Method and system for measuring density of desulfurization slurry in power plant desulfurization pre-washing tower

A desulfurization slurry and measurement method technology, which is applied to determine the specific gravity and other directions by measuring the pressure difference, can solve the problems of large wear of pipeline valves, easy drift of zero point, waste of electric energy, etc., and achieve simple structure, simplified measurement process and improved measurement accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

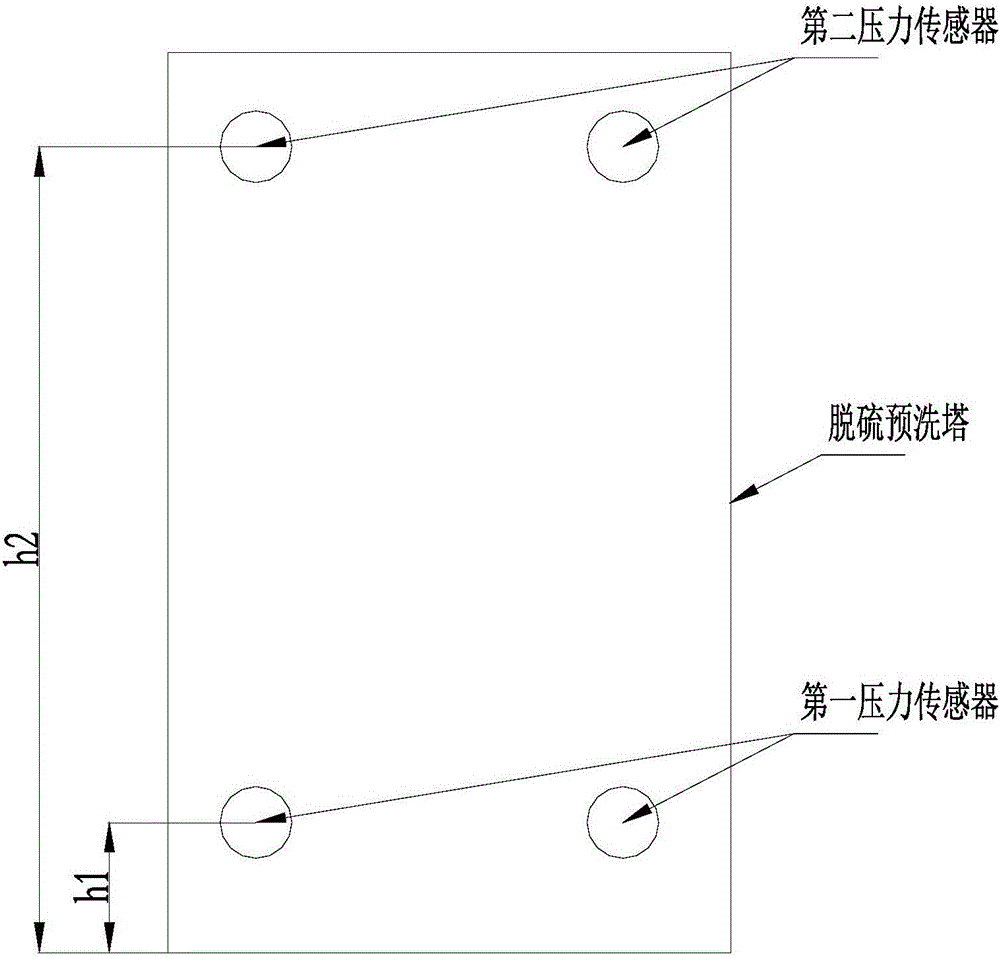

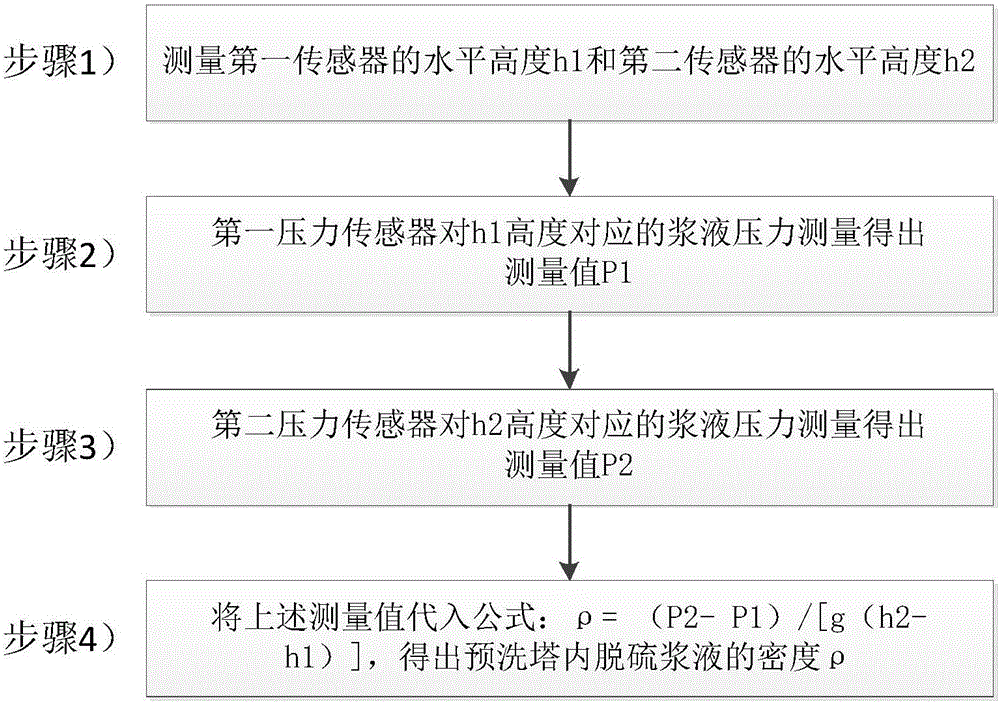

[0036] Such as figure 1 As shown, in this embodiment, the pressure sensor includes a first pressure sensor set near the first level h1 at the bottom of the pre-washing tower, and a second pressure sensor set near the second level h2 at the top of the pre-washing tower .

[0037] Such as Figure 4As shown, in this embodiment, a group of first pressure sensors is provided at the first horizontal height h1 of the pre-washing tower, and one group includes at least two first pressure sensors, and each first pressure sensor is equally spaced relative to the axis of the pre-washing tower The arrangement of angles is installed on the outer wall of the pre-washing tower; a group of second pressure sensors is arranged at the second level h2 of the pre-washing tower, and one group includes at least two second pressure sensors, and each second pressure sensor is relatively pre-washed. The tower axis is arranged at equal intervals and angles and installed on the outer wall of the pre-was...

Embodiment 2

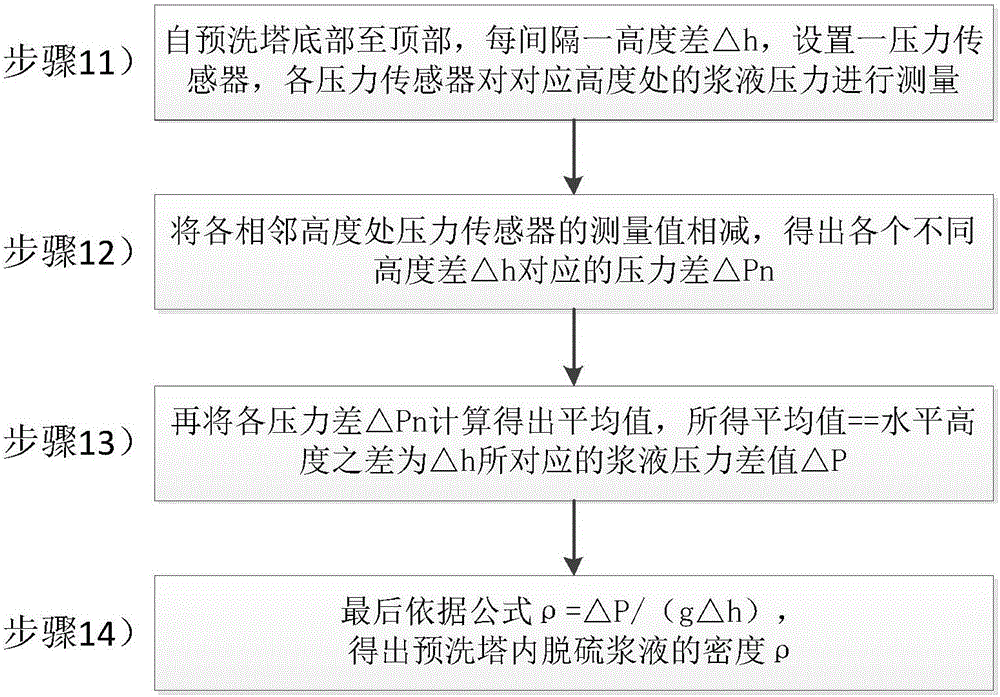

[0059] Such as Figure 5 As shown, in this embodiment, at least two groups of first pressure sensors at different levels are arranged on the pre-washing tower, and a group of corresponding second pressure sensors is set above each group of first pressure sensors with a height difference Δh. sensor.

