Online gas pressure-tapping method and online gas pressure-tapping device

A technology of gas and gas pipelines, which is applied in the direction of measuring devices, measuring fluid pressure, instruments, etc., can solve problems such as damage, no isolation measures, and large fluctuations in pressure data, so as to achieve accurate and reliable equipment operation, equipment intrinsically safe, and data The realism-enhancing effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

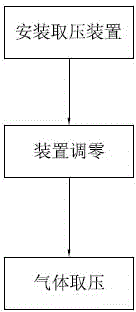

[0033] Such as figure 2 A kind of gas online pressure taking method of the present invention shown, comprises the following steps:

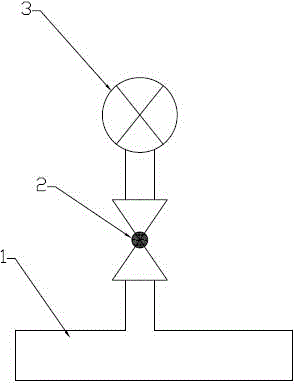

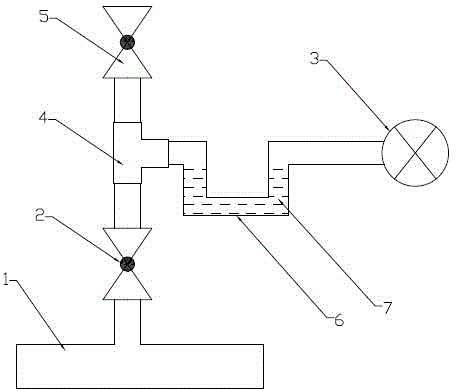

[0034] 1) Installation process: Open a hole in the appropriate position of the gas pipeline, the size of the hole is between 17mm-20mm, weld a D15 pipe fitting with wire at one end, and install the main ball valve 2 (Q11F-16C, DN15mm) at the other end with the wire, after the main ball valve 2 Connect the D15 paired wire fittings, install D15 tee 4 after the paired wire fittings, and then connect the D15 paired wire fittings to the vertical port of the tee 4, install D15 auxiliary ball valve 5 after aligning the wire fittings, and connect the horizontal port of the tee 4 to a U-shaped pipe with a diameter of 15mm After the pipeline 6 and the U-shaped pipeline are filled with the spacer fluid 7, the pressure transmitter 3 is installed.

[0035] Among them, the U-shaped pipeline 6 is made of seamless steel pipe or copper pipe; when filling the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com