Connector assembly

A technology of connector assembly and locking assembly, which is applied in the direction of connection, parts of connecting device, two-part connecting device, etc., can solve the problems of rising production cost of connector assembly, influence of assembly efficiency, etc., to simplify the structure and improve assembly efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

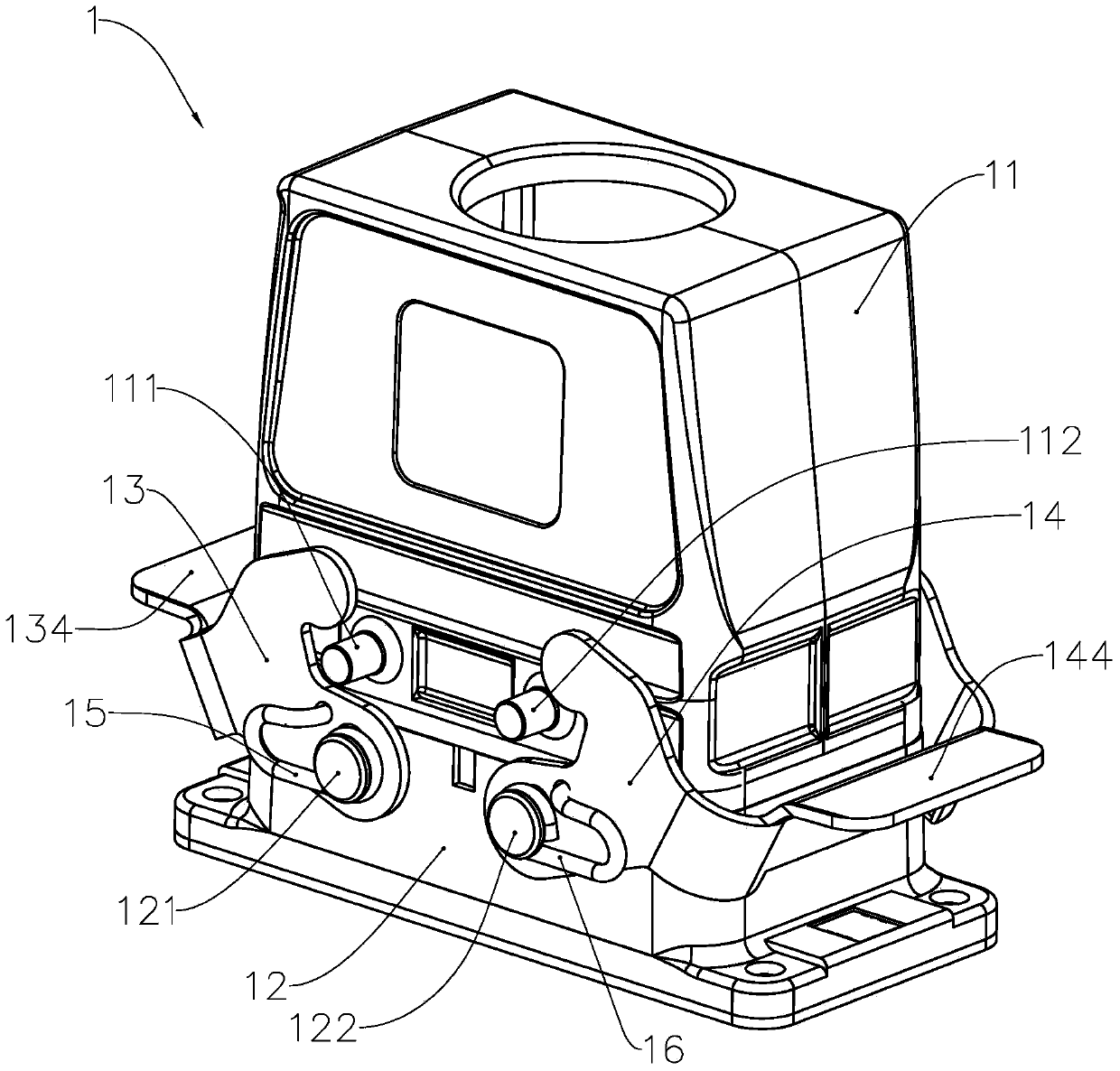

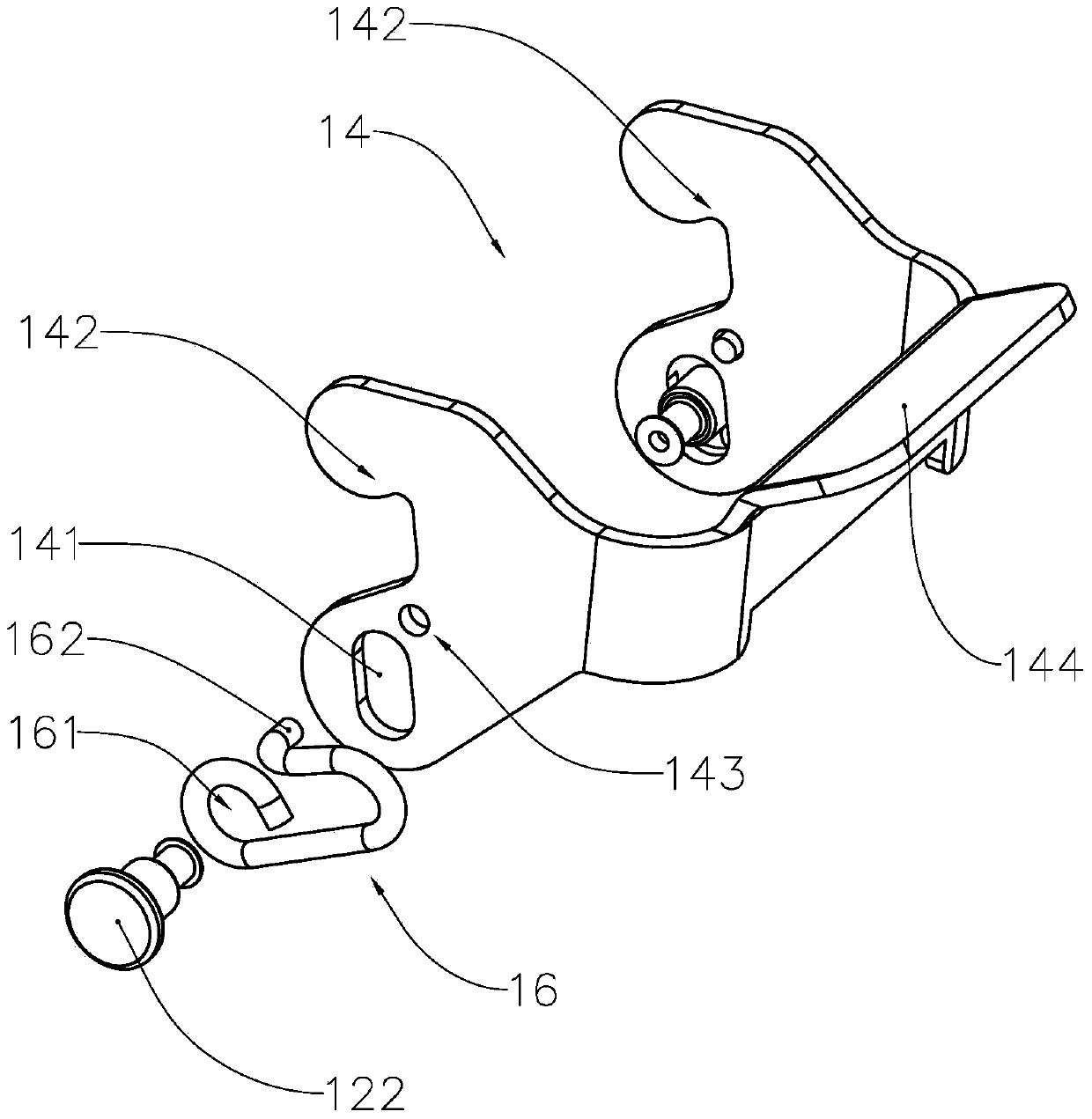

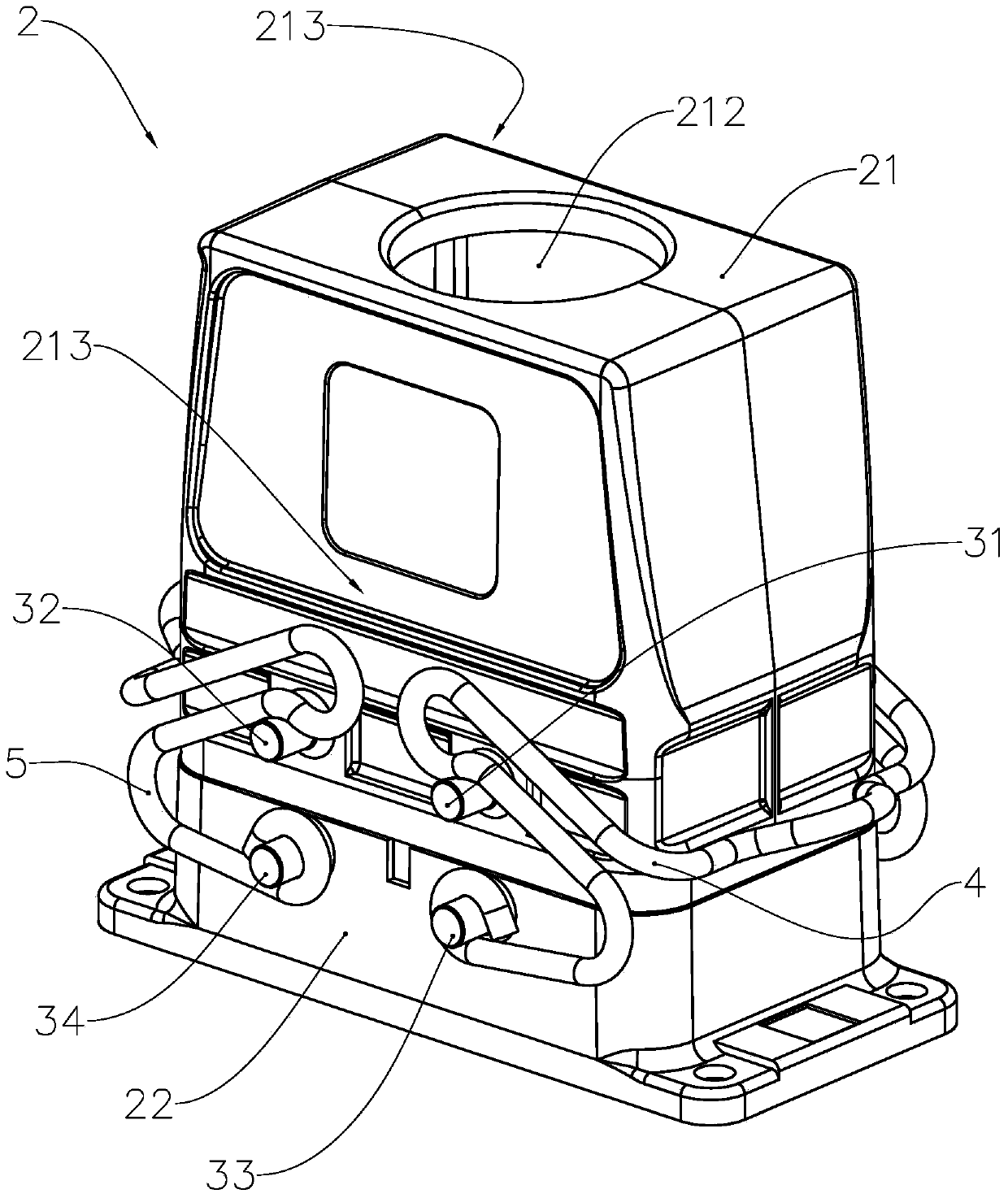

[0041] refer to image 3 , Figure 4 and Figure 5 , image 3 and Figure 4 is a structural diagram of the connector assembly 2 under different viewing angles, Figure 5is an exploded view of the connector assembly 2. The connector assembly 2 includes a plug 21, a receptacle 22 and two locking assemblies. The plug 21 includes a