[0060] By setting multiple sets of corresponding first pressure sensors and second pressure sensors on the pre-washing tower, the pressure difference corresponding to the same height difference △h at different heights can be accurately measured respectively, so as to improve the height difference △ h corresponds to the measurement accuracy of the pressure difference for further elimination.

[0061] In this embodiment, at least two first pressure sensors at different levels are arranged on the pre-washing tower, and a corresponding second pressure sensor is arranged above each first pressure sensor with a height difference Δh. The difference △Pn between the measured value of the...

Embodiment 3

[0071] The difference between this embodiment and the second embodiment above is that: from the bottom to the top of the pre-washing tower, a certain height difference △h1, △h2...△hn is set at each interval, and a pressure sensor is set. Based on the measured values of each pressure sensor, it is obtained Different height differences △h1, △h2…△hn correspond to desulfurization slurry pressure differences △P1, △P2…△Pn; and then according to the formula ρ=△P / (g△h), the desulfurization slurry in the prewashing tower is obtained respectively Density ρ1, ρ2...ρn; finally calculate the average value of ρ1, ρ2...ρn, the average value = the density ρ of the desulfurization slurry in the pre-washing tower.

[0072] By measuring the concentration of desulfurization slurry at different heights of the pre-washing tower, the concentration of desulfurization slurry is calculated respectively, and then the average value of each concentration is calculated to further improve the accuracy of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com