A Measuring Method of Coal Injection Quantity of BF Coal Injection System

A technology of blast furnace coal injection and metering method, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as difficult maintenance, complex on-site control, and many pipelines, so as to improve accuracy, avoid tank weight fluctuations, and highlight the essence The effect of sexuality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical solution and advantages of the present invention clearer, the technical solution of the present invention will be clearly and completely described below in conjunction with specific embodiments.

[0033] A method for measuring the amount of coal injection in a blast furnace coal injection system of the present invention comprises the steps of:

[0034] (1) At a certain moment as the starting timing point, collect and record the weight of the spray tank at this timing point, and then record the collection time point and the weight of the spray tank every 1s, and record the above collection time points in chronological order denoted as t in turn 1 , t 2 ,...,t n , n≥10, and n∈N, record the weight of the blowing tank recorded above as g 1 , g 2 ,..., g n , and n∈N.

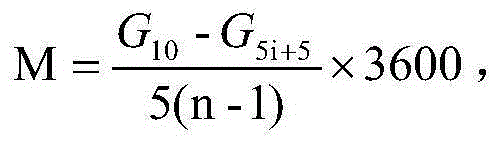

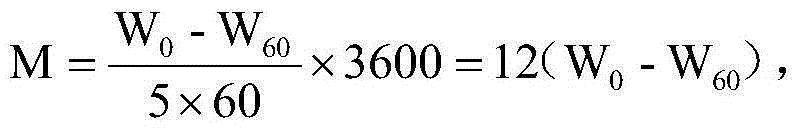

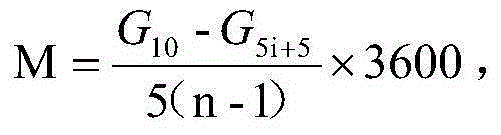

[0035] (2) Calculate the average weight G of the spray tank according to the formula ① n , and the mean weight G n As the above acquisition time point t n The actual wei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com