Device and method for detecting side surface of cylindrical object based on turntable assembly line

A technology of surface detection and detection method, which is applied in the direction of optical testing for flaws/defects, etc., can solve the problems of unguaranteed image quality, increase equipment complexity, and affect result judgment, etc., so as to facilitate the control system wiring and speed up the transmission speed , The effect of convenient wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

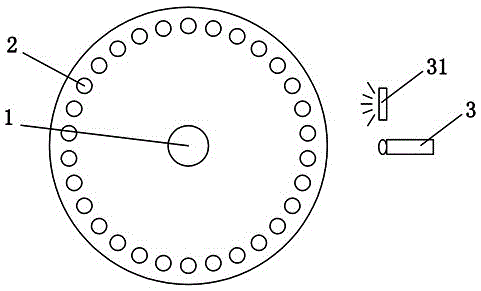

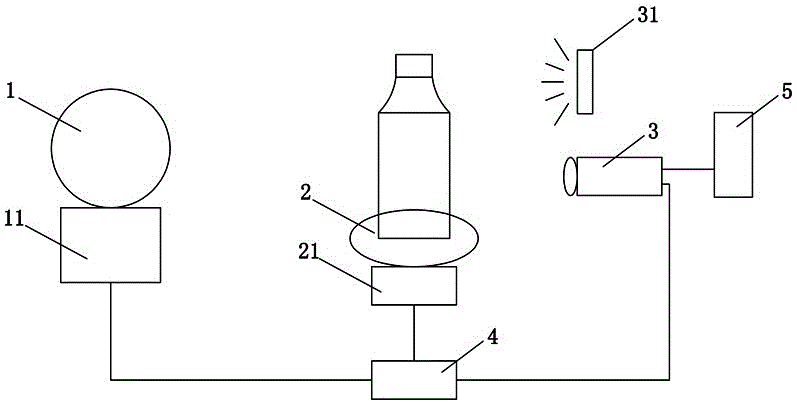

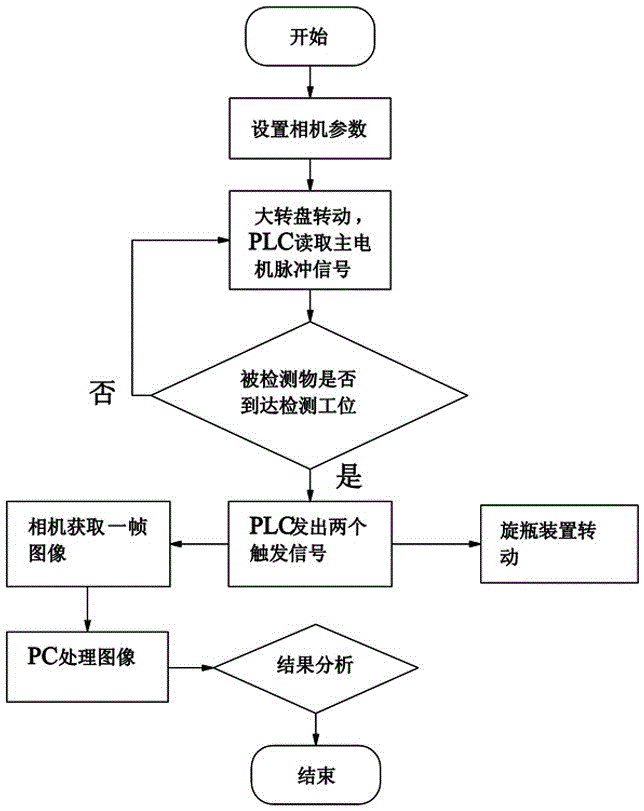

[0025] Figure 1 to Figure 2 Shown is a kind of cylindrical object side surface detection device embodiment based on the turntable assembly line of the present invention, and this cylindrical object side surface detection device includes a line scan camera 3, a turntable motor 1 for driving the turntable and several for driving The spin motor 2 corresponding to the spin device also includes a turntable motor encoder 11 installed on the turntable motor 1, a spin motor encoder 21 installed on the spin motor 2, and a data output connected to the line scan camera 3. The PC host 5 at the end and the PLC control system that sends a spin signal to the spin motor encoder 21 that reaches the shooting station according to the turntable rotation angle signal sent by the turntable motor encoder 11, and simultaneously sends a signal to the line scan camera 3 to collect a frame of image When the spin device of the shooting station completes one rotation, the line scan camera 3 completes one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com