housing, which encloses a wire accommodation chamber, an opening 211 is opened at the lower end of the wire accommodation chamber, and an opening 211 is opened at the upper end of the wire accommodation chamber. Opening 212, a first wiring seat (not shown) is provided at the opening 211, and a cable hub (not shown) is provided at the opening 212. After the cable passes through the cable hub, the multiple wires in the cable respectively connected to the corresponding first wiring socket. The socket 12 includes a base, the base encloses a cavity for accommodating a wire socket, an opening 221 is opened at the upper end of the cavity, and a second wi...

no. 2 example

[0057] refer to Figure 10 , Figure 10 It is a structural diagram of the second embodiment of the connector assembly. On the basis of the first embodiment of the connector assembly, the locking member 5 can also be as Figure 10 In the structure shown, the difference between the locking member 5 and the locking member 4 lies in the setting of the operating part 55 and the positioning part 511. Compared with the operating part 45, the operating part 55 has a larger contact position, specifically, the operation The part 55 is arranged in a U-shaped structure, and the U-shaped operating part 55 has a protrusion 551 extending outward on the outer side of the side wall, and the protrusion 551 is arranged in a right-angled U-shaped structure, and the protrusion 551 and the operating part 55 are arranged on the same On the plane, it is beneficial to reduce processing difficulty and improve production efficiency. The U-shaped protrusion 551 with a larger contact position is used by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com