Three-layer composite pipe production mold

A composite pipe and mold technology, which is applied in the field of three-layer composite pipe production molds, can solve the problems of inconsistent casting, scale deposition, difficult synthesis, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

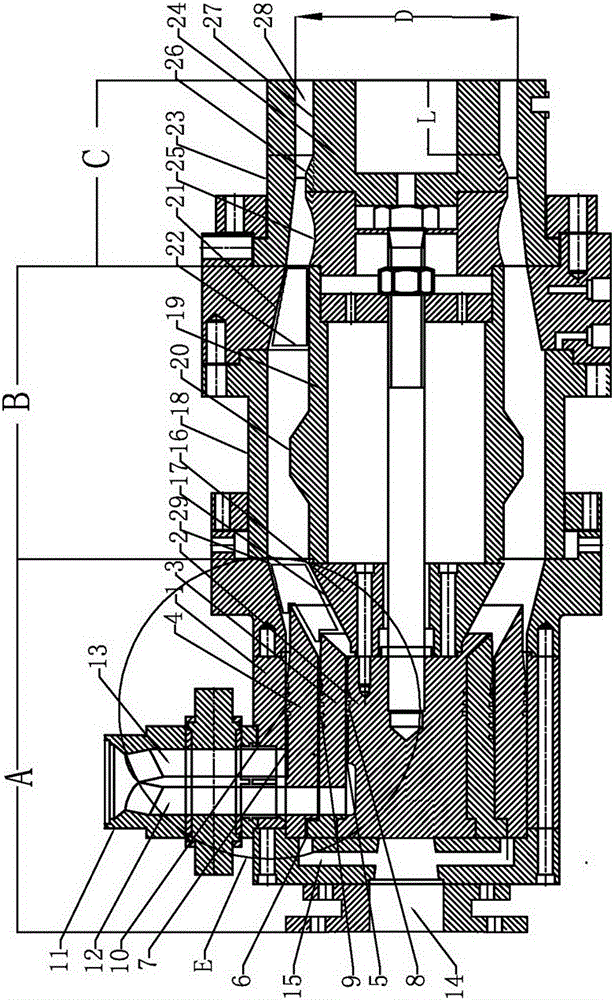

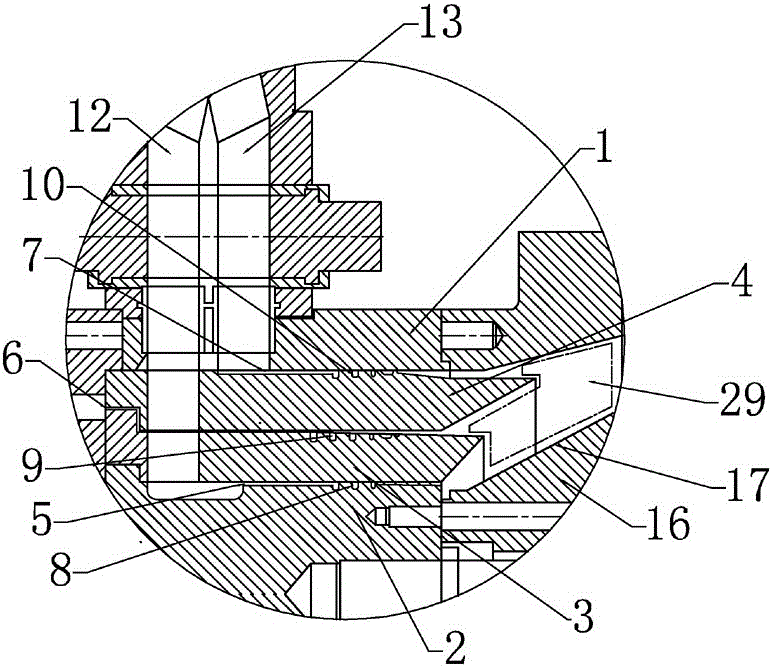

[0027] Embodiment 1, a kind of three-layer composite pipe production mold, see figure 1 , including a split flow synthesis mold A, a plasticized compression mold B, and a shaping mold C that are sequentially connected. The split synthetic mold A includes an outer cylinder body 1, an inner layer feed body 2, a middle layer feed body 3, and an outer layer feed body 4, which are arranged in the outer cylinder body and are sequentially nested from the inside to the outside. A material flow channel 5 is left between the inner layer feed body 2 and the middle layer feed body 3, a material flow channel 6 is left between the middle layer feed body 3 and the outer layer feed body 4, and the outer layer feed body 4 There is a material flow channel 7 between the inner wall of the outer cylinder body 1, and spiral grooves 8, 9, 10. The depths of the spiral grooves 8, 9, and 10 gradually become shallower from the inlet of the spiral groove to the outlet of the spiral groove. The above de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com