A kind of PU elastic environmental protection sole and its production method and production mold

A mold and environmental protection technology, applied in the field of shoe manufacturing, can solve the problems of easy shrinkage or elongation, only single color, difficult to produce two colors, etc., and achieve the effect of reducing the chance of hydrolysis, not easy to break and wrinkle, and easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

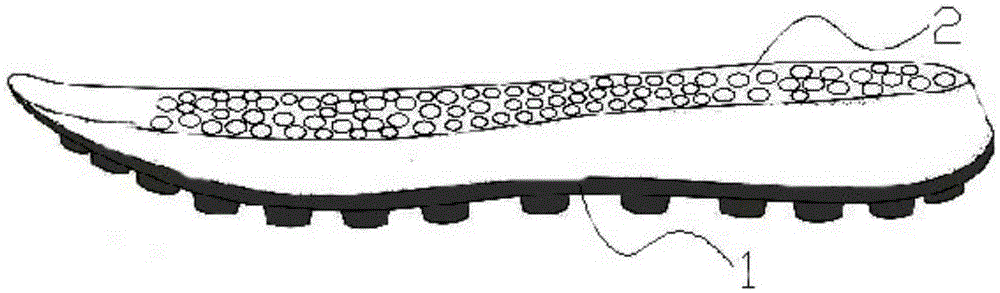

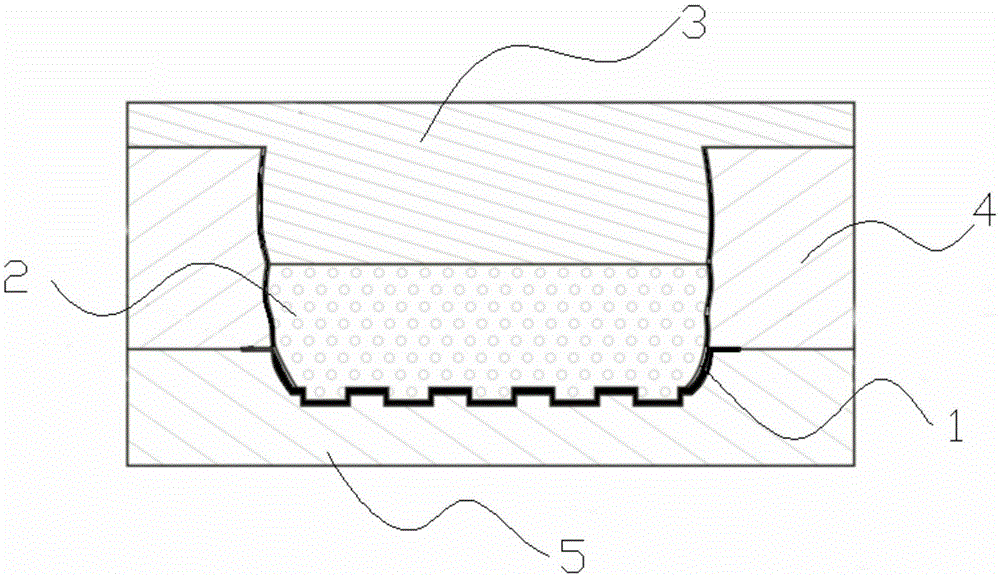

[0029] Such as figure 1 As shown, a kind of PU elastic environment-friendly sole of the present invention includes a large bottom 1 and a midsole 2; the large bottom 1 is in the shape of a sheet, and the large bottom 1 is indented downward to form a plurality of depressions; the middle bottom The bottom 2 is a PU foam layer, and the midsole 2 is provided with two cushioning parts, and the midsole 2 is also provided with ventilation holes; the midsole 2 is completely attached to the outsole 1 .

[0030] Preferably, the midsole 2 is respectively provided with a cushioning piece at the position of the sole and the heel. Specifically, in this embodiment, the buffer member is a circular steel ring.

[0031] In order to ensure that the sole is wear-resistant and wear-resistant, and prolong the service life of the sole, on the basis of the above-mentioned embodiments, in a preferred embodiment, the material of the outsole 1 is TR, TPU, TPE, PVC, TPR, EVA, PU, A kind of rubber.

[...

specific Embodiment 2

[0044] Such as figure 1As shown, a kind of PU elastic environment-friendly sole of the present invention includes a large bottom 1 and a midsole 2; the large bottom 1 is in the shape of a sheet, and the large bottom 1 is indented downward to form a plurality of depressions; the middle bottom The bottom 2 is a PU foam layer, and the midsole 2 is provided with two cushioning parts, and the midsole 2 is also provided with ventilation holes; the midsole 2 is completely attached to the outsole 1 .

[0045] Preferably, the midsole 2 is respectively provided with a cushioning piece at the position of the sole and the heel. Specifically, in this embodiment, the buffer member is a circular steel ring.

[0046] In order to ensure that the sole is wear-resistant and wear-resistant, and prolong the service life of the sole, on the basis of the above-mentioned embodiments, in a preferred embodiment, the material of the outsole 1 is TR, TPU, TPE, PVC, TPR, EVA, PU, A kind of rubber.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com