Hot runner nozzle of pin-point gate

A hot runner nozzle and point gate technology, applied in the field of point gate hot runner nozzles, can solve the problems of large flow resistance, poor fluidity, and inability to change colors quickly, and achieve smooth flow, high practicability, and rapid change. color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

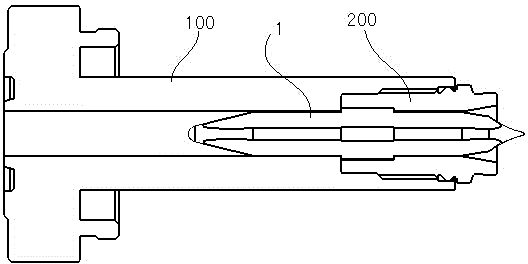

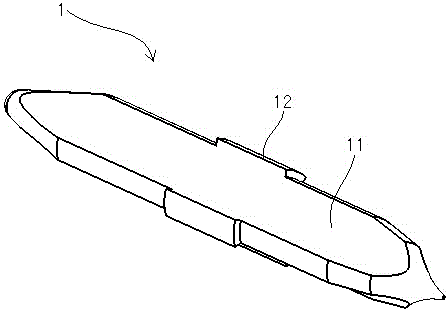

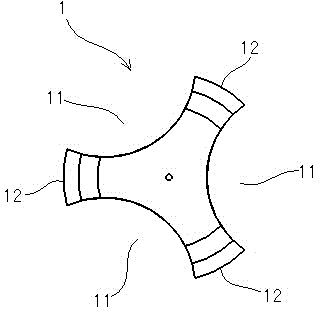

[0016] refer to figure 1 As shown, a point gate hot runner nozzle includes a sprue bushing 200 coaxially connected to one end of the nozzle body 100, and a torpedo nozzle core 1 is coaxially connected to the sprue bushing 200, and the torpedo nozzle core 1 is Shuttle-shaped structure, three arc-shaped runners 11 are opened on the surface in the axial direction, and one end of the torpedo nozzle core 1 is arranged outside the sprue sleeve 200 .

[0017] The torpedo nozzle core 1 is clamped in the step formed between the sprue bushing 200 and the nozzle body 100 through the boss 12 provided on the outer edge of the middle part.

[0018] The nozzle body 100 cooperates with the heater to maintain a constant temperature, and is connected to the flow channel of the diverter plate to provide a flowable channel for the plastic material. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com