

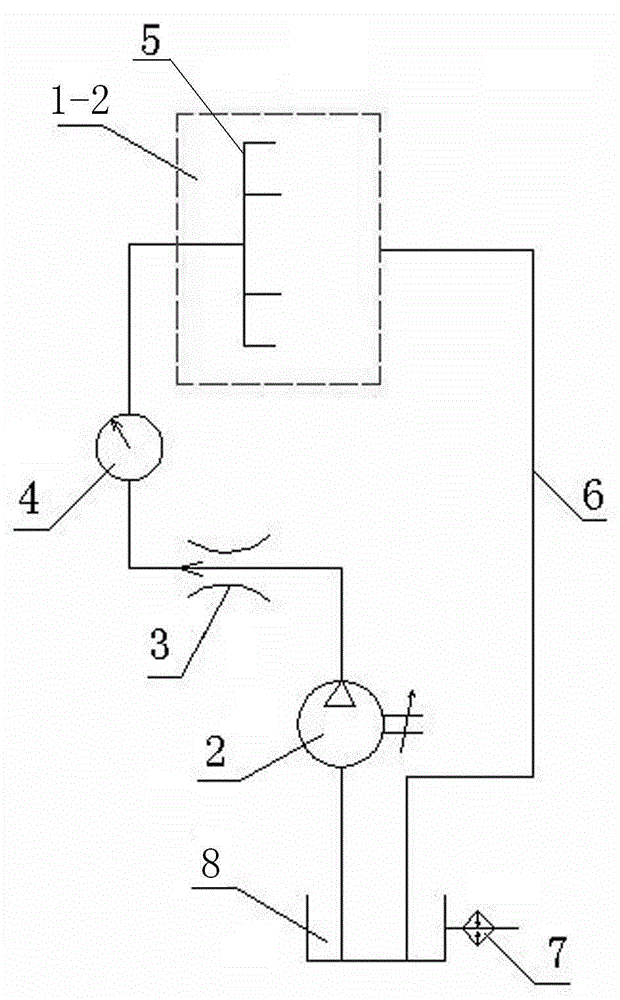

[0019] figure 1 , figure 2 and image 3 The automobile rubber hose blasting test machine comprises a box body 1 with a pressurization chamber 1-1 and a test chamber 1-2, and a water supply tank 8 and a water pump 2 are arranged in the pressurization chamber 1-1, and the water pump 2 adopts liquid pressurization Pump, this pump mainly completes the pressurization and pressure maintenance work of the present invention, which can ensure the pressurization and pressure maintenance of long-term tests; a control panel is arranged on the upper part of the pressurization chamber 1-1; a pressure regulating valve 3 is installed on the control panel And pressure gauge 4 and control buttons and indicator lights such as power switch, water pump control switch and adjustable temperature controller knob, can understand the change of various parameters in the test process and cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com