Hinged mounting base on 100% modern city tramcar

A technology for trams and mounting seats, applied in transportation and packaging, railway car body parts, railway couplings, etc., can solve the problems of non-replacement and non-repairability, and achieve easy repair and replacement, reduce weight, and meet The effect of strength indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

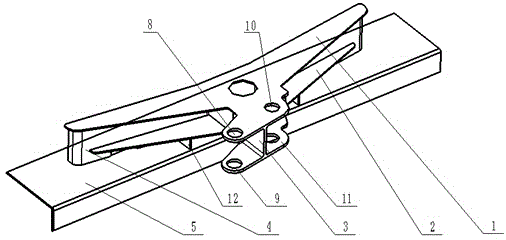

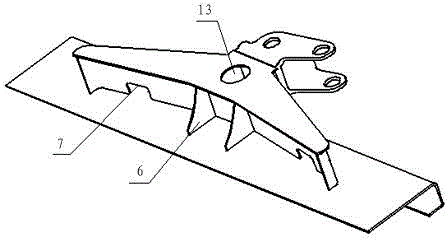

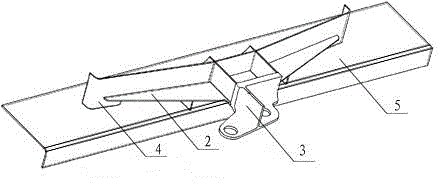

[0028] Below in conjunction with accompanying drawing, the present invention is described in detail.

[0029] Such as figure 1 Described, a kind of 100% modern urban tram upper hinged mounting seat, comprises upper panel 1, lower panel 2, connecting rib 3, rear blocking plate 4, base 5, and described connecting rib 3 is welded respectively Connect the upper panel 1, the lower panel 2, and the rear blocking plate 4, the upper panel 1, the lower panel 2 are welded on the rear blocking plate 4, the rear blocking plate 4 is welded on the base 5, and the base 5 is provided with a useful For the holes for riveting, the holes for riveting are distributed at both ends of the base 5 .

[0030] The upper panel 1 is provided with a first buffer installation hole 8 and a first upper hinge installation h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com