Roller assembly of sand screening machine

A technology of sand sieving machine and sieve cylinder, applied in the direction of sieve, solid separation, grille, etc., can solve the problems such as the inability of automatic discharge of pebbles, complex overall structure, poor screening effect, etc., to achieve simple structure, improve economic benefits, The effect of increasing work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

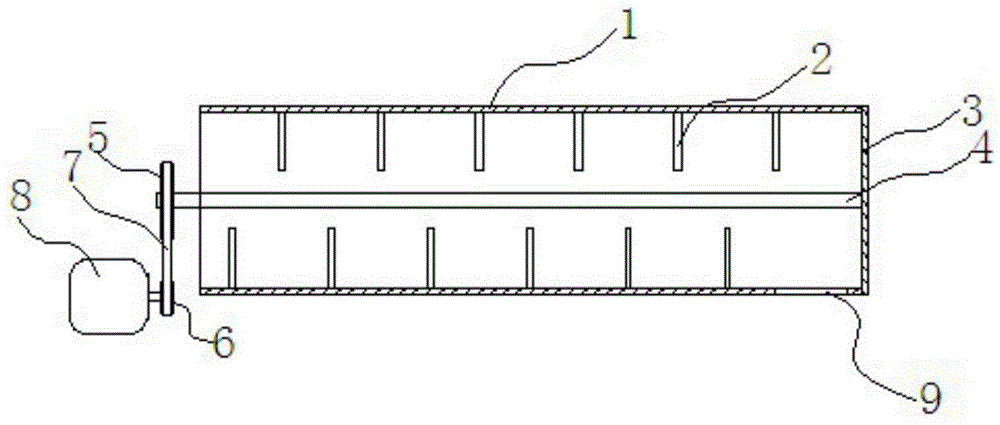

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention.

[0013] see figure 1 , the specific embodiment is realized by adopting the following technical scheme, which includes a screen cylinder body 1, a circle of helical circle 2 is arranged on the inner wall of the screen cylinder body 1, and a steel plate 3 is welded on the end surface of one end thereof, and the screen cylinder body 1 is provided with a rotating shaft 4 concentric with it, one end of the rotating shaft 4 is fixedly connected with the steel plate 3, and the other end is sleeved and fixed with a driven pulley 5, and the driven pulley 5 is connected to the driving pulley through the belt 7 6, and the driving pulley 6 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com