Method for detecting microporous defect at heart part of cold-drawn seamless steel tube

A technology for seamless steel pipes and defects, which is applied in the preparation of test samples and the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, etc., to achieve the effect of improving the quality of objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

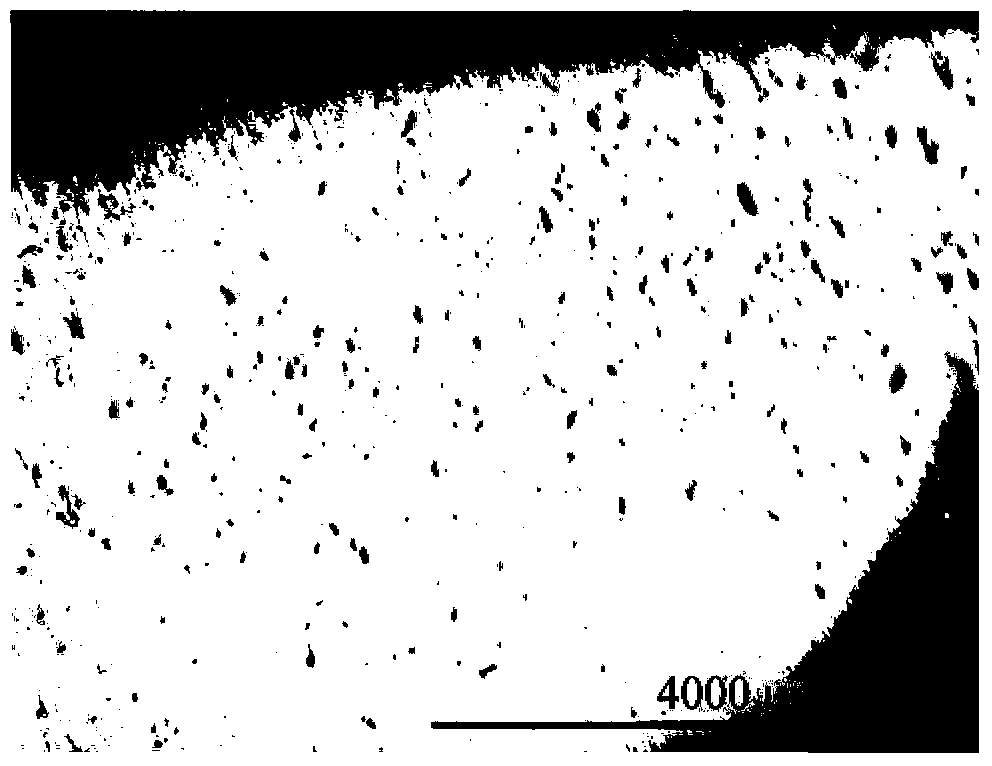

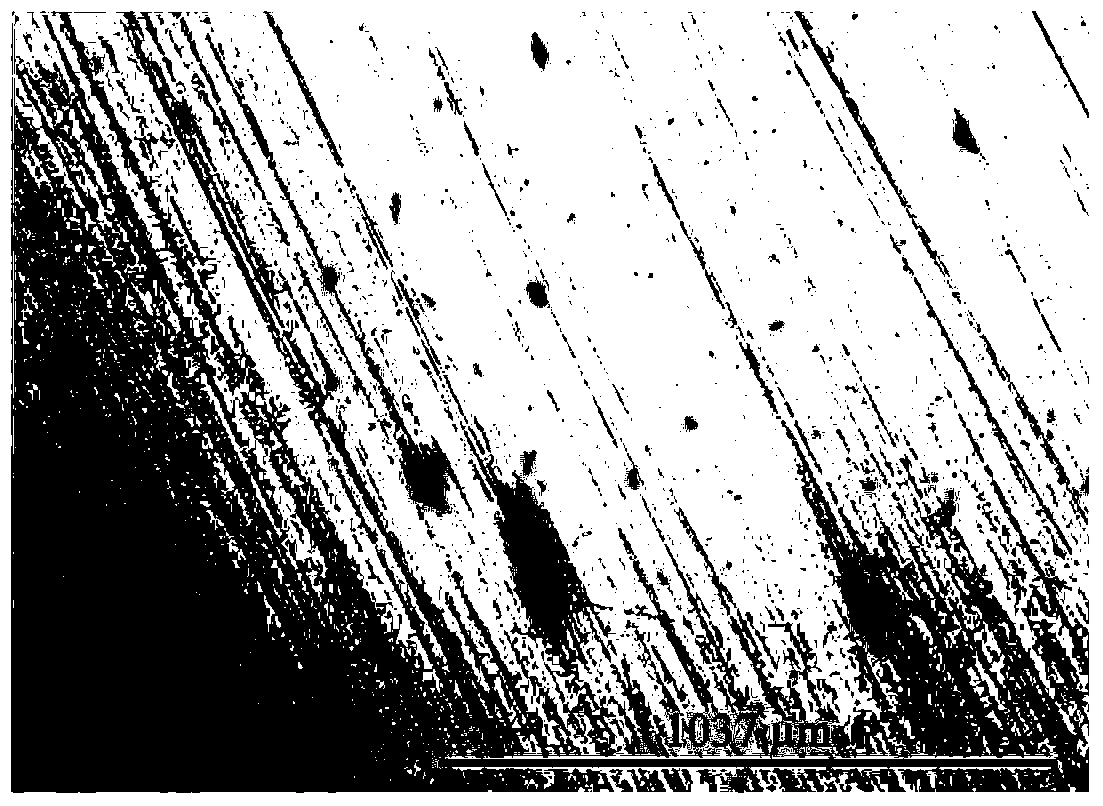

[0017] Hereinafter, the detection method of the microporous defect in the core part of the cold-drawn seamless steel pipe of the present invention will be described in detail with reference to exemplary embodiments.

[0018] In an exemplary embodiment of the present invention, the method for detecting microporous defects in the core of cold-drawn seamless steel pipe may consist of the following steps:

[0019] (1) Select the reference sample block

[0020] A section of steel pipe with the same specifications, material and surface state as the cold-drawn seamless steel pipe to be tested is selected as the reference sample block (abbreviated as sample block), and there are no microporous defects and other flaw detection defects inside the sample block. For example, select a section of steel pipe with the same specification, material and surface state as the cold-drawn seamless steel pipe to be tested as the sample block, and the elongation after fracture of the sample block is n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com