Annular long casting member spiral shower casting method

A casting and spiral technology, which is applied in the field of the spiral rain pouring method for annular long castings, can solve the problems of difficult release, economic loss, complex structure, etc., and achieve the effects of ensuring quality and improving yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

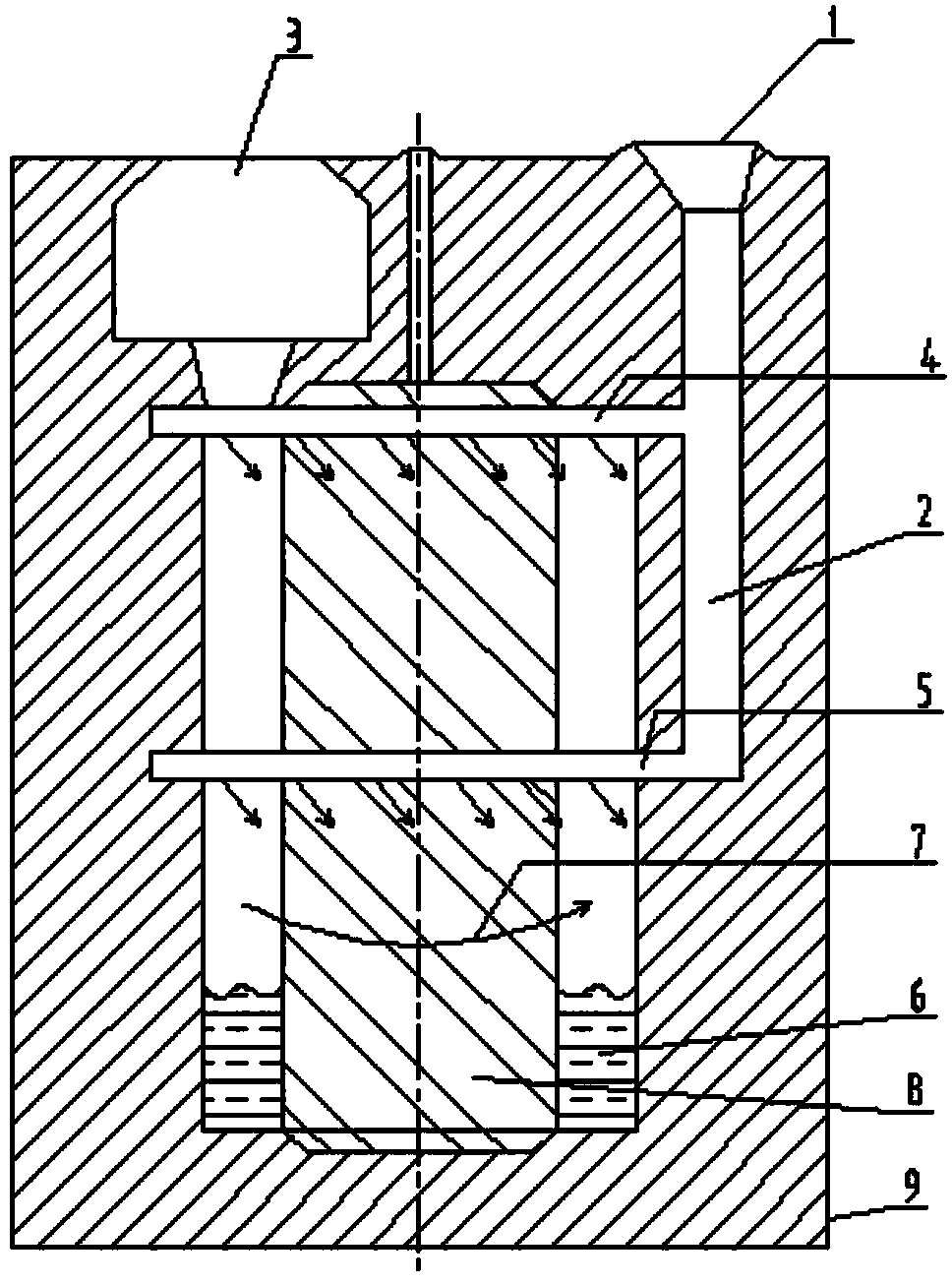

[0009] Refer to the attached picture, 1. Sprue gate 2. Vertical runner 3. Cap mouth 4. Upper pouring ring 5. Lower pouring ring 6. Liquid iron 7. Liquid iron floating and rotating direction 8. Sand core 9. Molding sand box

[0010] In the spiral rain pouring method of circular long castings, the casting model is vertically fixed in the molding sand box, and a single-layer or multi-layer pouring ring is arranged on the casting model, and the longitudinal direction of the casting ring is spiral. A number of spiral sprues are evenly distributed around. The upper end of the pouring ring is connected to the sprue. When pouring, the vertical pouring method is adopted, and the molten iron is poured slowly from the sprue. The molten iron enters the cavity through the pouring ring 360°, and the The surface rotates in a spiral shape and floats up to the upper end of the model, and then cools and forms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com