Material-jump-preventing device for small holes

An anti-jumping material and template technology, applied in stripping devices, perforating tools, metal processing, etc., can solve the problem of small hole clogging, achieve simple processing, improve the effect of skipping waste and small hole clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings.

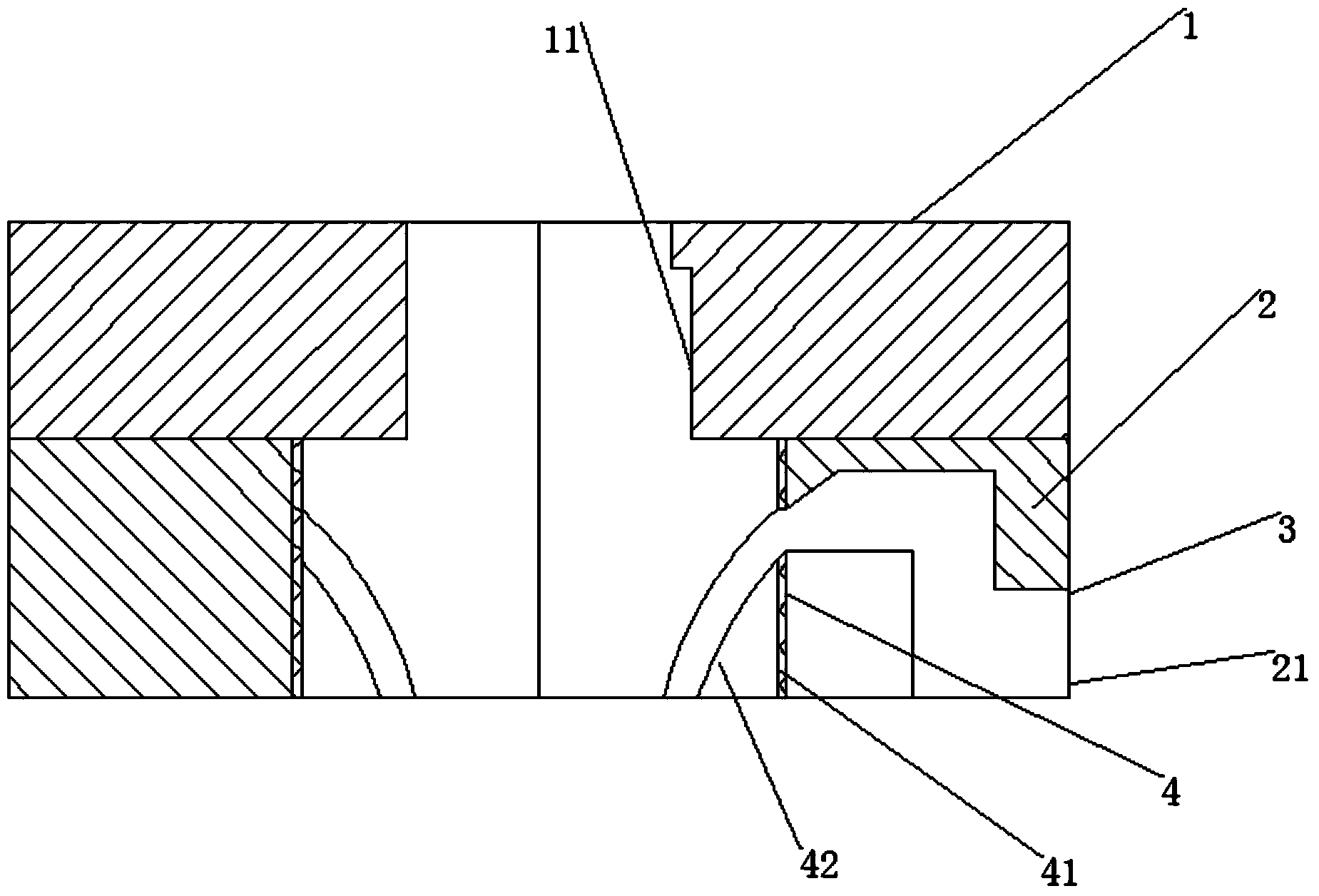

[0018] See figure 1 A small hole anti-skip device of this embodiment includes a lower template 1, a lower backing plate 2 is provided under the lower template 1, and the lower template 1 is provided with a first through hole for punching small holes, and the lower backing plate 2 A second through hole is provided below the first through hole. The lower backing plate 2 is provided with a first groove 21. The first groove 21 is provided with a flexible air pipe 3 and a fixing device for fixing the flexible air pipe 3, the flexible air pipe 3 The outlet end of the valve is bent downward and communicates with the second through hole.

[0019] In the prior art, the lower template 1 and the lower backing plate 2 are provided with air inlets. Due to the extremely irregular shape and direction of the air inlets, it is difficult to process and cannot be used flexibly. The lower bac...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap