Method for closing in self-locking nut

A self-locking nut and consistent technology, applied in the direction of nuts, threaded fasteners, connecting components, etc., can solve the problems of inconsistent wall thickness of self-locking nuts, deviation of locking force, etc., and achieve simple measurement devices and methods, and eliminate locking The effect of force deviation, improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

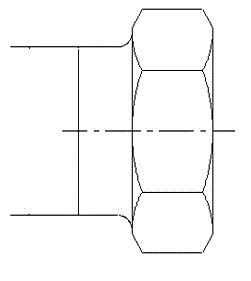

[0014] A self-locking nut closing method will be described below, and the specific implementation will be repeated below; the present invention controls the force value of the positive pressure when the part is closed through the force sensor, so that the parts can produce different deformations, but the results are the same deformation resistance. This consistent deformation resistance ensures consistent locking force values. Such a closing method can ignore the influence of the change of the closing length within a certain range on the locking force, and the influence of the uneven wall thickness of the closing position on the locking force during part processing.

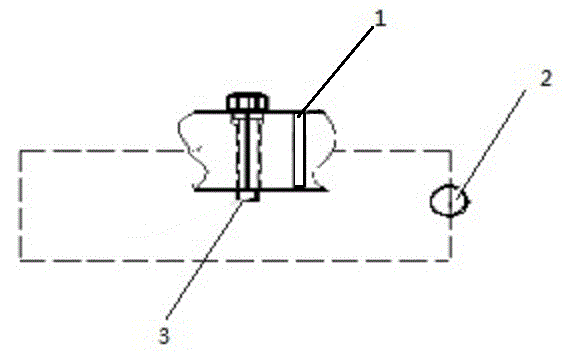

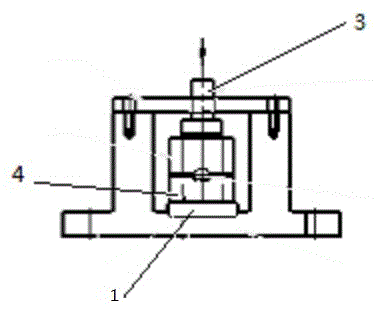

[0015] The technical solution of the present invention: the measuring device involved in the present invention includes: a force sensor 1 ; a controller 2 ; an afterburner rod 3 ;

[0016] The original closing tooling is basically unchanged. Using the measuring device, a force sensor 1 is added behind the booste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com